Understanding Slip-On Weld Flanges: Market Dynamics and Industry Adoption

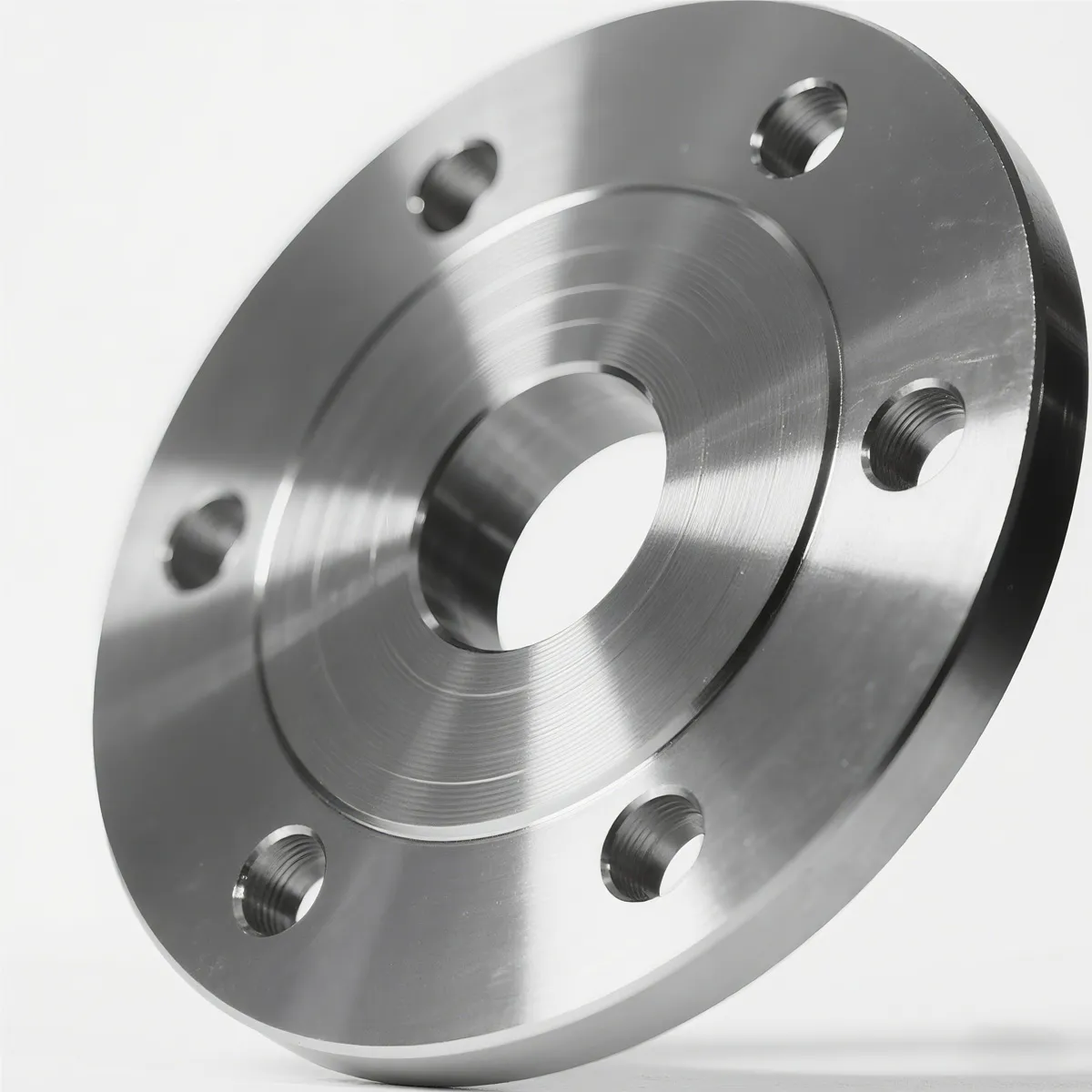

In the intricate world of industrial piping systems, the choice of components significantly impacts operational integrity, safety, and longevity. Among the myriad of available flange types, slip on weld flanges stand out for their exceptional blend of versatility, ease of installation, and cost-effectiveness, making them a cornerstone in various sectors. These flanges are designed to slide over the end of a pipe, then be welded both inside and out, providing sufficient strength and preventing leakage. The current industry landscape is witnessing a robust demand for these components, driven by global infrastructure development, expansion in the oil and gas, petrochemical, and power generation sectors, alongside a burgeoning focus on water treatment and distribution networks. Market analysis indicates a steady growth trajectory, propelled by their adaptability to different pressure classes and pipe sizes, as well as their inherent advantage in applications requiring quick assembly and disassembly for maintenance or system modifications. Furthermore, advancements in material science and manufacturing precision have enhanced their performance parameters, reinforcing their position as a preferred choice for engineers and procurement specialists seeking reliable and economically viable piping solutions. The ongoing global emphasis on energy efficiency and environmental compliance also necessitates components that contribute to system integrity and minimize fugitive emissions, areas where properly installed slip-on flanges excel due to their secure double-welded connection.

