- Albanian

- Arabica

- Armeniaca

- Azerbaigiana

- Belarusian

- Bengalica

- Bulgarica

- Croatian

- Bohemica

- Danica

- Batavus

- Anglice

- Esperanto

- Finnica

- Francogallica

- German

- Greek

- Hebraea

- Hungarica

- Indonesiana

- Hibernicus

- Italian

- Iaponicus

- Khmer

- Coreana

- Kyrgyz

- Labor

- Latina

- Lithuanian

- Malay

- Myanmar

- Norvegica

- Persica

- Polonica

- Portuguese

- Romanian

- Russian

- Serbian

- Slovaca

- Slovenian

- Hispanica

- Suecica

- Tagalog

- Thaiensis

- Turcica

- Turcomanicus

- Uzbek

- Vietnamica

- Zulu

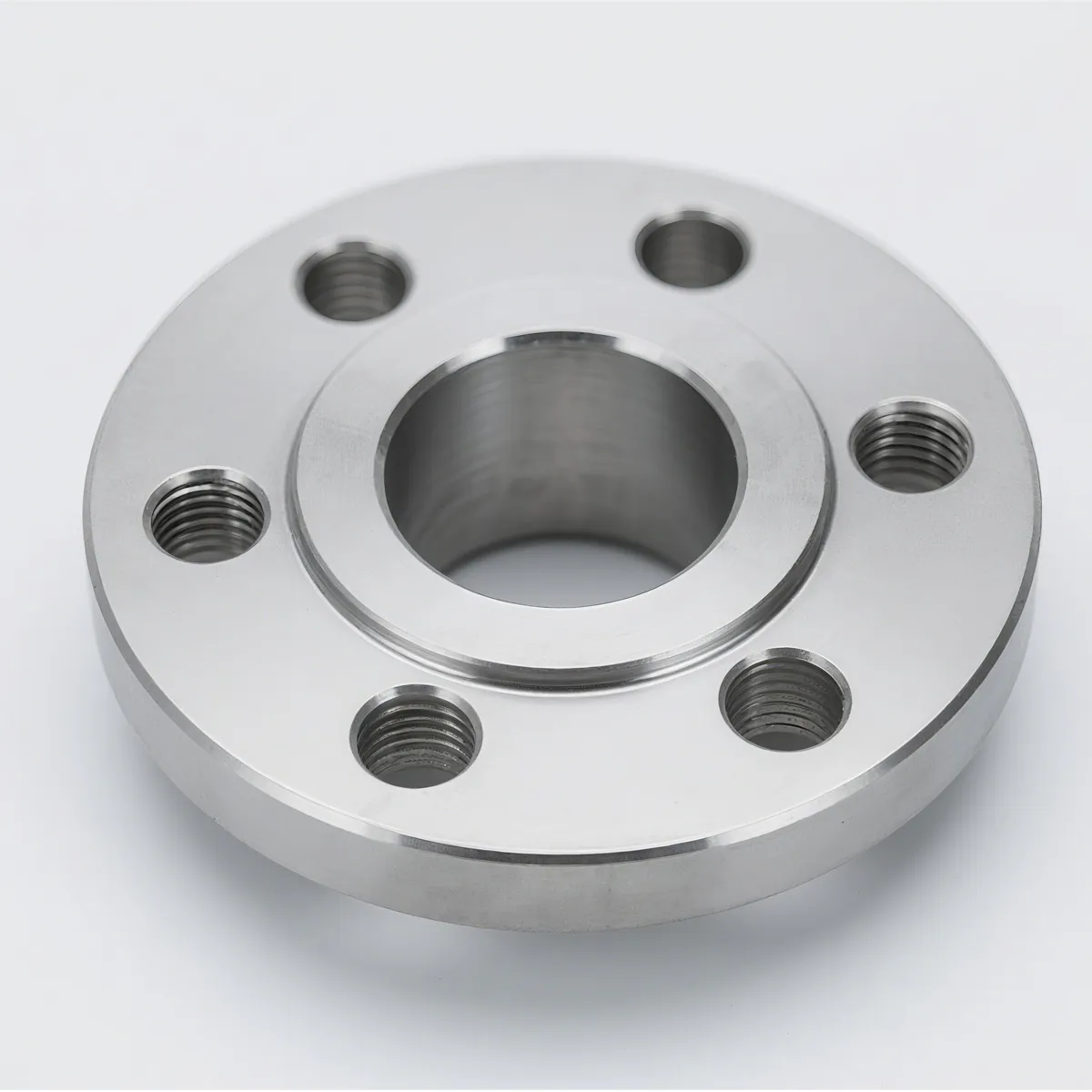

Introduction to Slip-On Weld Flanges

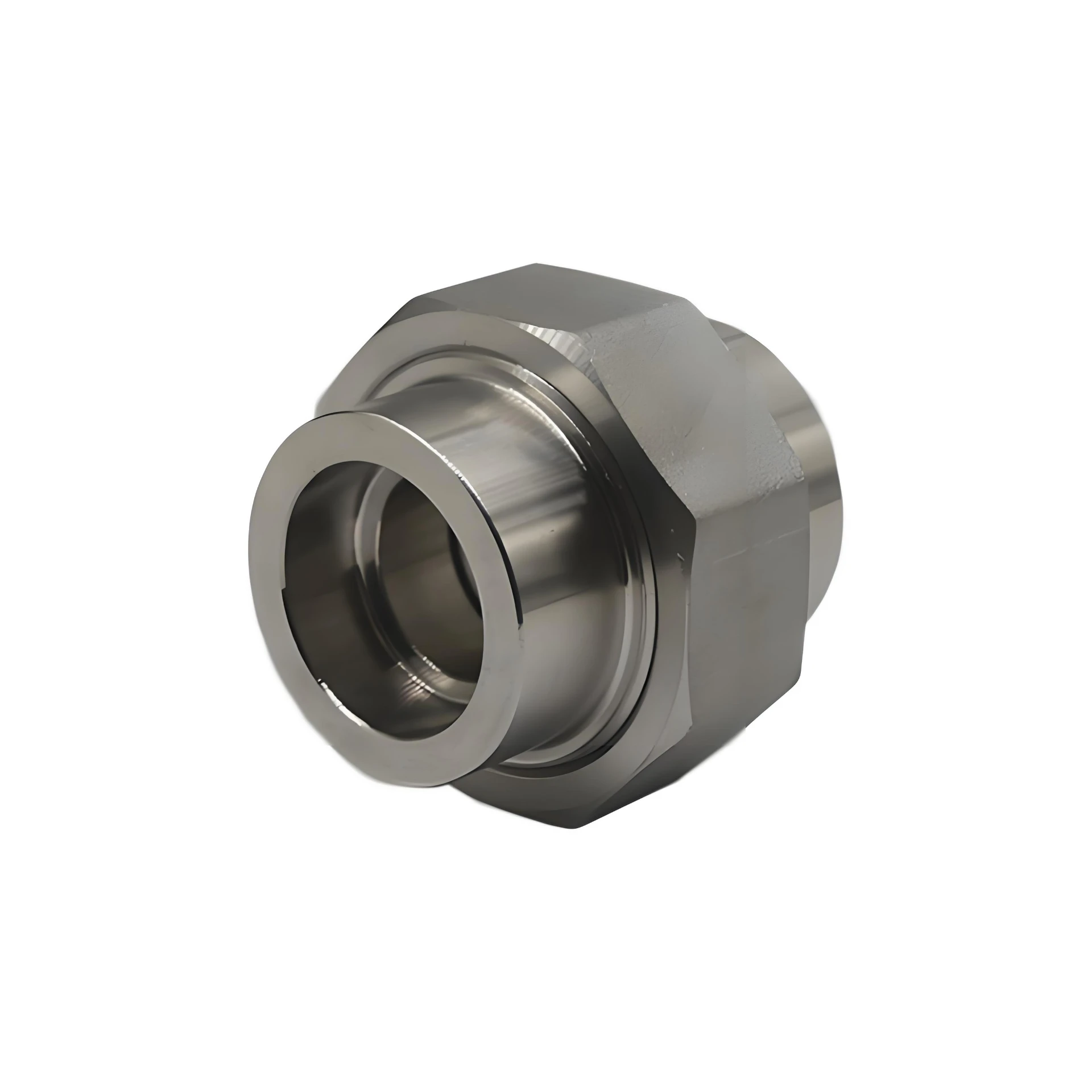

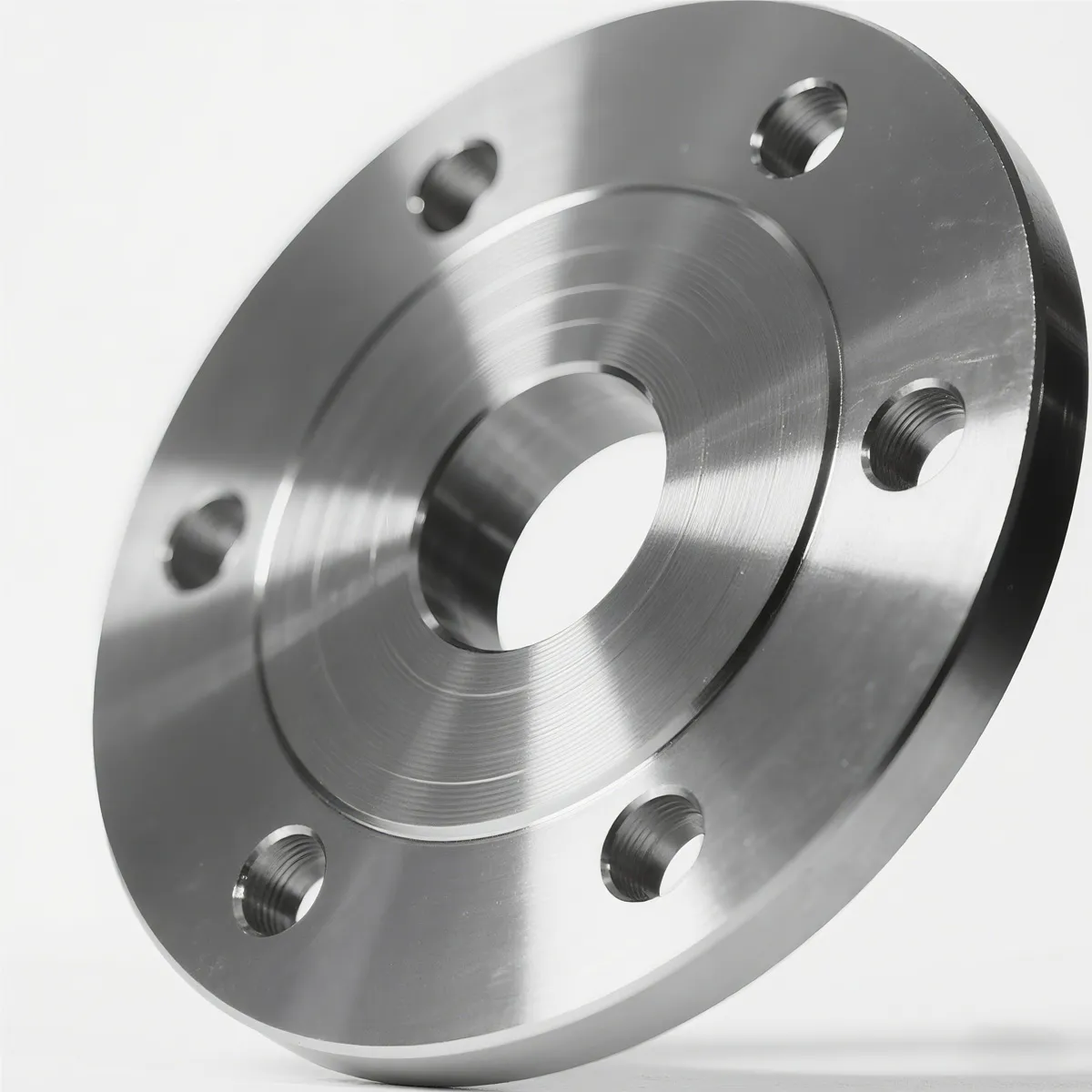

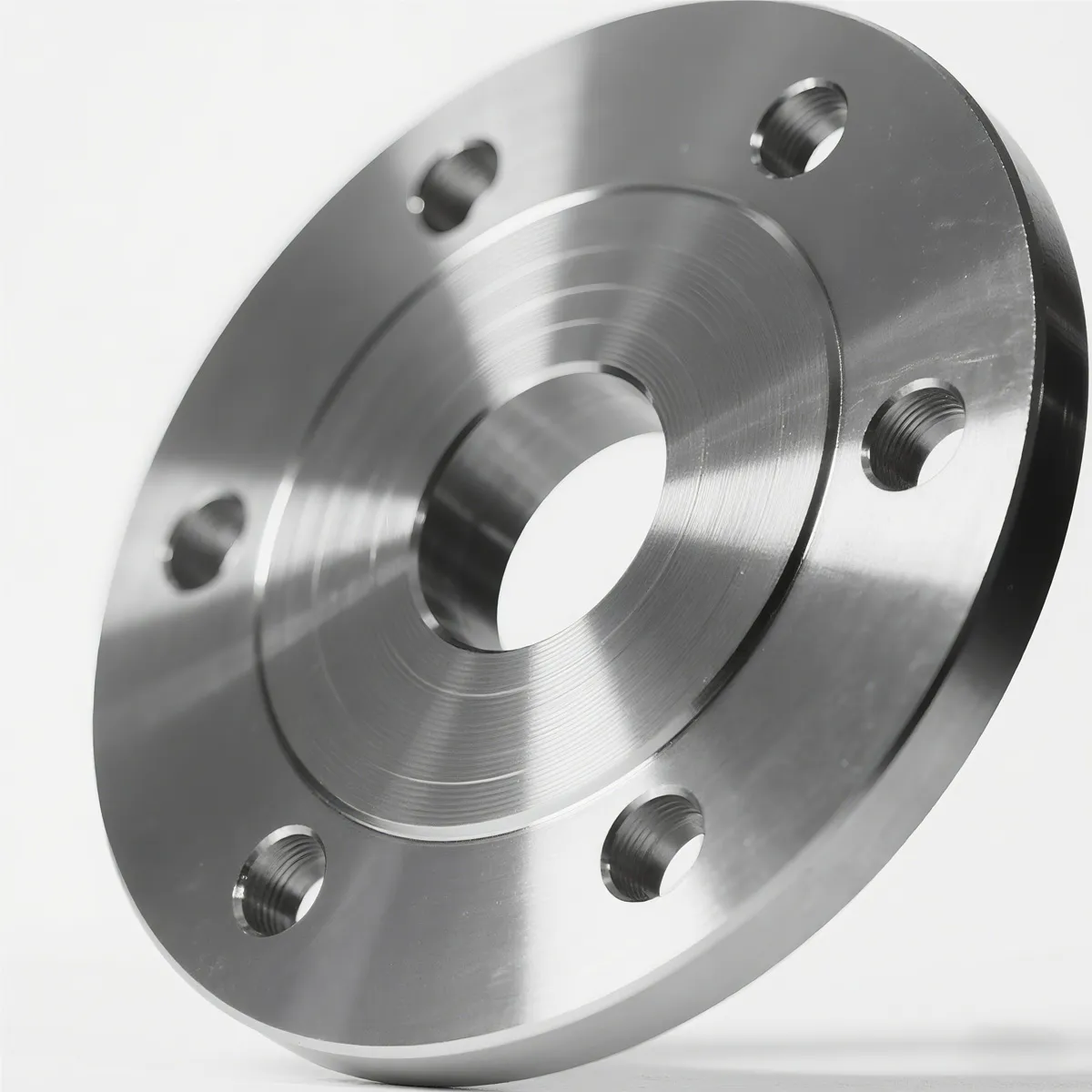

In the demanding landscape of industrial piping systems, the integrity and reliability of every component are paramount. Among the diverse array of flange types, slip on weld flanges are a cornerstone, widely recognized for their versatility, ease of installation, and cost-effectiveness in a broad range of applications. These flanges are engineered with a bore that is slightly larger than the pipe's outside diameter, enabling the pipe to be effortlessly slipped into the flange before being secured with two fillet welds—one on the inside and one on the outside. This dual-welding approach imparts substantial mechanical strength, sufficient for many medium-to-low pressure and temperature services.

The design simplicity of a slip on weld flanges facilitates a more straightforward assembly process compared to more complex flange types, significantly reducing installation time and associated labor costs. This operational efficiency is a critical advantage for projects with tight deadlines or extensive piping networks. While not typically suited for the most extreme pressure or temperature conditions where weld neck flanges might be preferred, their robust construction and reliable performance make them an indispensable component in sectors ranging from petrochemical and power generation to water treatment. They offer a balanced solution, ensuring secure, leak-proof connections vital for the safe and efficient conveyance of various industrial fluids and gases. A thorough understanding of their technical specifications, manufacturing intricacies, and application advantages is crucial for optimizing piping system design and ensuring long-term operational success.

