In the pipeline fitting wholesale industry, HEBEI JIUYUAN PIPELINE MANUFACTURING CO.,LTD. is a reliable provider of high-quality flange products, including socket flange. Located in Mengcun Hui Autonomous County, known as the "Capital of Elbows", our company has advanced production facilities, strong technical capabilities and strict testing equipment. With a registered capital of 10.09 million yuan, we have ranked among the top in the industry due to our excellent quality and service. Having passed the ISO9001:2008 quality system certification and the special equipment certification for pressure pipelines, we are committed to technological innovation and product quality improvement. This flange product plays a key role in high-temperature pipeline systems, and we know its industrial value well.

Socket Flange Varieties and Specifications---H2

- Socket flange is designed for small-diameter piping, meeting high-pressure connection needs with precise dimensions.

- It uses carbon steel and stainless steel, adapting to diverse working conditions with stable material performance.

- It follows global standards like ASME, ensuring compatibility with international pipeline systems.

- It offers surface coatings to enhance corrosion resistance, extending its service life.

|

Aspect

|

Details

|

|

Types

|

Socket weld flange

|

|

PN/CLASS

|

PN6 - PN40/ Class150 - Class2500

|

|

DN/INCH

|

Dn10 - DN2000/ ½In - 24In/S.A 12In - 60In

|

|

Materials (MAR)

|

CS (ASTM A105, P235GH, etc.); SS (ASTM A182, 304, etc.)