Technical Specifications and Material Excellence of Slip-On Flanges

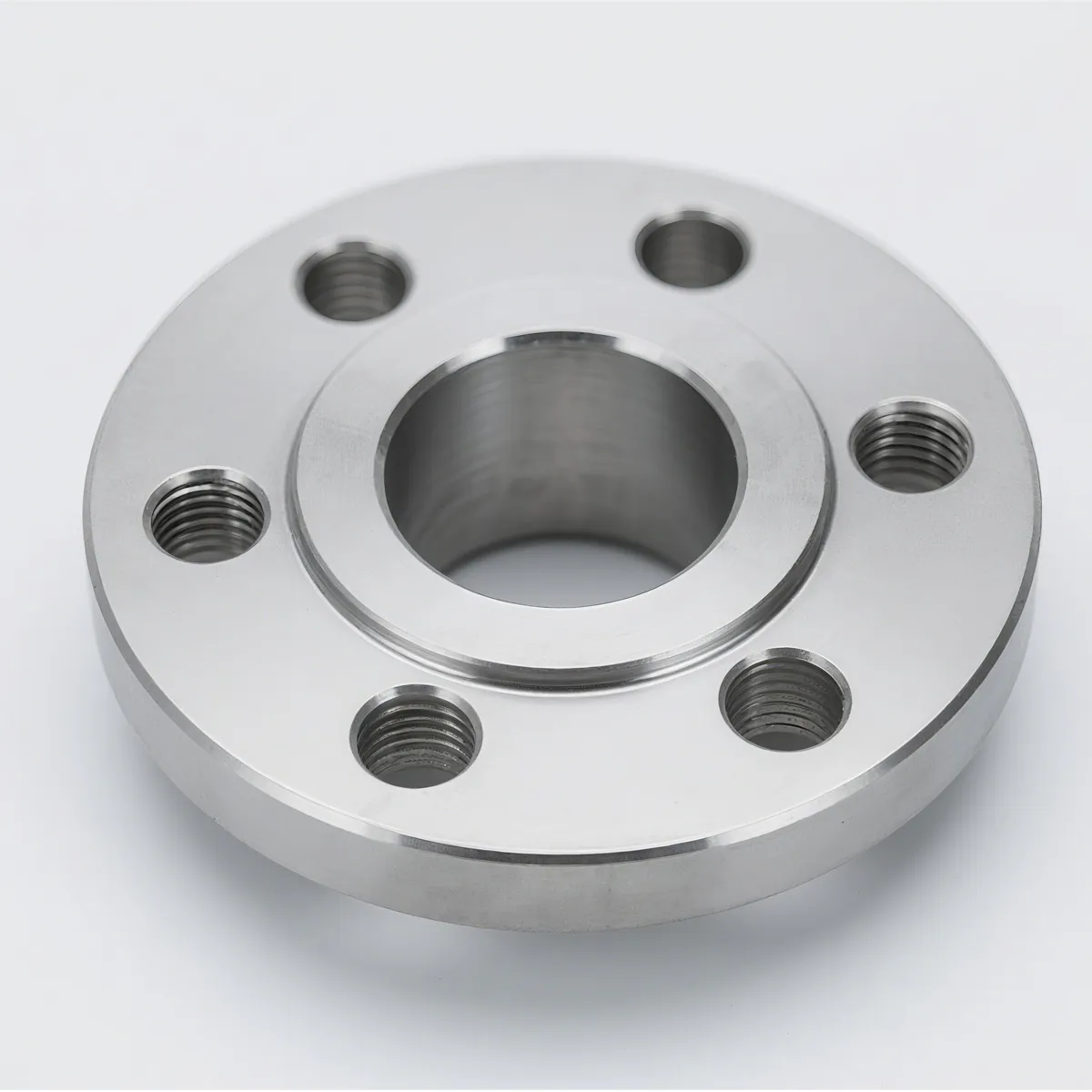

The performance of any piping component is intrinsically linked to its technical specifications and the integrity of its constituent materials. Slip on weld flanges are typically manufactured according to international standards such as ASME B16.5, ASME B16.47, DIN, EN, and JIS, ensuring interchangeability and reliability across diverse global projects. These standards define critical parameters including nominal pipe size (NPS), pressure classes (e.g., Class 150, 300, 600, 900, 1500, 2500), facing types (flat face, raised face, ring type joint), and dimensional tolerances. Common materials for these flanges include carbon steel (ASTM A105, A350 LF2), stainless steel (ASTM A182 F304/304L, F316/316L, F321), and alloy steel (ASTM A182 F5, F9, F11, F22, F91). The selection of material is paramount and is dictated by the service conditions, including operating temperature, pressure, and the corrosive nature of the fluid being transported. For instance, in petrochemical applications dealing with aggressive chemicals, stainless steel or specific alloy steels are preferred due to their superior corrosion resistance and high-temperature strength. Conversely, for general utility lines or less corrosive environments, carbon steel offers a cost-effective and robust solution. The bore of a flange slip on welding is specifically sized to allow the pipe to easily slide into it, facilitating quick alignment and tack welding before the final full penetration welds are applied both on the outside and the inside of the flange. This design choice simplifies fabrication and reduces the precision required for pipe cutting compared to butt-weld designs.

| Parameter | Description | Common Values/Standards |

|---|---|---|

| Nominal Pipe Size (NPS) | Pipe Diameter Compatibility | 1/2" to 24" (ASME B16.5); Larger for B16.47 |

| Pressure Class | Maximum Allowable Pressure Rating | Class 150, 300, 600, 900, 1500, 2500 |

| Materials | Construction Material for Flange | Carbon Steel (A105), Stainless Steel (304/316), Alloy Steel |

| Facing Type | Gasket Sealing Surface Configuration | Raised Face (RF), Flat Face (FF) |

| Bore Type | Internal Diameter of Flange Hub | Designed to slide over pipe |

