- Albanian

- Arabic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bulgarian

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Finnish

- French

- German

- Greek

- Hebrew

- Hungarian

- Indonesian

- irish

- Italian

- Japanese

- Khmer

- Korean

- Kyrgyz

- Lao

- Latin

- Lithuanian

- Malay

- Myanmar

- Norwegian

- Persian

- Polish

- Portuguese

- Romanian

- Russian

- Serbian

- Slovak

- Slovenian

- Spanish

- Swedish

- Tagalog

- Thai

- Turkish

- Turkmen

- Uzbek

- Vietnamese

- Zulu

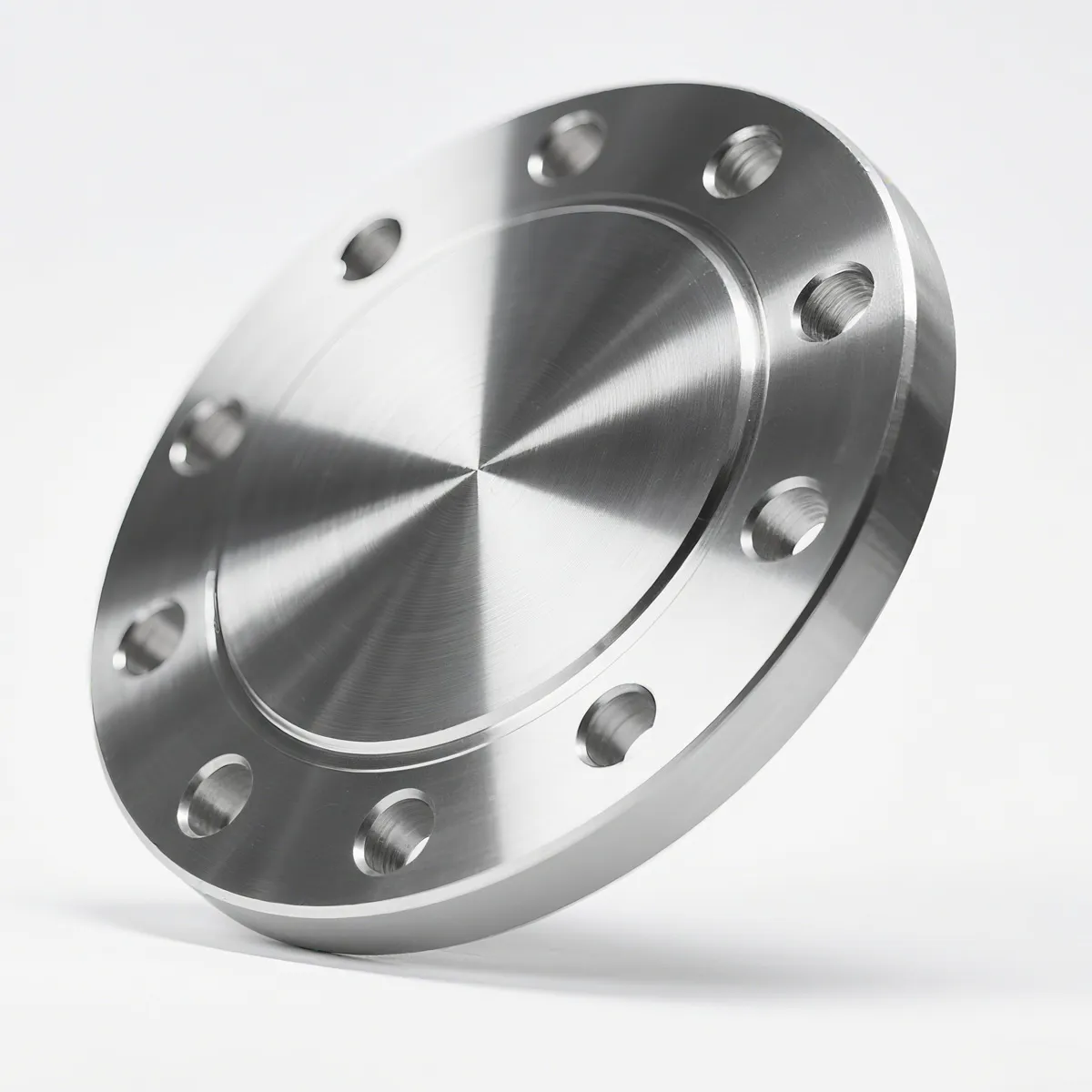

Introduction to Blind Flanges

A blind flange is a critical component in piping systems, designed to seal the end of a pipeline, valve, or pressure vessel. Unlike other flanges, blind flanges lack a central opening, making them ideal for blocking the flow of fluids or gases. These solid disks are engineered for easy installation and removal, offering flexibility for maintenance, inspection, and future system modifications. Their robust design and compatibility with international standards ensure reliability in diverse industrial environments.

The Blind Flange from HEBEI JIUYUAN PIPELINE MANUFACTURING CO., LTD. exemplifies this technology, combining durability with precision. This article delves into the product's features, technical specifications, applications, and the company's commitment to quality, while referencing authoritative sources like the National Institute of Standards and Technology (NIST) to validate its compliance with global standards.

