Socket weld flanges are designed for small-diameter, high-pressure piping systems. They feature a recessed socket into which the pipe is inserted before welding, providing a smooth bore and better flow characteristics. This design ensures strong, leak-proof joints while simplifying alignment during installation.

|

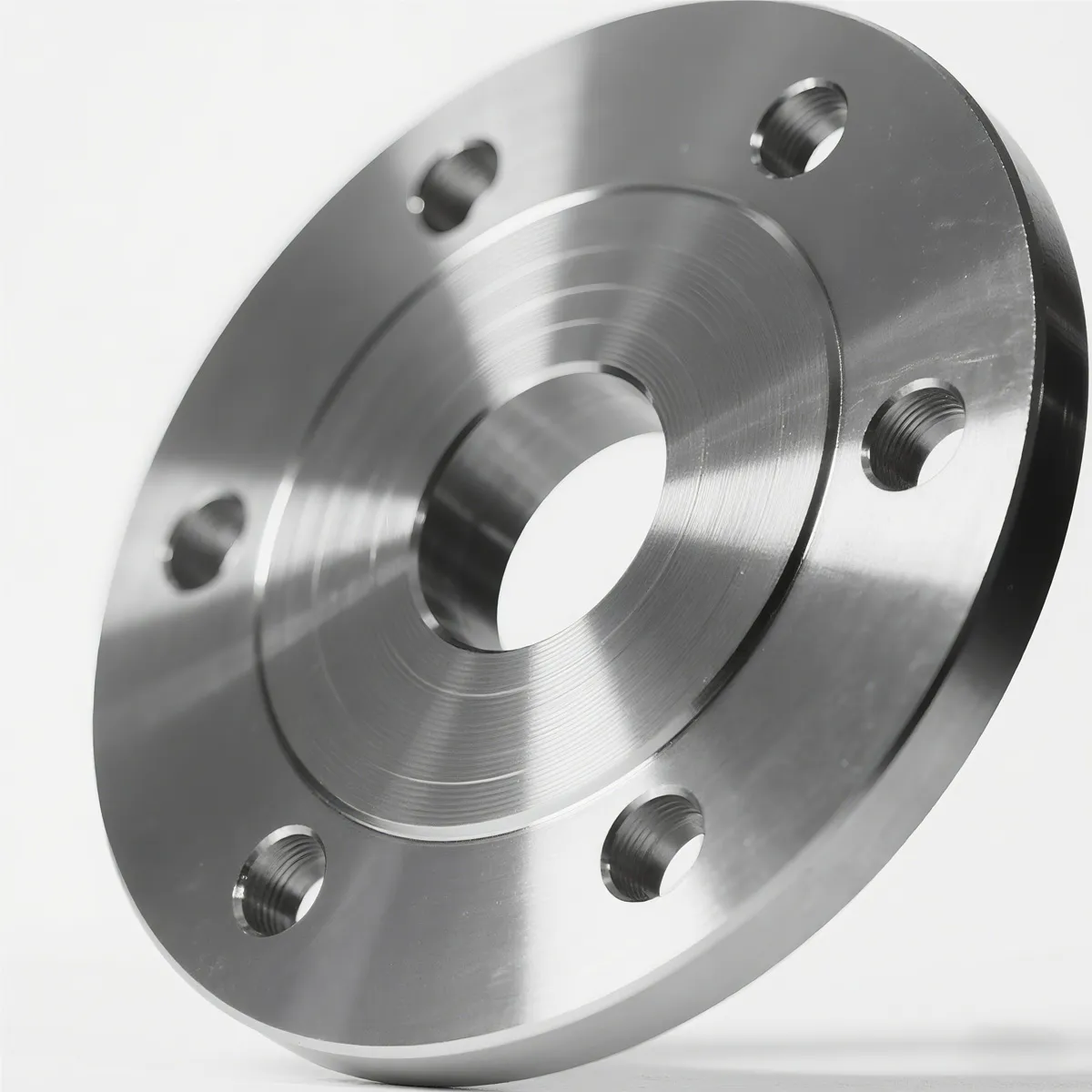

Socket Weld Flange |

|

Description: Socket Weld Flange |

|

PN/CLASS:PN6 - PN40/ Class150 - Class2500 |

|

DN/INCH:Dn10 - DN2000/ ½In - 24In/S.A 12In - 60In |

|

MAR:CS(ASTM A105P235GH/P245GH/P250GH/P265GH/ST37-2)SS(ASTM A182/304/306) |

|

STD: ASME/EN/JIS/DIN/BS/KS/GOST/SABS/ATK |

|

Surface Coating:Black paint/Galvanize/Grease/Epoxy paint |

|

Connect flanges have an internal stop that supports the pipe when welding and prevents the pipe from sliding all the way through. |

Socket weld flanges are designed for small-diameter, high-pressure piping systems. They feature a recessed socket into which the pipe is inserted before welding, providing a smooth bore and better flow characteristics. This design ensures strong, leak-proof joints while simplifying alignment during installation. Socket weld flanges are ideal for applications where the use of threaded connections is not suitable due to leakage risks. Made from durable materials like carbon steel, stainless steel, and alloy steel, they offer excellent mechanical strength and corrosion resistance. Socket weld flanges are commonly used in high-pressure systems, including oil & gas, chemical processing, and power generation, and conform to standards such as ASME B16.5.

Socket Weld Flange Application

Socket weld flanges are commonly used in small-diameter, high-pressure piping systems where a strong, leak-proof connection is critical. These flanges are ideal for industries such as oil and gas, petrochemical, power generation, and water treatment, where reliable and secure joints are required to withstand elevated pressures and harsh conditions. Socket weld flanges are typically used in systems that transport gases, liquids, or slurries under high-pressure conditions, such as in steam lines, hydraulic systems, and process piping. The design of the socket weld flange allows for easy alignment and provides a smooth flow path, reducing turbulence and pressure drop. Its robust construction ensures long-lasting performance, making it a preferred choice for critical applications where safety and efficiency are paramount.

What is a socket weld flange?