|

|

STD

|

ASME, EN, JIS, DIN, BS, KS, GOST, SABS, ATK

|

|

Surface Coating

|

Black paint, Galvanize, Grease, Epoxy paint

|

Socket Weld Flange Key Characteristics---H2

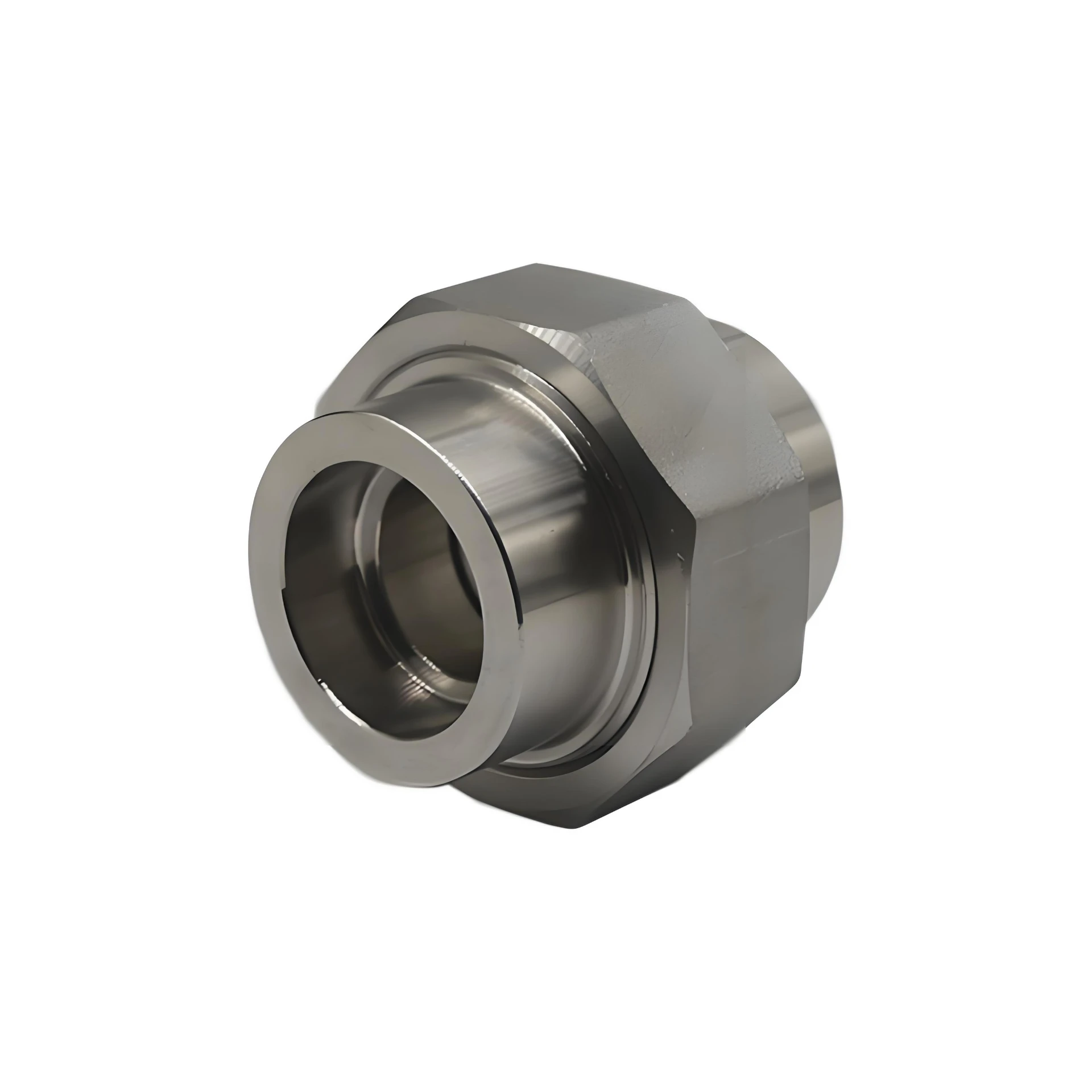

- Socket weld flange has a recessed socket, allowing smooth pipe insertion and reducing flow resistance.

- It features an internal stop, supporting pipes during installation to prevent slipping.

- It boasts strong mechanical strength, withstanding high pressure without deformation.

- It enables easy alignment, ensuring tight connections that outperform threaded joints in some cases.

Socket Weld Flange Practical Uses---H2

- Socket weld flange is used in oil and gas small-diameter pipelines, ensuring secure oil and gas transport.

- It fits chemical processing, safely conveying corrosive media with its leak-proof design.

- It works in power generation steam lines, enduring high temperatures for stable operation.

- It aids water treatment high-pressure piping, supporting efficient water processing.

Socket Flange High Temperature Performance---H2

- Socket flange uses heat-resistant materials, maintaining stability under high temperatures to avoid connection failure.

- It has a design that enhances joint heat resistance, preventing cracks in high-temperature environments.

- It resists thermal expansion, reducing leakage risks even when temperatures fluctuate.

- It resists high-temperature corrosion, withstanding media erosion for long-term use.

Socket Flange FAQS---H2

What makes socket weld flange suitable for high temperatures?---H3

Socket weld flange is suitable for high temperatures due to its heat-resistant materials and structural design. The materials used can maintain their mechanical properties even at elevated temperatures, while the flange’s structure ensures that the joint remains stable, avoiding deformation or leakage that could occur in less robust fittings.

How does socket flange differ from other flange types?---H3

Socket flange differs from other flanges in its design: it has a recessed socket for pipe insertion, which simplifies alignment and creates a smoother flow path. Unlike some flanges that rely on bolts for sealing, its connection is enhanced by welding, making it more suitable for small-diameter, high-pressure systems.

What should be noted during socket flange welding?---H3

During socket flange welding, it’s important to ensure the pipe is properly inserted into the socket and positioned against the internal stop to prevent slipping. Welding should be done evenly to form a tight seal, and post-weld inspection is necessary to check for cracks or defects that could affect performance, especially in high-temperature applications.

Can socket flange handle both high pressure and high temperature?---H3

Yes, socket flange can handle both high pressure and high temperature. Its durable materials and strong structure allow it to withstand the combined stresses of pressure and heat, making it a reliable choice for systems like steam lines in power plants where both factors are present.

What maintenance does socket flange require in high-temperature settings?---H3

In high-temperature settings, socket flange requires regular inspections to check for signs of heat-induced wear, such as corrosion or loosening. Cleaning the flange surface to remove high-temperature deposits and ensuring the joint remains intact are also important to maintain its performance and extend its service life.

We are committed to providing high-quality socket flange and אוגן ריתוך שקע products. If you want to know more about our products or have any specific requirements, welcome to visit our company.