| Manufacturing Standards | Industry Design and Dimension Specifications | ASME B16.5, ASME B16.47, DIN, EN, JIS |

The Advanced Manufacturing Process of Slip-On Weld Flanges

The production of high-quality slip on weld flanges is a sophisticated process involving several critical stages, each contributing to the final product's integrity and performance. The journey typically begins with material procurement, where raw materials—such as carbon steel billets, stainless steel bars, or alloy steel ingots—are carefully selected based on their chemical composition and mechanical properties, adhering strictly to standards like ASTM or EN. The primary forming method can be either forging or casting. Forged flanges, made by heating and hammering/pressing solid metal into shape, offer superior mechanical properties, including enhanced grain structure and resistance to impact and fatigue, making them ideal for high-pressure or high-stress applications. Cast flanges, poured as molten metal into molds, are suitable for less demanding applications and offer greater design flexibility for complex shapes. Following the initial forming, the flanges undergo precise CNC machining. This stage involves turning, drilling, and facing operations to achieve the exact dimensions, bolt hole patterns, and surface finishes specified by standards like ASME B16.5. Precision machining ensures perfect alignment with mating components and optimal sealing. Crucially, strict quality control and inspection standards are applied throughout the manufacturing lifecycle. This includes material traceability, dimensional checks using calibrated instruments, visual inspection for surface defects, and non-destructive testing (NDT) methods such as ultrasonic testing (UT), magnetic particle inspection (MPI), liquid penetrant testing (LPT), and radiographic testing (RT) to detect internal flaws. Pressure testing and hydrostatic testing may also be performed to verify their leak-tightness and structural integrity under simulated operating conditions. Adherence to international quality management systems, such as ISO 9001, is paramount, ensuring consistent product quality, extended service life (often exceeding 20-30 years in non-corrosive environments), and suitability for demanding industries like petrochemical, oil and gas, power generation, and water treatment, where reliability and safety are non-negotiable.

