- Albanian

- Arabic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bulgarian

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Finnish

- French

- German

- Greek

- Hebrew

- Hungarian

- Indonesian

- irish

- Italian

- Japanese

- Khmer

- Korean

- Kyrgyz

- Lao

- Latin

- Lithuanian

- Malay

- Myanmar

- Norwegian

- Persian

- Polish

- Portuguese

- Romanian

- Russian

- Serbian

- Slovak

- Slovenian

- Spanish

- Swedish

- Tagalog

- Thai

- Turkish

- Turkmen

- Uzbek

- Vietnamese

- Zulu

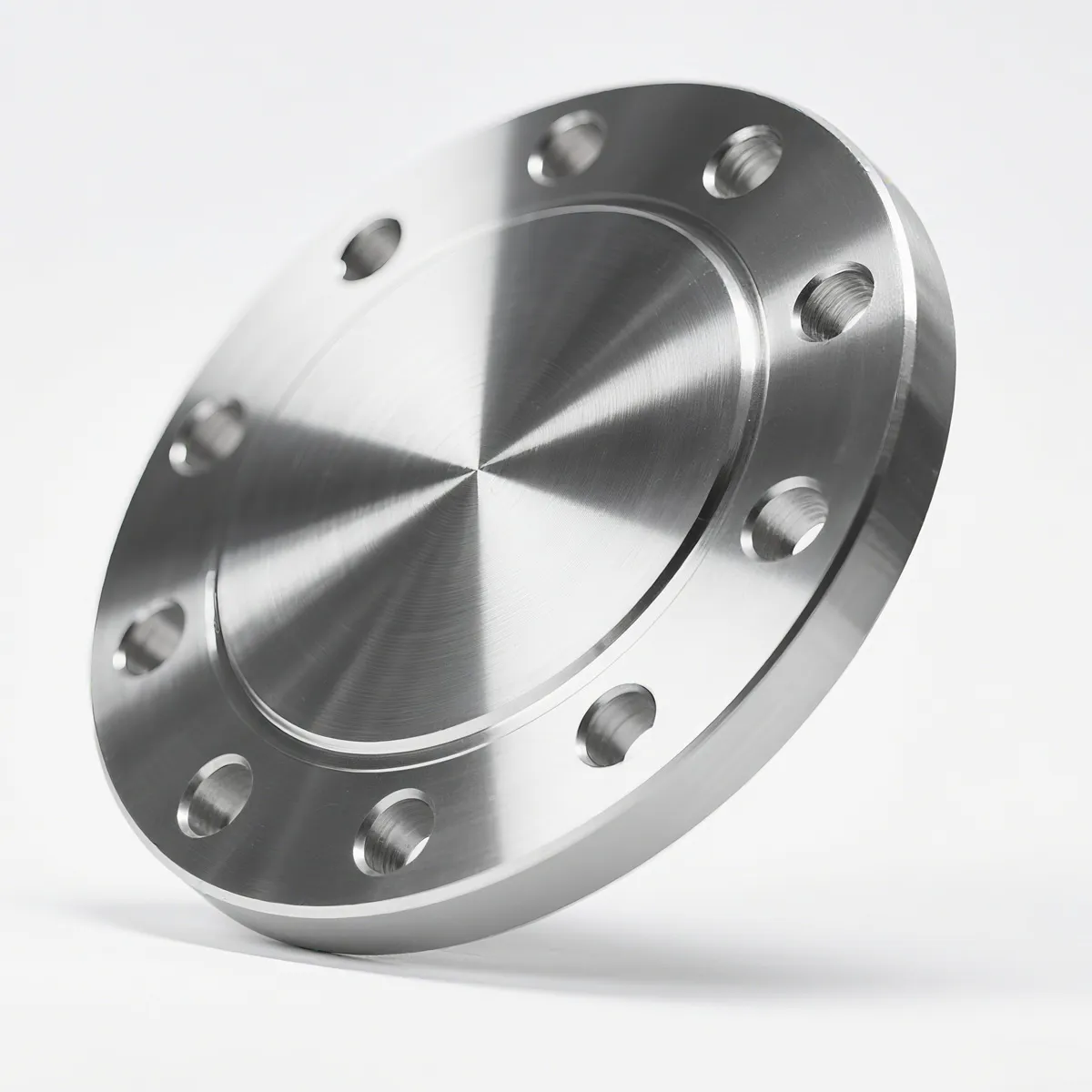

Blind flanges are essential components in industrial piping systems, designed to block off pipelines, valves, or pressure vessels. Their versatility, durability, and compliance with international standards make them indispensable in industries such as oil and gas, petrochemicals, and power generation. This article provides an in-depth analysis of blind flanges, their technical specifications, applications, and the role of NIST (National Institute of Standards and Technology) in advancing industrial standards.

Understanding Blind Flanges: What Are They?

A blind flange is a solid disk used to seal the end of a piping system, valve, or pressure vessel. Unlike other flanges, it lacks a central hole, making it ideal for stopping the flow of fluids or gases. These flanges are commonly used during system shutdowns, pressure testing, or when future expansion or maintenance is required.

Manufactured from materials such as carbon steel, stainless steel, and alloy steel, blind flanges are engineered to withstand high pressure and temperature conditions. They are available in a wide range of pressure ratings, including ANSI/ASME, DIN, JIS, and others, ensuring compatibility with international standards. The blind flange types include flat-face, raised-face, and ring-type joint designs, each suited for specific applications.

