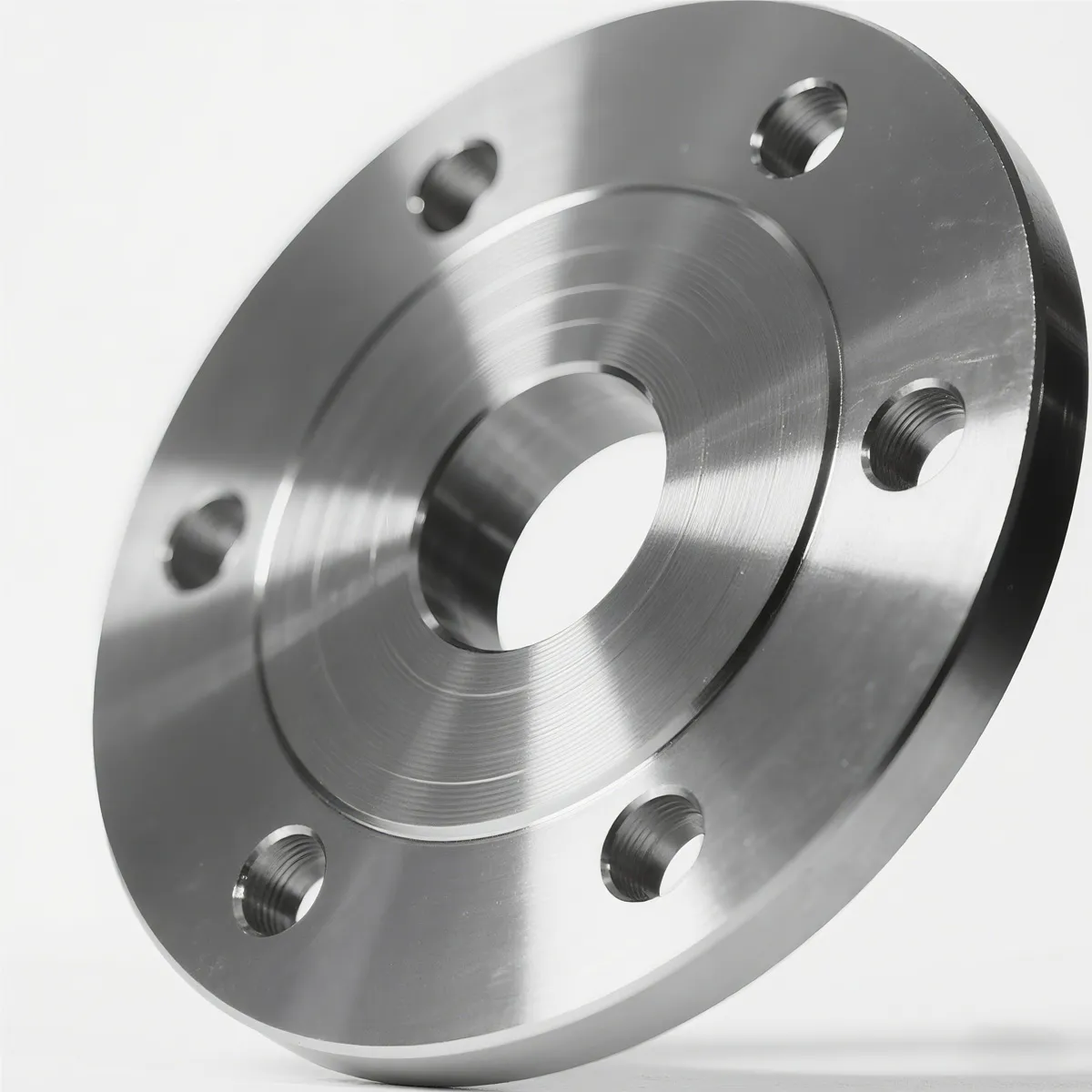

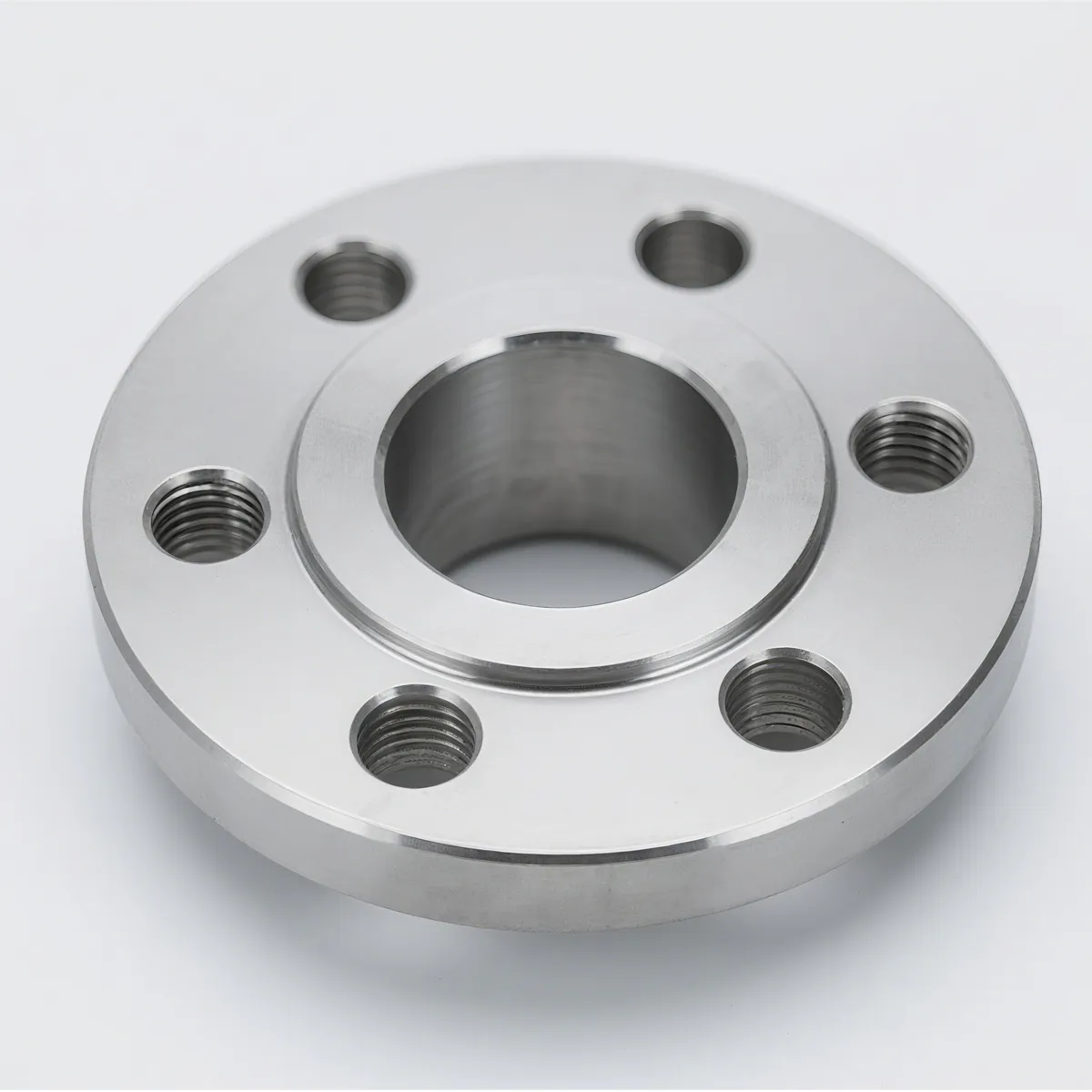

Slip-on weld flanges are designed for easy installation and reliable performance in a wide range of piping systems. These flanges slide over the pipe and are then welded both inside and outside to provide strength and prevent leakage. They are ideal for low-pressure and low-temperature applications, offering a cost-effective and efficient solution for connecting pipes, valves, and other equipment.