Industry Trends in Flange Technology

The global industrial flange market is undergoing continuous evolution, driven by increasing energy demands, infrastructure development, and stringent regulatory requirements across various sectors. Projections anticipate a steady expansion, with the market expected to reach approximately USD 7.8 billion by 2029, demonstrating a Compound Annual Growth Rate (CAGR) of around 4.7% over the forecast period. This growth is significantly influenced by several key trends impacting the design, manufacturing, and application of flanges, including flange slip on welding types:

- Advanced Material Innovation: There's a persistent drive towards developing and utilizing advanced alloys, such as Duplex and Super Duplex Stainless Steels, and various Nickel-based alloys. These materials offer superior resistance to corrosion, high-temperature creep, and enhanced mechanical properties, extending the service life of flanges in increasingly aggressive operational environments.

- Digitalization and Smart Manufacturing: The adoption of Industry 4.0 principles, including Artificial Intelligence (AI), the Internet of Things (IoT), and advanced analytics, is transforming flange production. This encompasses everything from predictive maintenance for manufacturing equipment to automated quality control systems and digital twin technologies for design optimization, leading to higher precision, reduced lead times, and minimized material waste.

- Emphasis on Sustainability and Environmental Compliance: With growing global environmental concerns, manufacturers are focusing on sustainable practices. This includes optimizing material usage, improving energy efficiency in production, and designing flanges that minimize fugitive emissions, particularly crucial in sectors dealing with hazardous substances. Compliance with stringent environmental regulations is a key driver for innovation.

- Modularization and Prefabrication: A notable trend in large-scale industrial projects is the shift towards modular construction and pre-fabrication of piping spools incorporating flanges. This approach reduces on-site labor, improves safety, and accelerates project timelines, contributing to overall cost efficiencies.

- Enhanced Safety and Performance Standards: International organizations such as ASME, ISO, and API continually update their standards to reflect new technological advancements and safety requirements. This ensures that flanges meet increasingly rigorous performance benchmarks, promoting greater reliability and reducing the risk of failures in critical applications.

These trends collectively underscore an industry-wide commitment to innovation, focusing not only on the mechanical integrity of components but also on their lifecycle performance, economic viability, and environmental footprint.

Technical Specifications and Parameters

A thorough understanding of the technical specifications of slip on weld flanges is fundamental for engineers and procurement specialists to ensure optimal system design, material compatibility, and regulatory compliance. These flanges are manufactured to precise standards, dictating their dimensions, material properties, and operational limits.

- Material Grades: The choice of material is critical and depends on the fluid being transported, operating temperature, and pressure. Common specifications include ASTM A105 for carbon steel (suitable for ambient and elevated temperatures), ASTM A350 LF2 for low-temperature carbon steel (essential for cryogenic applications), and ASTM A182 F304/304L or F316/316L for stainless steel (offering superior corrosion resistance in acidic or alkaline environments). Alloy steels like ASTM A182 F5, F9, F11, F22 are used for high-temperature and high-pressure services.

- Dimensions and Pressure Ratings: Manufactured in accordance with global standards such as ASME B16.5 for pipe flanges and flanged fittings (up to NPS 24) and ASME B16.47 for large diameter steel flanges (NPS 26 through NPS 60). Pressure classes typically range from Class 150 (PN20) to Class 2500 (PN420), influencing the flange's thickness, hub dimensions, and bolting requirements. The bore of a slip-on flange is specified to be slightly larger than the pipe's outside diameter to facilitate easy pipe insertion.

- Face Types: The most common face types are Raised Face (RF) and Flat Face (FF). RF is standard and requires a raised ring on the gasket surface to concentrate bolting force over a smaller area, enhancing the seal. FF flanges are primarily used for mating with flat-face cast iron flanges or other non-metallic flanges, to prevent over-stressing. Other specialized face types, such as Ring Type Joint (RTJ), may also be available for specific high-pressure applications.

- Manufacturing Standards: Adherence to international and national standards like ASME B16.5, EN 1092-1 (European), JIS B2220 (Japanese Industrial Standards), and API 6A (American Petroleum Institute for wellhead equipment) ensures interchangeability, consistent quality, and safety performance across the industry.

- Surface Finish: The finish of the gasket contact surface is crucial for achieving a leak-tight seal. For standard RF flanges, a serrated concentric or spiral finish with a specific Roughness Average (Ra) between 125-250 microinches (3.2-6.3 µm) is common, optimized for spiral wound or metallic gaskets.

Typical Product Specification Table (ASME B16.5 Slip-On Flanges)

| Parameter | Specification/Value | Notes |

|---|---|---|

| Standard | ASME B16.5 | Pipe Flanges and Flanged Fittings |

| Nominal Pipe Size (NPS) | 1/2" - 24" (DN15 - DN600) | For larger sizes, refer to ASME B16.47 |

| Pressure Class | 150, 300, 400, 600, 900, 1500, 2500 | Operational pressure/temperature limits per ASME B16.5 |

| Common Materials | ASTM A105, A350 LF2, A182 F304/L, F316/L | Carbon Steel, LTCS, Stainless Steel |

| Face Type | Raised Face (RF), Flat Face (FF) | RF is most common; FF for special applications |

| Gasket Surface Finish | 125-250 AARH (3.2-6.3 µm Ra) | For optimal sealing with various gaskets |

| Drilling | Standard ASME bolt circle & hole quantity | Ensures compatibility with mating flanges |

These detailed specifications allow for precise engineering and procurement, ensuring that the selected flanges seamlessly integrate into the piping system while meeting all performance, safety, and regulatory requirements.

Manufacturing Process Flow

The production of high-quality slip on weld flanges is a sophisticated and multi-staged process, meticulously controlled to ensure metallurgical integrity, dimensional precision, and adherence to stringent international standards. Our manufacturing workflow integrates advanced technological capabilities with expert craftsmanship.

Detailed Manufacturing Steps:

- 1. Material Procurement and Inspection: Raw materials, typically in the form of billets or bars, are sourced exclusively from reputable, certified mills. Each batch undergoes rigorous incoming inspection, including spectrochemical analysis, to confirm that its chemical composition and mechanical properties comply with relevant ASTM, ASME, or EN standards (e.g., ASTM A105 for carbon steel, ASTM A182 for stainless and alloy steels).