A socket weld flange is a type of flange that is commonly used for joining small-diameter pipes in high-pressure systems. Unlike other flanges, a socket weld flange features a recessed area (or socket) into which the pipe is inserted before welding. This design allows for a smooth and continuous flow path, which reduces the risk of turbulence and pressure drops. The pipe is welded inside the socket, creating a strong, leak-proof connection.

Socket weld flanges are typically used in industries such as oil and gas, chemical processing, power generation, and water treatment, where high-pressure and high-temperature conditions are common. The flanges are usually made from materials such as carbon steel, stainless steel, and alloy steel to ensure strength, durability, and corrosion resistance.

One of the key advantages of socket weld flanges is that they allow for easy alignment during installation, which simplifies the welding process. Additionally, the design reduces the chances of leakage compared to threaded connections. Socket weld flanges are most suitable for applications in systems with small-diameter piping, typically under 2 inches in diameter, and they conform to standards like ASME B16.5, ensuring reliable performance.

Socket weld flange standard

The Socket Weld Flange Standard refers to the established guidelines for the design, dimensions, and construction of socket weld flanges, ensuring consistency, safety, and performance across various piping systems. The most commonly referenced standard for socket weld flanges is ASME B16.5, which covers flanges made from materials such as carbon steel, stainless steel, and alloy steel. This standard specifies the dimensions, pressure ratings, material specifications, and testing requirements for socket weld flanges used in piping systems.

Socket weld flanges are typically designed for smaller diameter pipes (usually 2 inches or less), and their standardization ensures compatibility across various systems. The flanges feature a socket where the pipe is inserted before welding, providing a secure, leak-proof joint. The ASME B16.5 standard also outlines the necessary details for flange faces, bolt holes, and welding procedures to achieve strong, reliable connections.

In addition to ASME B16.5, socket weld flanges may also conform to other international standards such as API 6A for oil and gas applications or DIN standards for European markets. Adhering to these standards is essential for ensuring the integrity and safety of piping systems in industries such as oil and gas, power generation, and chemical processing.