Applications and Distinct Advantages of Slip-On Weld Flanges

The adaptability and robust design of slip on weld flanges make them indispensable across a wide spectrum of industrial applications. They are commonly found in low-pressure and moderate-temperature systems where pipe alignment is less critical but cost-effectiveness and ease of assembly are prioritized. Key application sectors include the chemical processing industry, where they connect various vessels and pipelines; water and wastewater treatment plants, for efficient fluid conveyance; fire protection systems, ensuring reliable water flow; and general industrial utility services, such as steam, air, and inert gas lines. In the oil and gas sector, particularly within refinery operations and upstream facilities, they are utilized for connecting process lines that do not experience severe thermal cycling or extreme pressures, often chosen for their simpler installation compared to slip on weld neck flange types. A primary technical advantage of these flanges is their straightforward installation process. The ability to "slip on" the pipe allows for slight adjustments in pipe length before welding, significantly reducing the precision required for cutting pipes to exact dimensions, thereby saving time and labor costs during fabrication. The dual internal and external welding provides a strong, durable, and leak-resistant connection, ensuring system integrity and minimizing maintenance requirements. While they are not typically recommended for very high-pressure or high-temperature applications or where severe thermal shock may occur, their cost-efficiency and ease of alignment in appropriate scenarios translate into tangible benefits, including reduced installation time, lower overall project costs, and reliable performance over a long operational lifespan. This efficiency can also contribute to indirect energy savings by minimizing potential leak points and maintaining system pressure.

Custom Solutions and Strategic Manufacturer Selection

For B2B clients, the availability of customized solutions for slip on weld flanges is often as crucial as standard offerings. While global standards like ASME B16.5 cover a vast range of specifications, specific project requirements may necessitate deviations in material grades, dimensions, bore sizes, or unique facing configurations. A reputable manufacturer should possess the engineering capabilities and production flexibility to accommodate such bespoke demands, offering solutions tailored to unique operational pressures, corrosive environments, or space constraints. When evaluating manufacturers, several factors are paramount to ensure authority and trustworthiness. Firstly, certifications such as ISO 9001 for quality management, API (American Petroleum Institute) certifications for oil and gas applications, and compliance with specific regional directives like PED (Pressure Equipment Directive) for European markets, signify a manufacturer's commitment to quality and safety. Secondly, a proven track record, evidenced by years of service in the industry and a portfolio of successfully completed projects, reflects their experience and reliability. Third, transparent communication regarding lead times, delivery schedules, and quality control processes builds trust. Finally, comprehensive technical support, including assistance with material selection, design optimization, and post-sales service, is indicative of a client-centric approach. Manufacturers who invest in advanced production technologies, such as automated welding and robotic machining, often deliver products with higher precision and consistency. Collaborating with a manufacturer who can provide detailed material test reports (MTRs) and performance data, alongside competitive pricing, ensures that projects benefit from both high-quality components and optimal cost-efficiency, mitigating risks associated with material failures or operational disruptions.

Choosing a Reliable Slip-On Weld Flange Manufacturer: Key Criteria

- Certifications & Compliance: ISO 9001, API, PED, and adherence to international standards (ASME, DIN).

- Experience & Reputation: Years in the industry, client testimonials, and successful project case studies.

- Customization Capability: Ability to produce bespoke designs, materials, and sizes to meet specific project needs.

- Quality Assurance: Robust QC processes, NDT capabilities, and provision of Material Test Reports (MTRs).

- Technical Support: Pre-sales consultation, design assistance, and post-sales technical service.

- Delivery & Logistics: Reliable lead times, efficient global shipping capabilities.

Real-World Impact: Case Studies and Client Success with Slip-On Weld Flanges

The practical effectiveness of slip on weld flanges is best illustrated through real-world application scenarios and positive client feedback. For instance, a leading petrochemical complex recently undertook a major expansion project involving numerous utility lines and non-critical process piping. The client opted for our standard carbon steel slip-on flanges (ASME B16.5, Class 150 RF) for their ease of installation and cost-efficiency. Our technical team provided detailed engineering support, ensuring optimal material selection and fit-up procedures. The project reported a 15% reduction in overall installation time compared to previous projects utilizing weld neck flanges, primarily due to the simplified alignment and welding process inherent to the slip-on design. This translated into significant labor cost savings and expedited project completion. Another compelling case involved a municipal water treatment facility upgrading its pump stations. The project required hundreds of stainless steel flange slip on welding units (ASTM A182 F316L) to resist corrosion from treated water. Our ability to supply custom-bored flanges to accommodate varying pipe schedules, coupled with a guaranteed rapid delivery schedule, was critical. The project manager noted that the consistency in flange dimensions and superior surface finish minimized gasket sealing issues, ensuring a leak-free system upon commissioning. Furthermore, a long-standing client in the pulp and paper industry, facing recurring issues with flange leakage in their steam lines, implemented our high-grade alloy steel slip-on flanges. Post-installation, the facility reported a dramatic decrease in steam leaks, leading to substantial energy savings and reduced maintenance downtime, validating the long-term reliability and robustness of our products even in challenging environments. These instances underscore how the correct application of these components, backed by robust manufacturing and technical support, delivers measurable operational benefits and enhanced system reliability for diverse industrial operations.

