In the pipeline fitting wholesale sector, HEBEI JIUYUAN PIPELINE MANUFACTURING CO.,LTD. stands out for supplying top-quality каўпачкі для труб, including tube end caps and pipe end cap. Based in Mengcun Hui Autonomous County, the "Capital of Elbows", our company is equipped with advanced production facilities, strong technical capabilities and strict testing equipment. With a registered capital of 10.09 million yuan, we’ve earned a top industry ranking thanks to excellent quality and service. Having passed ISO9001:2008 quality system certification and pressure pipeline special equipment certification, we stay committed to technological innovation and product quality enhancement. These каўпачкі для труб are vital for safeguarding piping system safety and efficiency, and we fully grasp their significance across diverse industrial sectors.

Types and Specifications of Pipe Caps---H2

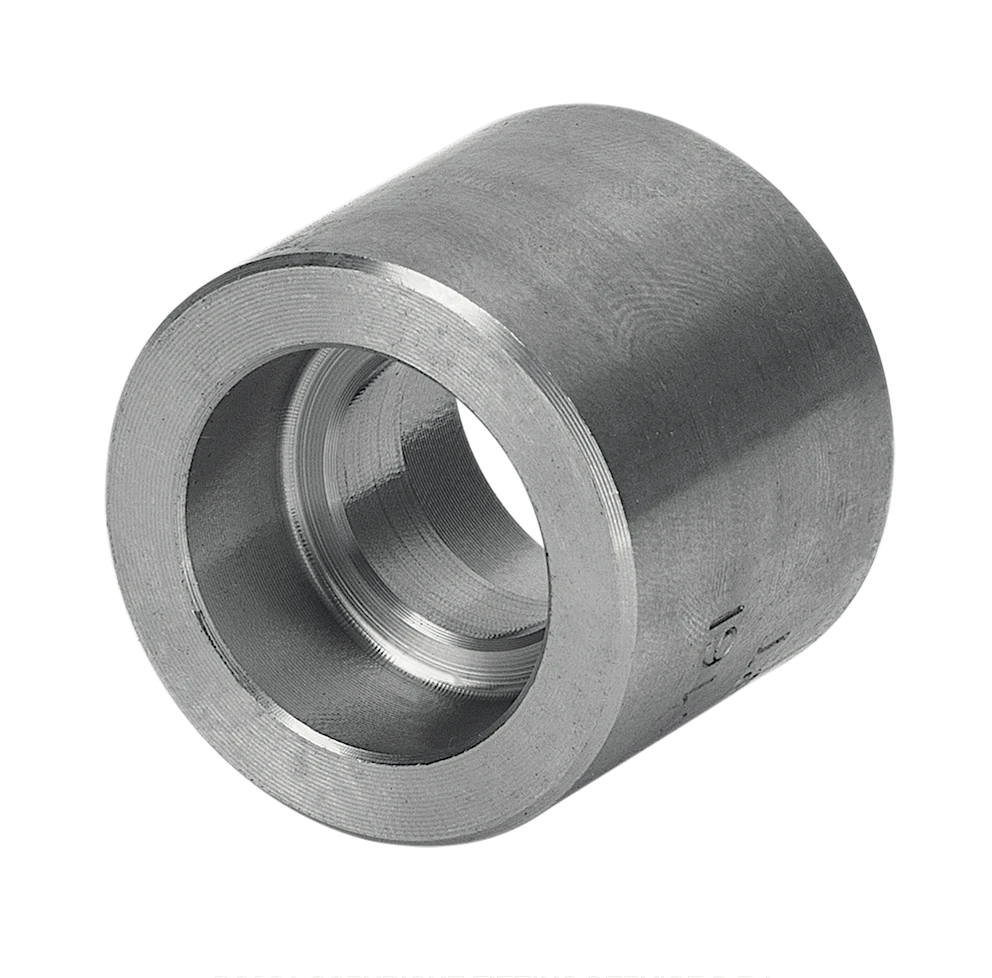

- Pipe caps include tube end caps and pipe end cap, designed to seal different pipe ends with secure, leak-proof closures.