- 2. Cutting: The certified raw material is precisely cut to specific lengths or weights using automated band saws or plasma cutting machines. This stage is crucial for minimizing waste and ensuring uniform starting material for subsequent forming processes.

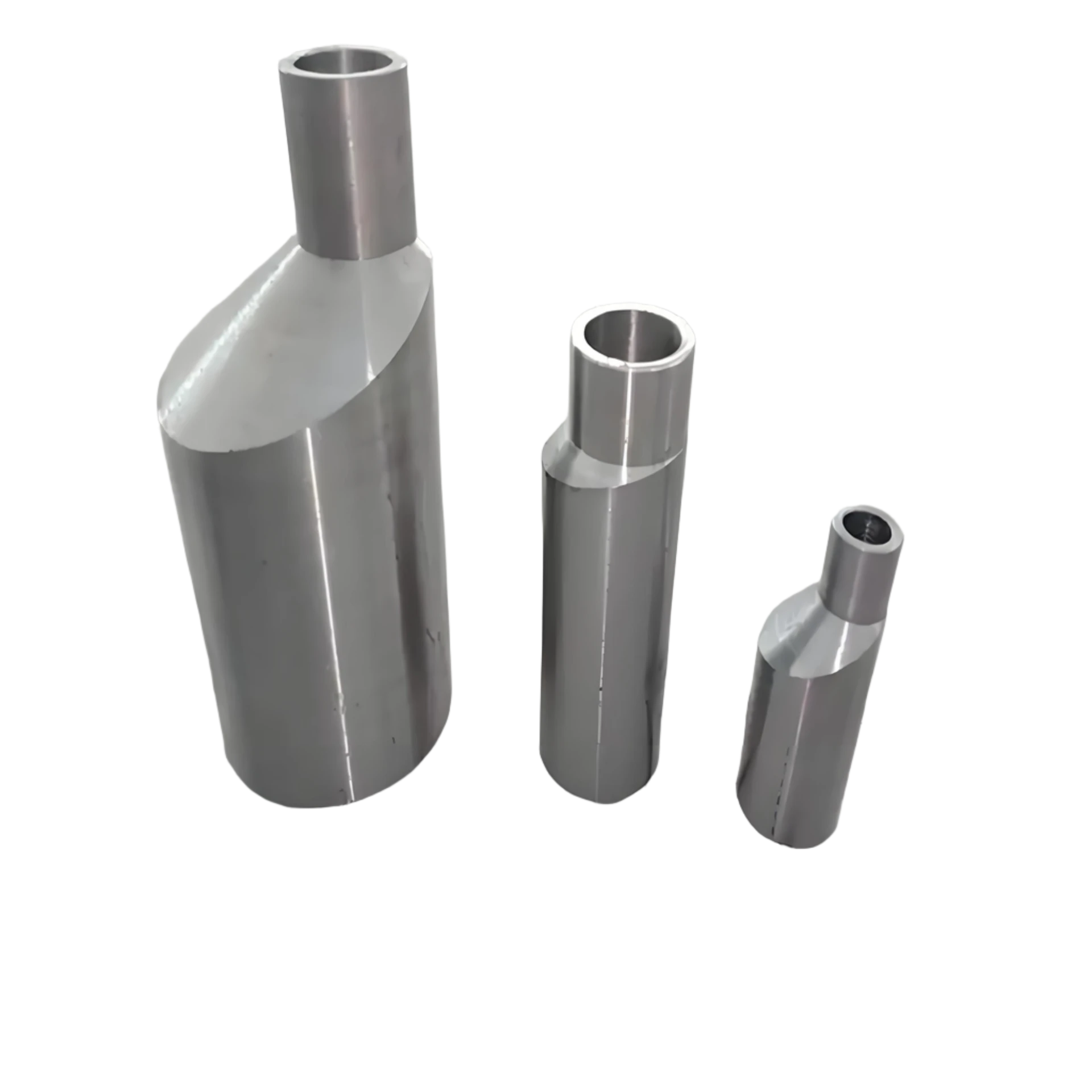

- 3. Forming (Forging): Forging is the preferred method for producing robust slip on weld flanges. Material billets are heated in induction or gas-fired furnaces to their optimal forging temperature. They are then shaped using powerful hydraulic or mechanical presses with open or closed dies. This process eliminates internal voids, refines the grain structure, and significantly enhances the material’s mechanical properties such as tensile strength, toughness, and fatigue resistance, ensuring superior performance and a longer service life compared to cast alternatives.

- 4. Heat Treatment: Post-forging, the flanges undergo various heat treatment processes, such as normalizing, annealing, or quenching and tempering. The specific treatment depends on the material grade and desired properties. Heat treatment is vital for relieving internal stresses induced during forging, homogenizing the microstructure, and achieving the required hardness and strength specifications that will allow for corrosion resistance and sustained performance in target industries like petrochemical or water supply & drainage.

- 5. CNC Machining: Precision Computer Numerical Control (CNC) machining is then employed to achieve the final dimensions, including the bore diameter (slightly larger than pipe OD), outside diameter, hub thickness, face type (Raised Face, Flat Face), and precise bolt hole patterns. Modern CNC machines ensure exceptional dimensional accuracy and superior surface finishes, which are critical for proper gasket sealing and overall structural integrity.

- 6. Drilling: Bolt holes are accurately drilled according to ASME B16.5 or other specified standards using high-precision drilling equipment, often multi-spindle machines for efficiency and consistency.

- 7. Surface Finishing: The flange surfaces are prepared, often by shot blasting, to remove scale and provide a clean finish. The gasket contact surfaces receive specialized finishes, typically serrated, to achieve specific Roughness Average (Ra) values that optimize sealing performance and prevent leaks.