Ensuring Trust: FAQs, Quality Assurance, and Customer Support

Building and maintaining trust with B2B clients is paramount, and this extends beyond product quality to encompass comprehensive support and transparent practices. We prioritize clarity and reliability, offering detailed insights into our operations and commitments. Our quality assurance framework for slip on weld flanges is rigorous, commencing from the careful selection of raw materials, through meticulous in-process controls, to final product inspection. Every batch undergoes stringent testing, including material composition analysis, mechanical property tests (tensile strength, yield strength, hardness), and dimensional verification, ensuring full compliance with ASME, ANSI, and ISO standards. We provide full material traceability and comprehensive test certificates with every order. Our typical delivery cycle for standard flanges ranges from 2 to 4 weeks, with expedited options available for urgent requirements, while customized solutions may require slightly longer lead times depending on complexity. We stand by the quality of our products with a robust warranty policy, covering manufacturing defects for a specified period (e.g., 12-24 months from installation or 18-30 months from shipment, whichever comes first). Our dedicated customer support team is available to assist with technical queries, order tracking, and any post-delivery concerns, ensuring a seamless experience from inquiry to installation. We also maintain a comprehensive FAQ section to address common concerns proactively. For example, a frequently asked question is whether slip on weld neck flange types are always superior; the answer clarifies that while weld necks offer higher integrity for extreme conditions, slip-ons provide cost and installation advantages for appropriate applications. Another common query revolves around minimum pipe length requirements for slip-on installations; our experts advise on optimal practices to ensure proper welding and structural integrity.

Frequently Asked Questions (FAQs)

-

Q: What are the primary advantages of slip-on weld flanges over weld neck flanges?

A: Slip-on flanges are generally more cost-effective and easier to align during installation, requiring less precision in pipe cutting. They are ideal for lower pressure, moderate temperature applications. Weld neck flanges offer superior strength and are preferred for high-pressure, high-temperature, or critical services due to their butt-weld connection.

-

Q: Can slip-on weld flanges be used in corrosive environments?

A: Yes, provided they are manufactured from appropriate corrosion-resistant materials such as various grades of stainless steel (e.g., 304/304L, 316/316L) or specific alloy steels. Material selection is critical and should be based on the specific corrosive media and operating conditions.

-

Q: What inspection standards do your flanges meet?

A: Our flanges adhere to strict international standards including ASME B16.5, B16.47, EN, DIN, and JIS. We perform comprehensive quality checks, including dimensional inspection, material testing, and non-destructive testing (NDT) as required by project specifications.

References

- American Society of Mechanical Engineers. (ASME B16.5) Pipe Flanges and Flanged Fittings: NPS 1/2 Through NPS 24 Metric/Inch Standard.

- American Society for Testing and Materials. (ASTM A105/A105M) Standard Specification for Carbon Steel Forgings for Piping Applications.

- International Organization for Standardization. (ISO 9001) Quality Management Systems – Requirements.

- American Petroleum Institute. (API 6A) Specification for Wellhead and Christmas Tree Equipment.

- European Committee for Standardization. (EN 1092-1) Flanges and their joints – Circular flanges for pipes, valves, fittings and accessories, PN designated.

Real-World Impact: Case Studies and Client Success with Slip-On Weld Flanges

The practical effectiveness of slip on weld flanges is best illustrated through real-world application scenarios and positive client feedback. For instance, a leading petrochemical complex recently undertook a major expansion project involving numerous utility lines and non-critical process piping. The client opted for our standard carbon steel slip-on flanges (ASME B16.5, Class 150 RF) for their ease of installation and cost-efficiency. Our technical team provided detailed engineering support, ensuring optimal material selection and fit-up procedures. The project reported a 15% reduction in overall installation time compared to previous projects utilizing weld neck flanges, primarily due to the simplified alignment and welding process inherent to the slip-on design. This translated into significant labor cost savings and expedited project completion. Another compelling case involved a municipal water treatment facility upgrading its pump stations. The project required hundreds of stainless steel flange slip on welding units (ASTM A182 F316L) to resist corrosion from treated water. Our ability to supply custom-bored flanges to accommodate varying pipe schedules, coupled with a guaranteed rapid delivery schedule, was critical. The project manager noted that the consistency in flange dimensions and superior surface finish minimized gasket sealing issues, ensuring a leak-free system upon commissioning. Furthermore, a long-standing client in the pulp and paper industry, facing recurring issues with flange leakage in their steam lines, implemented our high-grade alloy steel slip-on flanges. Post-installation, the facility reported a dramatic decrease in steam leaks, leading to substantial energy savings and reduced maintenance downtime, validating the long-term reliability and robustness of our products even in challenging environments. These instances underscore how the correct application of these components, backed by robust manufacturing and technical support, delivers measurable operational benefits and enhanced system reliability for diverse industrial operations, solidifying our reputation as a trusted provider.