- Pipe capsuse materials like carbon steel and stainless steel, selected to perform well in high-pressure, high-temperature or corrosive environments.

- Pipe caps comply with international standards such as GB and ANSI/ASME, ensuring compatibility with global piping systems.

- Pipe caps offer surface coatings like galvanize and epoxy paint to enhance corrosion resistance and durability.

|

Aspect

|

Details

|

|

Types

|

Pipe end cap, Tube end caps

|

|

Size Range

|

15/ ½Inch - 900/ 36Inch

|

|

Materials (MAR)

|

CS (ASTM A105, P235GH, etc.); SS (ASTM A182, 304, etc.)

|

|

Standards

|

GB, ANSI/ASME, JIS, DIN

|

|

Surface Coating

|

Black paint, Galvanize, Grease, Epoxy paint

|

Product Features of Pipe Caps---H2

- Pipe caps, including tube end caps and pipe end cap, have thicker walls than standard fittings, providing high strength and smooth connections.

- Pipe caps have beveled ends that create leak-resistant welds when flush with pipes, ensuring tight seals and system safety.

- Made of corrosion-resistant materials, каўпачкі для труб perform well under high pressure and temperature, blocking contaminants effectively.

- Pipe caps come in various sizes and connection types, with easy installation and maintenance for compatibility with different systems.

Industrial Applications of Pipe Caps---H2

- Oil and gas industry uses каўпачкі для труб; pipe end cap and tube end caps prevent contaminants and assist in pressure testing.

- Chemical processing plants rely on каўпачкі для труб to seal ends, preventing chemical leaks and ensuring production safety.

- Water treatment facilities use каўпачкі для труб to protect pipe ends, with tube end caps in auxiliary pipelines to maintain water quality.

- Construction and plumbing use каўпачкі для труб to protect open ends during installation or transportation, and for future expansion needs.

Pipe Caps Cost Effective Safety Solutions---H2

- Pipe caps prevent contamination and leaks, reducing expensive repairs and maintenance to save long-term costs.

- Durable каўпачкі для труб have a long service life, reducing replacement frequency and overall costs compared to other methods.

- Easy installation of каўпачкі для труб saves time and labor, with simple maintenance enhancing cost-effectiveness.

- Pipe caps ensure system safety and efficiency, avoiding production shutdowns and reducing economic losses.

Pipe Caps FAQS---H2

What are the main types of pipe caps?---H3

The main types of каўпачкі для труб are pipe end cap and tube end caps. They are designed to seal different pipe ends, with various sizes and connection types like threaded, welded and flanged, meeting different system and application needs.

What materials are pipe caps made of?---H3

Наш каўпачкі для труб are made of carbon steel and stainless steel. Carbon steel offers high strength, while stainless steel provides corrosion resistance. Both pipe end cap and tube end caps use these materials to adapt to different environments.

What are the features of pipe caps?---H3

Pipe caps have thicker walls for strength, beveled ends for leak-resistant welds, and corrosion resistance to withstand harsh conditions. They come in various sizes and connection types, with easy installation and maintenance, and can block contaminants.

In which industries are pipe caps commonly used?---H3

Pipe caps are used in oil and gas, chemical processing, water treatment, construction and plumbing. They play roles like preventing contaminants, assisting in testing, and protecting pipe ends in these industries.

Why are pipe caps cost effective safety solutions?---H3

Pipe caps are cost-effective as they prevent leaks and contamination, reducing repair costs. Their durability cuts replacements, easy installation saves labor, and they avoid shutdowns, reducing economic losses while ensuring safety.

We are committed to providing high-quality каўпачкі для труб, tube end caps and pipe end cap products. If you want to know more about our products or have any specific requirements, welcome to visit our company.