-

8. Non-Destructive Testing (NDT) & Quality Control: Each flange undergoes rigorous quality inspections:

- Dimensional Inspection: Every critical dimension is verified against engineering drawings and standards.

- Visual Inspection: Thorough examination for surface defects, cracks, and imperfections.

- Ultrasonic Testing (UT) & Magnetic Particle Inspection (MPI): Forgings are often subjected to UT to detect internal flaws, and MPI (for ferrous materials) to identify surface-breaking defects, particularly for critical applications.

- Mechanical Properties Testing: Samples from the heat lot undergo tensile strength, yield strength, elongation, and hardness tests to confirm mechanical integrity.

- Hydrostatic Testing: While flanges themselves are not hydrostatically tested, the material and design are qualified to withstand specified pressure ratings per ISO/ANSI standards.

- 9. Marking and Packaging: Conforming flanges are permanently marked with essential information including material grade, pressure class, nominal pipe size, manufacturer's name or logo, and heat number for full traceability. They are then treated with rust-preventative coatings or oils, fitted with protective caps, and securely packaged to prevent damage during transit.

This exhaustive manufacturing and quality assurance process ensures that every flange slip on welding component delivered to our clients performs reliably under the most demanding conditions, boasting a typical service life exceeding 25-30 years when properly installed and maintained.

Application Scenarios and Target Industries

Slip on weld flanges are integral to a vast array of industrial piping systems, valued for their adaptability and proven performance in numerous applications. Their design characteristics—particularly the ease of pipe insertion and dual fillet welding—make them suitable for specific operational contexts where efficiency and cost-effectiveness are crucial.

Key Target Industries:

- Petrochemical and Chemical Processing: Extensively utilized in refineries, chemical plants, and processing units for lines carrying various hydrocarbons, chemicals, and refined products. Their material flexibility allows for customization to resist a wide range of corrosive media.

- Oil and Gas Sector: Found in midstream and downstream operations, including pipelines, storage tanks, and processing facilities. While high-pressure transmission lines often favor slip on weld neck flange designs, slip-on variants are prevalent in utility lines, auxiliary services, and systems requiring easier modifications or repairs.

- Power Generation: Employed in both fossil fuel and renewable energy power plants for water treatment, steam distribution (especially low-pressure lines), and cooling systems. Their ease of installation is beneficial in complex plant layouts.

- Water Supply & Drainage Systems: Critical components in municipal water treatment plants, industrial water distribution networks, and wastewater management facilities, providing reliable and leak-tight connections for large diameter piping.

- Mining and Metallurgy: Used in mineral processing plants for slurry transport, water supply, and chemical reagent lines, requiring robust construction and, often, specialized materials for abrasive or corrosive conditions.

- Shipbuilding and Marine Applications: Applied in various onboard piping systems for cooling water, ballast, and fuel lines, where their relatively compact design and ease of assembly are advantageous in confined spaces.

Typical Application Scenarios and Advantages:

- Process Piping for Non-Critical Services: For general service lines conveying non-hazardous fluids at moderate pressures and temperatures, slip-on flanges offer a robust yet economical connection. This includes cooling water loops, air systems, and drain lines, where their ease of installation translates to significant labor savings.

- System Modifications and Maintenance: In existing plants requiring frequent modifications or pipe reroutes, the adaptability of these flanges allows for quicker cut-and-weld operations, minimizing downtime and supporting continuous operational efficiency.

- Corrosion Resistance in Chemical Handling: When fabricated from appropriate stainless steel or alloy steel grades, slip on weld flanges provide excellent corrosion resistance against a broad spectrum of aggressive chemicals, crucial for preventing leaks, environmental contamination, and ensuring energy saving by maintaining system integrity.

- Large Diameter Water/Effluent Lines: In large-scale water or wastewater projects, the ability to accommodate minor misalignments during pipe fit-up makes slip-on flanges a practical choice, reducing the need for costly and time-consuming rework on site.

The proven reliability and operational advantages of these flanges underscore their continuous role as a preferred solution for engineers seeking efficient and secure piping connections across various critical industries.

Technical Advantages of Slip-On Weld Flanges

The widespread adoption of slip on weld flanges in industrial piping systems is attributable to several inherent technical advantages, particularly in scenarios where ease of installation, cost-effectiveness, and adequate mechanical strength are primary considerations.

- Simplified Alignment and Installation: One of the most significant advantages is the ease with which the pipe can be slipped into the flange before welding. This allows installers considerable freedom to adjust the pipe for optimal alignment with the mating flange or equipment nozzles, reducing the need for precise pipe cutting and fit-up typically required for butt-welded connections. This flexibility substantially cuts down on installation time and labor costs.

- Cost-Effectiveness in Fabrication: Generally, slip-on flanges are more economical to manufacture than weld neck flanges. Their design requires less complex forging and less intensive machining, translating into lower unit costs. While they require two fillet welds (inside and outside) during installation, these welds are often simpler and quicker to execute than a full penetration butt weld, further contributing to overall project cost savings.

- Adaptability to Various Pressure Classes: Although commonly specified for Class 150 to Class 600 applications, these flanges are available in pressure ratings up to Class 2500. This wide range of available pressure classes makes them highly versatile, suitable for a broad spectrum of low to medium-pressure industrial services. The robustness provided by the dual fillet welds ensures reliable performance within these specified limits.

- Good Fatigue Resistance: When properly installed with two well-executed fillet welds (one on the inner bore and one on the outer face), slip-on flanges provide good resistance to cyclic stresses and vibrations. The dual-weld configuration distributes stress effectively, making them a durable choice for many applications, although weld neck flanges typically offer superior fatigue performance in extremely severe conditions.

- Reduced Space Requirements (Compared to Weld Neck): The relatively compact design of a slip-on flange, lacking the extended hub of a slip on weld neck flange, can be advantageous in installations where space is at a premium, such as crowded pipe racks or compact equipment layouts.