Product Features and Advantages

Blind flanges are engineered to meet the demands of modern industrial systems. Key features include:

- Material Variety: Available in carbon steel (ASTM A105, P235GH, P245GH), stainless steel (ASTM A182, 304, 306), and alloy steel, ensuring resistance to corrosion, high pressure, and extreme temperatures.

- Pressure and Size Range: Designed for PN6 to PN40 (Class 150 to Class 2500) and DN10 to DN2000 (½ inch to 24 inches), accommodating both low- and high-pressure applications.

- Surface Coatings: Options include black paint, galvanization, grease, and epoxy paint, enhancing longevity in noncorrosive environments.

- Compliance with Standards: Adheres to ASME, EN, JIS, DIN, BS, KS, GOST, and SABS standards, ensuring interoperability across global systems.

The Blind Flange is particularly valued for its easy installation and removal, which minimizes downtime during maintenance. Its design allows for secure sealing with gaskets, which are sold separately. This flexibility makes it a preferred choice for systems requiring frequent access or modifications.

Technical Specifications

| Parameter | Details |

|---|---|

| Pressure Rating | PN6 - PN40 / Class 150 - Class 2500 |

| Diameter Range | DN10 - DN2000 / ½ inch - 24 inches / 12 inches - 60 inches |

| Materials | Carbon Steel (ASTM A105, P235GH, P245GH, P250GH, P265GH, ST37-2), Stainless Steel (ASTM A182, 304, 306) |

| Standards | ASME, EN, JIS, DIN, BS, KS, GOST, SABS, ATK |

| Surface Coating | Black paint, Galvanize, Grease, Epoxy paint |

| Application | Low-pressure noncorrosive environments, pipeline sealing, valve and pressure vessel closure |

Applications in Industrial Systems

Blind flanges are indispensable in industries where system integrity and safety are paramount. Key applications include:

- Oil and Gas: Sealing pipelines and valves during maintenance or expansion.

- Chemical Processing: Preventing leaks in corrosive environments with stainless steel variants.

- Power Generation: Ensuring secure connections in high-temperature and high-pressure systems.

- Water Treatment: Blocking access points for inspection or upgrades without disrupting operations.

- Shipbuilding: Providing reliable sealing in marine piping systems.

The Blind Flange is particularly suited for high-pressure and high-temperature environments, where a leak-proof seal is critical. According to the National Institute of Standards and Technology (NIST), adherence to standardized measurements and material specifications ensures the reliability of such components in critical infrastructure.

Installation Guide

Proper installation of a blind flange is crucial for optimal performance. Follow these steps:

- Preparation: Clean the flange faces and gasket to remove debris. Ensure the gasket is compatible with the system's fluid and pressure.

- Alignment: Match the bolt holes of the blind flange with the mating flange. Insert bolts and tighten them gradually in a crisscross pattern to distribute pressure evenly.

- Securing: Use a torque wrench to apply consistent torque as specified by the flange rating. Avoid over-tightening to prevent warping.

- Testing: Conduct a pressure test to verify the seal's integrity. This step is essential for systems operating under high pressure or in hazardous environments.

Installation is often performed during system shutdowns or pipeline terminations, allowing for easy removal when future access is required. Safety protocols must be strictly followed, especially in pressurized systems, to prevent accidents.

Company Background: HEBEI JIUYUAN PIPELINE MANUFACTURING CO., LTD.

HEBEI JIUYUAN PIPELINE MANUFACTURING CO., LTD. is a leading manufacturer of industrial piping components, specializing in blind flanges and other critical equipment. With a focus on quality and innovation, the company adheres to international standards to deliver products that meet the highest industry benchmarks.

As highlighted by the National Institute of Standards and Technology (NIST), the importance of standardized manufacturing processes cannot be overstated. HEBEI JIUYUAN's commitment to compliance with ASME, EN, and DIN standards ensures that their products are trusted globally. Their expertise in materials science and engineering enables the production of durable, high-performance components tailored to diverse industrial needs.

Images of Blind Flange Types

Explore the different types of blind flanges available:

Conclusion

The Blind Flange from HEBEI JIUYUAN PIPELINE MANUFACTURING CO., LTD. is a testament to advanced engineering and adherence to global standards. Its versatility, durability, and compliance with international specifications make it a vital component in industrial piping systems. As emphasized by the National Institute of Standards and Technology (NIST), the precision and reliability of such products are essential for maintaining the safety and efficiency of critical infrastructure.

References

National Institute of Standards and Technology (NIST). (n.d.). Standards and Measurements. Retrieved from https://www.nist.gov/

-

Apr. 24, 2025

Apr. 24, 2025Jiuyuan Pipeline is excited to announce its participation in the upcoming 2025 Wire / Tube with Metal & Steel KSA exhibition, scheduled from May 5th to May 7th, 2025.

-

May. 27, 2025

May. 27, 2025Plastic pipe fittings, in particular, are witnessing substantial growth due to their cost-effectiveness and versatility.

If you are interested in our products, you can choose to leave your information here, and we will be in touch with you shortly.