Key Features of Blind Flanges

Blind flanges are designed for ease of installation and removal, making them ideal for systems requiring frequent inspection or maintenance. Their solid construction provides a secure, leak-proof seal, ensuring the integrity of piping systems. Key features include:

- Material Variety: Available in carbon steel (ASTM A105, P235GH), stainless steel (ASTM A182, 304/306), and alloy steel for specialized applications.

- Pressure Ratings: PN6 to PN40 (Class 150 to Class 2500), accommodating both low- and high-pressure environments.

- Size Range: DN10 to DN2000 (½ inch to 24 inches), with options for S.A 12 inch to 60 inch in some configurations.

- Surface Coatings: Black paint, galvanization, grease, or epoxy paint for corrosion resistance and durability.

Advantages of Using Blind Flanges

Blind flanges offer several advantages that make them a preferred choice in industrial applications:

- Easy Installation and Removal: Bolted connections allow for quick access to pipelines without permanent modifications.

- Cost-Effective: Eliminate the need for permanent closures, reducing long-term maintenance costs.

- Compliance with Standards: Adherence to ASME, EN, JIS, DIN, and other global standards ensures interoperability.

- Enhanced Safety: Secure sealing minimizes risks of leaks, which is critical in high-pressure or hazardous environments.

Technical Specifications of Blind Flanges

| Parameter | Details |

|---|---|

| Pressure/Class | PN6 - PN40 / Class 150 - Class 2500 |

| Diameter (DN/Inch) | DN10 - DN2000 / ½ In - 24 In / S.A 12 In - 60 In |

| Materials | Carbon Steel (ASTM A105, P235GH, P245GH, P250GH, P265GH, ST37-2), Stainless Steel (ASTM A182, 304, 306) |

| Standards | ASME, EN, JIS, DIN, BS, KS, GOST, SABS, ATK |

| Surface Coating | Black paint, Galvanize, Grease, Epoxy paint |

| Application | Sealing pipelines, valves, and pressure vessels in low-pressure, noncorrosive environments |

Applications of Blind Flanges

Blind flanges are widely used across industries due to their reliability and adaptability. Key applications include:

- Oil and Gas: Sealing pipelines during maintenance or expansion projects.

- Petrochemical: Blocking valves and vessels for safe chemical processing.

- Power Generation: Ensuring leak-proof connections in steam and water systems.

- Water Treatment: Controlling flow in municipal and industrial water systems.

- Shipbuilding: Providing accessible closures in marine piping networks.

Installation Process of Blind Flanges

Proper installation of a blind flange is critical to ensuring a secure seal. The steps include:

- Preparation: Clean flange faces and gaskets to remove debris.

- Gasket Selection: Choose a gasket compatible with the fluid and pressure in the system.

- Bolt Alignment: Match bolt holes and insert bolts, ensuring correct grade and quantity.

- Torque Application: Use a torque wrench to tighten bolts in a crisscross pattern for even pressure.

- Pressure Testing: Verify the seal for leaks after installation.

Installation is typically performed during system shutdowns or pipeline terminations, with safety protocols followed in pressurized environments.

Company Background: Hebei Jiuyuan Pipeline Manufacturing Co., Ltd.

Hebei Jiuyuan Pipeline Manufacturing Co., Ltd. is a leading manufacturer of industrial piping components, including blind flanges. With a commitment to quality and innovation, the company adheres to international standards such as ASME, EN, and DIN. Their products are designed for durability, precision, and reliability, serving industries worldwide.

Why Choose Hebei Jiuyuan Pipeline?

Hebei Jiuyuan Pipeline Manufacturing Co., Ltd. stands out due to its:

- Extensive Product Range: From blind flange types to custom solutions for specialized applications.

- Quality Assurance: Rigorous testing and compliance with global standards.

- Customer-Centric Approach: Tailored support for industrial clients.

Standards and Compliance

The importance of standards in industrial manufacturing cannot be overstated. According to the National Institute of Standards and Technology (NIST), "standards play a crucial role in advancing technology by ensuring interoperability, safety, and efficiency" (NIST, 2025). Blind flanges manufactured by Hebei Jiuyuan comply with ASME, EN, JIS, and other international standards, reflecting the company's dedication to quality and precision.

Conclusion

Blind flanges are vital components in modern industrial systems, offering a reliable solution for sealing pipelines and pressure vessels. Their design, material options, and compliance with global standards make them indispensable in industries ranging from oil and gas to water treatment. Hebei Jiuyuan Pipeline Manufacturing Co., Ltd. continues to lead in this field, providing high-quality products that meet the demands of a rapidly evolving market. For more information, visit Blind Flange Product Page or explore the company website.

References

National Institute of Standards and Technology (NIST). (2025). Standards and Innovation. Retrieved from https://www.nist.gov/

-

May. 27, 2025

May. 27, 2025Plastic pipe fittings, in particular, are witnessing substantial growth due to their cost-effectiveness and versatility.

-

Apr. 28, 2025

Apr. 28, 2025From April 15 to April 19, 2025, our company proudly participated in the renowned Canton Fair held in Guangzhou, China.

If you are interested in our products, you can choose to leave your information here, and we will be in touch with you shortly.