- Ease of Modularity and System Modification: For piping systems that may undergo future modifications, expansions, or repairs, the ability to more easily cut out and re-weld slip-on flanges provides a practical benefit, simplifying maintenance procedures and reducing associated downtime.

These distinctive technical attributes highlight why slip on weld flanges continue to be a preferred component for engineers and project managers seeking an optimal balance of performance, installation efficiency, and cost control in their industrial piping projects.

Vendor Comparison and Selection Criteria

Choosing the right vendor for critical components such as slip on weld flanges is a strategic decision that extends beyond mere cost. For B2B decision-makers and engineers, a comprehensive evaluation of potential suppliers based on a robust set of criteria is essential to ensure product quality, project success, and long-term operational integrity.

Key Factors for Vendor Evaluation:

- 1. Quality Certifications and Compliance: A reputable vendor must demonstrate adherence to international quality management systems (e.g., ISO 9001:2015) and product-specific standards (e.g., ASME B16.5, EN 1092-1, JIS B2220, API specifications). Certifications like CE marking (for European markets) and a strong track record of compliance are non-negotiable indicators of product reliability and consistency.

- 2. Material Traceability and Documentation: Demand full material traceability, including Mill Test Certificates (MTCs or 3.1 certificates) for all supplied flanges. These documents verify the chemical composition and mechanical properties of the raw material, ensuring compliance with specifications and providing accountability.

- 3. Manufacturing Capabilities and Technology: Assess the vendor's production facilities. This includes the use of advanced forging techniques, state-of-the-art CNC machining centers, and comprehensive in-house Non-Destructive Testing (NDT) capabilities. Vendors with the ability to handle a wide range of materials, sizes (including large diameter flanges), and pressure classes often possess superior technical expertise.

- 4. Experience and Industry Reputation: Prioritize vendors with a proven track record of successfully supplying flanges to your specific industry (e.g., petrochemical, power generation). Years of experience, positive client testimonials, and reference projects underscore a vendor's reliability and deep understanding of industry-specific challenges.

- 5. Customization Capabilities: For projects with unique requirements (e.g., exotic materials, non-standard dimensions, specific surface finishes, or specialized coatings), a vendor's ability to provide tailored engineering and manufacturing solutions is a significant advantage.

- 6. Lead Times and Supply Chain Robustness: Evaluate the vendor's capacity to meet your project timelines. A strong supply chain, efficient inventory management, and transparent communication regarding lead times are crucial for project planning and execution. Look for vendors with a global logistics network if international delivery is required.

- 7. After-Sales Support and Warranty: Comprehensive technical support, clear warranty commitments, and responsive customer service are vital for addressing any issues that may arise post-purchase, ensuring ongoing operational efficiency and minimizing potential downtime.

Flange Type Comparison: Slip-On vs. Weld Neck

| Feature | Slip-On Weld Flange | Weld Neck Flange |

|---|---|---|

| Modus Connexionis | Two fillet welds (inside and outside) | Single full penetration butt weld |

| Pressure & Temperature Suitability | Moderate (Class 150-600 preferred) | High (Class 150-2500+), Critical Services |

| Fatigue Resistance | Good (with proper welding) | Excellent (Hub design, butt weld provides superior stress distribution) |

| Installation Ease | High (Easy pipe alignment) | Moderate (Requires precise pipe alignment for butt weld) |

| Cost (Flange & Welding) | Lower flange cost, higher welding labor cost | Higher flange cost, lower welding labor cost (single weld) |

| Radiography Requirement | Not typically required for fillet welds | Often required for butt welds (full penetration) |

By diligently evaluating these factors, companies can forge reliable partnerships with suppliers who not only provide high-quality components but also contribute significantly to the overall success and longevity of their industrial operations.

Customized Solutions for Specific Needs

While standard slip on weld flanges are designed to meet a wide array of industrial applications, complex projects often encounter unique challenges that demand tailored engineering solutions. Leading manufacturers recognize this need and offer extensive customization capabilities to address specific operational parameters, material constraints, and unique design requirements.

Areas of Customization Offered:

- Exotic Material Grades: Beyond common carbon and stainless steels, customization can extend to highly specialized alloys. This includes Duplex and Super Duplex Stainless Steels (e.g., UNS S31803, S32750) for superior corrosion and stress cracking resistance, Nickel Alloys (e.g., Inconel, Monel, Hastelloy) for extreme temperatures and aggressive chemical environments, and even Titanium for applications requiring exceptional strength-to-weight ratio and resistance to specific media.

- Non-Standard Dimensions: Projects may require flanges with dimensions that deviate from standard ASME or EN tables. This could involve custom bore diameters to match non-standard pipe schedules, unique outside diameters, specific bolt circle patterns for mating with proprietary equipment, or increased flange thickness for enhanced structural integrity in certain applications.

- Special Face Finishes: While Raised Face (RF) and Flat Face (FF) are standard, custom face finishes like Ring Type Joint (RTJ) for high-pressure, high-temperature applications requiring a metal-to-metal seal, or tongue-and-groove and male-and-female faces for specific gasket types can be engineered to optimize sealing performance.

- Surface Coatings and Linings: To combat severe corrosion, erosion, or fouling, flanges can be supplied with advanced internal or external coatings. Examples include specialized anti-corrosion paints, epoxy coatings, hot-dip galvanization, or even internal linings of rubber, PTFE, or glass for protection against highly aggressive chemical attacks or abrasive slurries.

- Specific Drilling and Tapping: Custom bolt hole patterns, non-standard thread types (e.g., fine pitch threads), or specific tapping depths for stud bolts can be accommodated to meet unique assembly requirements or to interface with existing infrastructure.

- Higher Pressure or Temperature Capabilities: For applications pushing the upper limits of standard slip-on flange ratings, custom designs can be engineered with modified material compositions, increased wall thicknesses, or enhanced hub configurations to safely handle higher pressures or elevated temperatures, after thorough engineering analysis and stress calculations.

