Blind flanges are solid disks used to block off a pipeline, valve, or pressure vessel opening. They are designed for easy installation and removal, making them ideal for applications requiring frequent inspection or maintenance.

|

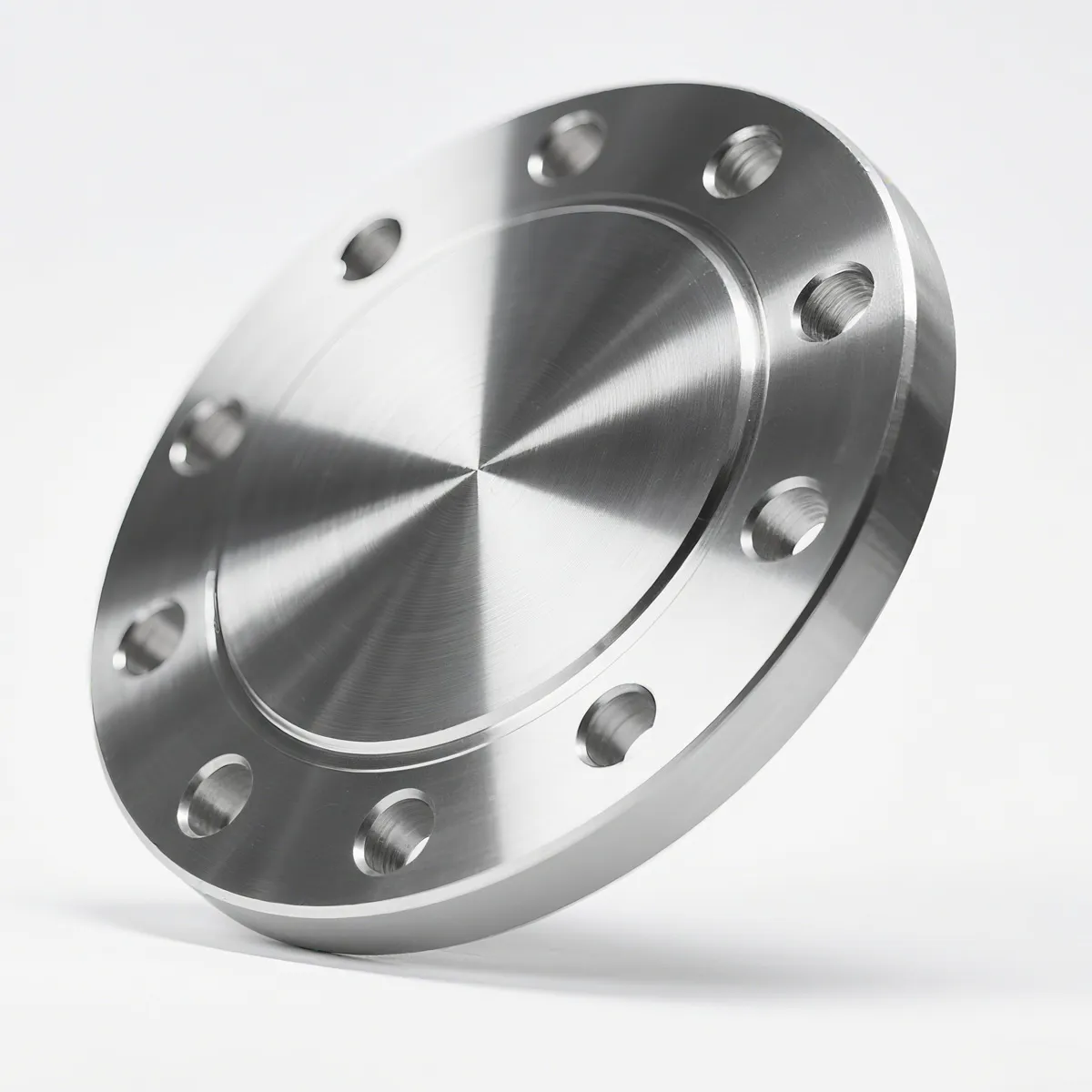

Blind Flange |

|

Description:Blind Flange |

|

PN/CLASS:PN6 - PN40/ Class150 - Class2500 |

|

DN/INCH:Dn10 - DN2000/ ½In - 24In/S.A 12In - 60In |

|

MAR:CS(ASTM A105P235GH/P245GH/P250GH/P265GH/ST37-2)SS(ASTM A182/304/306) |

|

STD: ASME/EN/JIS/DIN/BS/KS/GOST/SABS/ATK |

|

Surface Coating:Black paint/Galvanize/Grease/Epoxy paint |

|

Bolt two flat-surface flanges or two raised-surface flanges of the same size together with a gasket (sold separately) to create an access point in a pipe line. Flanges are for use with low-pressure applications in noncorrosive environments. |

Blind flanges are solid disks used to block off a pipeline, valve, or pressure vessel opening. They are designed for easy installation and removal, making them ideal for applications requiring frequent inspection or maintenance. Manufactured in a variety of materials such as carbon steel, stainless steel, and alloy steel, blind flanges offer excellent strength, durability, and resistance to pressure and temperature. Available in various pressure ratings (ANSI/ASME, DIN, JIS, etc.), they ensure secure sealing and compatibility with international standards. Blind flanges are widely used in industries like oil & gas, petrochemical, power generation, and water treatment.

Blind Flange Application

Blind flanges are commonly used in piping systems to seal the end of a pipeline, valve, or pressure vessel opening. They are essential for systems that require future expansion, inspection, or maintenance. Blind flanges are widely applied in industries such as oil and gas, chemical processing, petrochemicals, power generation, water treatment, and shipbuilding. They are particularly useful in high-pressure and high-temperature environments where a secure and leak-proof seal is critical. By providing a strong barrier, blind flanges help ensure system integrity and operational safety.

What is a blind flange?

A blind flange is a type of flange used to seal the end of a piping system or pressure vessel opening. Unlike other flanges, it has no center hole, making it ideal for stopping the flow of fluids or gases. Blind flanges are commonly used when a pipeline needs to be closed off temporarily or permanently, or when future expansion or maintenance is anticipated. They are bolted onto matching flanges and can be easily removed and reinstalled when needed.

Manufactured in various materials such as carbon steel, stainless steel, and alloy steel, blind flanges are available in a wide range of sizes and pressure ratings to meet different industrial requirements. They are designed to withstand high pressure and temperature conditions, providing a secure, leak-proof seal.

Blind flanges are widely used in industries such as oil and gas, chemical processing, water treatment, power generation, and shipbuilding. Their robust design and ease of use make them a practical solution for sealing off piping systems while allowing for future access. Additionally, blind flanges are often used during pressure testing of pipelines, ensuring the system is safe and leak-free before operation.

How do you install a blind flange?

Installing a blind flange involves sealing the end of a piping system securely to stop flow or allow for future access. The process begins by ensuring that the flange faces and gaskets are clean and free of debris. A suitable gasket, compatible with the fluid and pressure in the system, is placed between the blind flange and the mating flange.

Next, align the bolt holes of both flanges and insert the bolts. It's important to use the correct number and grade of bolts as specified by the flange rating. The bolts should be tightened gradually in a crisscross (star) pattern to ensure even pressure across the sealing surface. This prevents warping and ensures a leak-proof connection.

A torque wrench is recommended for applying consistent and proper torque to each bolt, following the manufacturer’s specifications. After installation, the system may be pressure-tested to check for leaks and ensure a secure seal.

Blind flange installation is commonly performed during system shutdowns or pipeline terminations and is designed for easy removal when the line needs to be extended, opened, or maintained. Safety precautions should always be followed, especially in pressurized systems or hazardous environments.