Ensuring Trust: FAQs, Quality Assurance, and Customer Support

Building and maintaining trust with B2B clients is paramount, and this extends beyond product quality to encompass comprehensive support and transparent practices. We prioritize clarity and reliability, offering detailed insights into our operations and commitments. Our quality assurance framework for slip on weld flanges is rigorous, commencing from the careful selection of raw materials, through meticulous in-process controls, to final product inspection. Every batch undergoes stringent testing, including material composition analysis, mechanical property tests (tensile strength, yield strength, hardness), and dimensional verification, ensuring full compliance with ASME, ANSI, and ISO standards. We provide full material traceability and comprehensive test certificates with every order. Our typical delivery cycle for standard flanges ranges from 2 to 4 weeks, with expedited options available for urgent requirements, while customized solutions may require slightly longer lead times depending on complexity. We stand by the quality of our products with a robust warranty policy, covering manufacturing defects for a specified period (e.g., 12-24 months from installation or 18-30 months from shipment, whichever comes first). Our dedicated customer support team is available to assist with technical queries, order tracking, and any post-delivery concerns, ensuring a seamless experience from inquiry to installation. We also maintain a comprehensive FAQ section to address common concerns proactively. For example, a frequently asked question is whether slip on weld neck flange types are always superior; the answer clarifies that while weld necks offer higher integrity for extreme conditions, slip-ons provide cost and installation advantages for appropriate applications. Another common query revolves around minimum pipe length requirements for slip-on installations; our experts advise on optimal practices to ensure proper welding and structural integrity.

Frequently Asked Questions (FAQs)

-

Q: What are the primary advantages of slip-on weld flanges over weld neck flanges?

A: Slip-on flanges are generally more cost-effective and easier to align during installation, requiring less precision in pipe cutting. They are ideal for lower pressure, moderate temperature applications. Weld neck flanges offer superior strength and are preferred for high-pressure, high-temperature, or critical services due to their butt-weld connection.

-

Q: Can slip-on weld flanges be used in corrosive environments?

A: Yes, provided they are manufactured from appropriate corrosion-resistant materials such as various grades of stainless steel (e.g., 304/304L, 316/316L) or specific alloy steels. Material selection is critical and should be based on the specific corrosive media and operating conditions.

-

Q: What inspection standards do your flanges meet?

A: Our flanges adhere to strict international standards including ASME B16.5, B16.47, EN, DIN, and JIS. We perform comprehensive quality checks, including dimensional inspection, material testing, and non-destructive testing (NDT) as required by project specifications.

References

- American Society of Mechanical Engineers. (ASME B16.5) Pipe Flanges and Flanged Fittings: NPS 1/2 Through NPS 24 Metric/Inch Standard.

- American Society for Testing and Materials. (ASTM A105/A105M) Standard Specification for Carbon Steel Forgings for Piping Applications.

- International Organization for Standardization. (ISO 9001) Quality Management Systems – Requirements.

- American Petroleum Institute. (API 6A) Specification for Wellhead and Christmas Tree Equipment.

- European Committee for Standardization. (EN 1092-1) Flanges and their joints – Circular flanges for pipes, valves, fittings and accessories, PN designated.

-

May. 27, 2025

May. 27, 2025Plastic pipe fittings, in particular, are witnessing substantial growth due to their cost-effectiveness and versatility.

-

Apr. 24, 2025

Apr. 24, 2025Jiuyuan Pipeline is excited to announce its participation in the upcoming 2025 Wire / Tube with Metal & Steel KSA exhibition, scheduled from May 5th to May 7th, 2025.

If you are interested in our products, you can choose to leave your information here, and we will be in touch with you shortly.