Collaborating with a manufacturer possessing strong engineering design capabilities for customized solutions ensures that even the most intricate piping system challenges are met with precision-engineered flange slip on welding products, delivering optimal performance, reliability, and compliance for the project's unique demands. This adaptability is crucial for innovation and problem-solving in modern industrial environments.

Application Case Studies

The practical advantages and proven reliability of slip on weld flanges are best demonstrated through their successful deployment in real-world industrial projects. These case studies highlight how their specific attributes contribute to efficient, robust, and cost-effective piping solutions.

Case Study 1: Large-Scale Petrochemical Plant Expansion – Utility Lines

A major petrochemical company embarked on a multi-billion-dollar expansion project, requiring an extensive network of utility piping for cooling water, nitrogen, and low-pressure steam (NPS 10" to 36", Class 150/300). Given the sheer volume of connections and the tight construction schedule, the project engineers specified A105 Carbon Steel slip on weld flanges with Raised Faces. The contractor reported a significant reduction in overall installation time, estimated at 20% compared to using weld neck flanges, primarily due to the simpler pipe-to-flange alignment and faster dual fillet welding process. This efficiency directly contributed to the project being completed ahead of schedule and within budget, ensuring the plant's rapid commissioning and sustained operational uptime.

Case Study 2: Pulp and Paper Mill Upgrade – Chemical Recovery Lines

A pulp and paper mill in North America initiated an upgrade to its chemical recovery boiler system, which involved handling corrosive black liquor at moderate pressures and elevated temperatures. For the secondary recovery lines (NPS 8" to 20", Class 300), 316L Stainless Steel slip on weld flanges were selected for their superior corrosion resistance against the aggressive chemical media. The slip-on design allowed for easier field fabrication and alignment, which was particularly beneficial given the complex routing through existing plant infrastructure. The robust dual fillet welds provided the necessary structural integrity, ensuring long-term leak prevention and significantly reducing maintenance intervals related to flange connections, thus improving overall operational safety and efficiency.

Case Study 3: Data Center Cooling Infrastructure – Chilled Water Lines

A new hyperscale data center required a highly efficient and reliable chilled water cooling infrastructure (NPS 6" to 24", Class 150). The primary concerns were fast installation to meet aggressive build timelines and assurance of leak-free operation to protect sensitive electronic equipment. ASTM A105 Carbon Steel slip on weld flanges were chosen for their balance of cost-effectiveness and ease of assembly. The ability to slip the pipe into the flange and make positional adjustments before welding streamlined the installation process across thousands of connection points. Post-commissioning inspections confirmed the integrity of all connections, demonstrating the suitability of these flanges for critical non-hazardous utility applications where precision and speed are paramount, contributing to significant energy saving in the data center's operational cooling.

These varied examples underscore the versatility and reliability of slip on weld flanges across different industrial sectors, consistently contributing to enhanced project efficiency, cost optimization, and dependable long-term performance.

Frequently Asked Questions (FAQ)

Q1: What are the primary advantages of using slip on weld flanges over other flange types?

The main advantages of slip on weld flanges include ease of installation due to simple pipe alignment, lower initial material cost compared to weld neck flanges, and suitability for a wide range of low to medium-pressure and temperature applications. Their dual fillet welding process provides robust, leak-tight connections for many industrial services.

Q2: What materials are commonly available for slip on weld flanges?

Noster slip on weld flanges are commonly manufactured from high-grade Carbon Steel (e.g., ASTM A105, A350 LF2), Stainless Steel (e.g., ASTM A182 F304/304L, F316/316L), and various Alloy Steels (e.g., ASTM A182 F11, F22). Material selection is always guided by the specific application's pressure, temperature, corrosion resistance, and fluid compatibility requirements to ensure optimal performance and longevity.

Q3: What are your typical lead times for custom or large orders, and what are your warranty commitments?

Lead times for our flanges vary based on material availability, order volume, and customization complexity. For standard products, lead times typically range from 2 to 6 weeks. Custom or large orders may require 8 to 14 weeks. We offer a standard warranty of 12 months from installation or 18 months from shipment, whichever comes first, against manufacturing defects. Detailed warranty terms are provided with each quotation and purchase agreement.

Q4: What kind of customer support and after-sales service do you provide?

We are committed to comprehensive customer support. Our dedicated technical team provides expert guidance on product selection, installation, and maintenance. We offer responsive after-sales support for any operational queries or troubleshooting needs, ensuring minimal downtime and maximizing the performance of our flange slip on welding products throughout their service life. Your satisfaction and the continuous, safe operation of your systems are our top priorities.

References

- ASME B16.5, Pipe Flanges and Flanged Fittings: NPS 1/2 Through NPS 24 Metric/Inch Standard. American Society of Mechanical Engineers.

- ASTM A105/A105M, Standard Specification for Carbon Steel Forgings for Piping Applications. ASTM International.

- ASTM A182/A182M, Standard Specification for Forged or Rolled Alloy and Stainless Steel Pipe Flanges, Forged Fittings, and Valves and Parts for High-Temperature Service. ASTM International.

- ISO 9001:2015, Quality management systems – Requirements. International Organization for Standardization.

- API Specification 6A, Specification for Wellhead and Christmas Tree Equipment. American Petroleum Institute.

-

Aug. 22, 2025

Aug. 22, 2025HEBEI JIUYUAN PIPELINE MANUFACTURING CO.,LTD. is located in Mengcun Hui Autonomous County, known as

-

XXIV Aprilis, MMXXXV

XXIV Aprilis, MMXXXVJiuyuan Pipeline is excited to announce its participation in the upcoming 2025 Wire / Tube with Metal & Steel KSA exhibition, scheduled from May 5th to May 7th, 2025.

Si nostris productis interes, informationes tuas hic relinquere potes, et mox tecum communicabimus.