|

Slip-on Weld Flanges |

|

Description: Slip-on Weld Flanges |

|

PN/CLASS:PN6 - PN40/ Class150 - Class2500 |

|

DN/INCH:Dn10 - DN2000/ ½In - 24In/S.A 12In - 60In |

|

MAR:CS(ASTM A105P235GH/P245GH/P250GH/P265GH/ST37-2)SS(ASTM A182/304/306) |

|

STD: ASME/EN/JIS/DIN/BS/KS/GOST/SABS/ATK |

|

Surface Coating:Black paint/Galvanize/Grease/Epoxy paint |

|

Flanges have no internal stop. Slide a pipe through the flange and weld on both sides. |

Slip-on weld flanges are designed for easy installation and reliable performance in a wide range of piping systems. These flanges slide over the pipe and are then welded both inside and outside to provide strength and prevent leakage. They are ideal for low-pressure and low-temperature applications, offering a cost-effective and efficient solution for connecting pipes, valves, and other equipment.

Our slip-on weld flanges are engineered for ease of use, cost efficiency, and dependable sealing in piping systems. Manufactured from high-quality materials such as carbon steel, stainless steel, and alloy steel, they provide excellent durability and corrosion resistance. The slip-on design allows for quick alignment and installation, reducing labor time and ensuring a secure, leak-free connection when double welded. These flanges are suitable for a variety of industrial environments, including water treatment, petrochemical, and HVAC systems. With smooth bore alignment and compatibility with a wide range of pipe sizes, our slip-on weld flanges deliver long-lasting performance and simplified maintenance.

Slip-on weld flanges are widely used in various industries due to their ease of installation and cost-effectiveness. These flanges are ideal for low- to medium-pressure piping systems where frequent disassembly is not required. Common applications include water supply lines, HVAC systems, oil and gas pipelines, chemical processing plants, and fire protection systems. Their ability to slide over the pipe before welding makes them perfect for systems that require precise alignment and flexibility during assembly. Slip-on flanges are especially useful in applications where space is limited, or where quick, secure connections are essential. They are also well-suited for use with both liquid and gas transport systems, providing reliable performance and long-term durability. Whether in industrial, commercial, or municipal projects, slip-on weld flanges offer a dependable solution for building and maintaining efficient piping networks.

What is a slip-on weld flange?

A slip-on weld flange is a type of pipe flange designed to slide over the end of a pipe and be welded in place, both inside and outside, to create a secure, leak-proof connection. It is commonly used in low- to medium-pressure piping systems where ease of installation and cost-efficiency are priorities. The slip-on design allows for easier alignment compared to other flange types, making it ideal for systems that require quick assembly and less precision in pipe cutting. These flanges are typically made from materials like carbon steel, stainless steel, or alloy steel to ensure durability and corrosion resistance. Slip-on weld flanges are widely used in applications such as water supply, oil and gas transport, chemical processing, and HVAC systems. Their versatility, simple construction, and reliable sealing performance make them a preferred choice for general-purpose piping in both industrial and commercial settings.

What is the difference between lap joint flanges and slip-on flanges?

The main difference between lap joint flanges and slip-on flanges lies in their design and installation method. Lap joint flanges consist of two parts: a loose backing flange and a stub end welded to the pipe. The backing flange can rotate around the stub end, allowing for easy alignment, making it ideal for systems that require frequent disassembly or where pipe misalignment may occur. On the other hand, slip-on flanges are designed to slide directly over the pipe and are then welded both on the inside and outside, creating a fixed, strong connection. Slip-on flanges are easier to install than lap joint flanges because they do not require a separate stub end, making them a cost-effective option for low- to medium-pressure systems. While lap joint flanges offer flexibility in alignment, slip-on flanges provide a more secure and robust connection. Both flange types are commonly used in various industrial applications, but lap joint flanges are preferred in corrosive environments or systems requiring easy access and disassembly, while slip-on flanges are often used in general piping systems.