- Pipe Fitting

- Cast Products

- HEXAGON NUT (LN)

- WELDING NPPLE (WN)

- SOCKET PLAIN (SPU)

- COUPLING O.D.MACHINED (SPE)

- 90 ELBOW(90LB)

- 45 ELBOW(45LB)

- CAP (CB)

- BARREL NIPPLE (BN)

- SOCKET BANDED(SB)

- UNION(CU)

- REDUCING SOCKET BANDED (RSB)

- REDUCING TEE (RTB)

- REDUCING HEXAGON NIPPLE(RHN)

- SQUARE PLUG (SQ)

- CROSS (十B)

- TEE(TB)

- HOSE NIPPLE (HON)

- UNION M,F(CU MF)

- HEXAGON NIPPLE(HN)

- HEXAGON PLUG (HP)

- HEXAGON HEAD CAP(HCB)

- HEXAGON BUSHING(HB)

- Forged Products

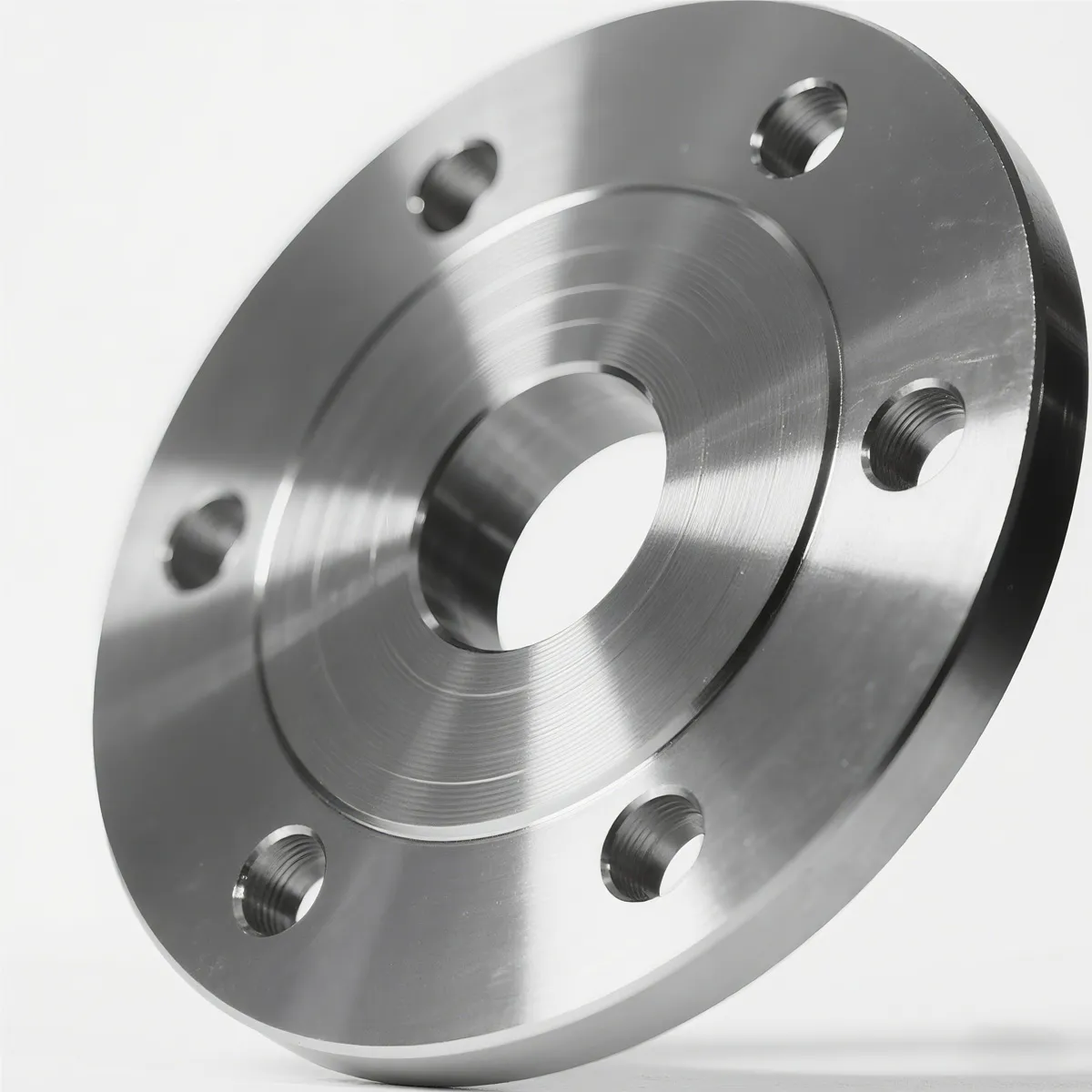

- Flange

The Long Neck Flange, also known as the Weld Neck Flange, is designed for high-pressure and high-temperature applications. It features a long tapered hub that gradually merges with the pipe, providing excellent stress distribution and reducing the risk of deformation.

|

Long Neck Flange |

|

产品描述/Description:长颈法兰 Long Neck Flange |

|

PN/CLASS:PN6 - PN40/ Class150 - Class2500 |

|

DN/INCH:Dn10 - DN2000/ ½In - 24In/S.A 12In - 60In |

|

材料/MAR:CS(ASTM A105P235GH/P245GH/P250GH/P265GH/ST37-2)SS(ASTM A182/304/306) |

|

STD: ASME/EN/JIS/DIN/BS/KS/GOST/SABS/ATK |

|

Surface Coating:Black paint/Galvanize/Grease/Epoxy paint |

|

Flanges are also known as weld-neck flanges. The flange neck has a beveled end that, when flush to pipe, creates a trough for a strong weld. |

The Long Neck Flange, also known as the Weld Neck Flange, is designed for high-pressure and high-temperature applications. It features a long tapered hub that gradually merges with the pipe, providing excellent stress distribution and reducing the risk of deformation.

This design ensures strong structural integrity and minimizes turbulence and erosion at the joint. Made from various materials such as carbon steel, stainless steel, and alloy steel, Long Neck Flanges offer durability and resistance to corrosion. They are ideal for use in pipelines, refineries, power plants, and chemical industries, where reliability and safety are critical.

1.Oil and Gas Industry: Long Neck Flanges are widely used in upstream and downstream operations, including pipelines, refineries, and offshore platforms. Their robust design ensures leak-proof connections, which are critical in transporting oil, gas, and other hydrocarbons safely over long distances.

2.Power Generation: In thermal, nuclear, and gas power plants, Long Neck Flanges are used to connect high-pressure steam, water, and gas lines. Their ability to endure extreme temperatures and provide stable flow makes them suitable for boilers, turbines, and heat exchangers.

3.Chemical and Petrochemical Industry: These flanges are used in systems that handle corrosive or hazardous chemicals. The long neck provides excellent stress distribution and reduces turbulence, ensuring safe and reliable operation in reactors, distillation columns, and chemical transport pipelines.