- Albanian

- Arabic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bulgarian

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Finnish

- French

- German

- Greek

- Hebrew

- Hungarian

- Indonesian

- irish

- Italian

- Japanese

- Khmer

- Korean

- Kyrgyz

- Lao

- Latin

- Lithuanian

- Malay

- Myanmar

- Norwegian

- Persian

- Polish

- Portuguese

- Romanian

- Russian

- Serbian

- Slovak

- Slovenian

- Spanish

- Swedish

- Tagalog

- Thai

- Turkish

- Turkmen

- Uzbek

- Vietnamese

- Zulu

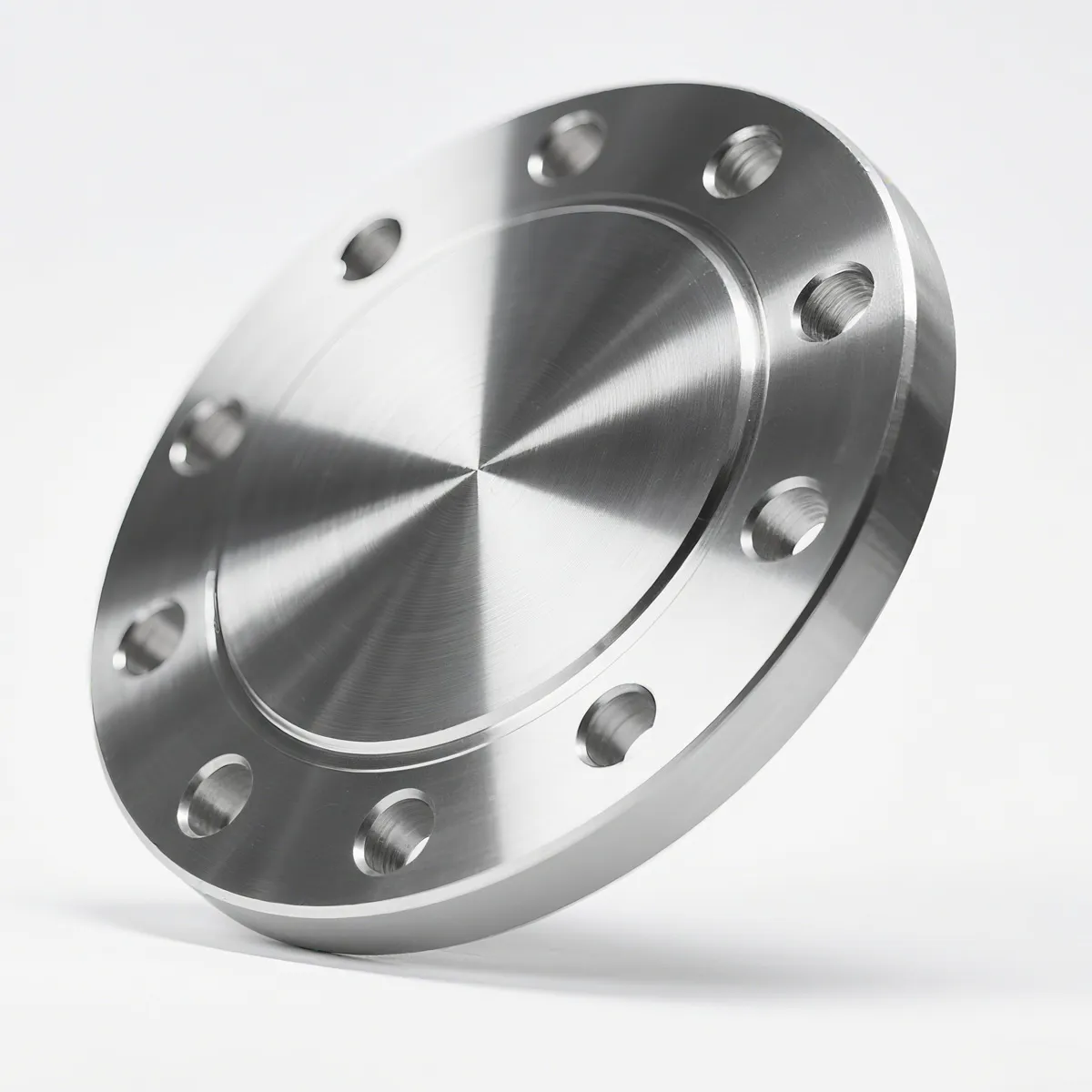

Blind flanges are essential components in industrial piping systems, designed to block off pipeline openings, valves, or pressure vessels. These solid disks provide a secure, leak-proof seal while allowing for future access, making them indispensable in industries such as oil and gas, petrochemicals, and power generation. This article delves into the Blind Flange product, exploring its technical specifications, applications, and the expertise of its manufacturer, Hebei Jiuyuan Pipeline Manufacturing Co., Ltd..

Product Overview

The Blind Flange is a critical component in pipeline systems, engineered to create a tight seal without the need for a gasket. Unlike other flanges, it lacks a central hole, making it ideal for sealing ends of pipelines or pressure vessels. This product is available in a wide range of materials, including carbon steel, stainless steel, and alloy steel, ensuring compatibility with diverse industrial environments. The specifications include pressure ratings from PN6 to PN40 and Class 150 to Class 2500, with nominal diameters ranging from DN10 to DN2000 (½ inch to 24 inches). The product adheres to international standards such as ASME, EN, JIS, DIN, BS, KS, GOST, and SABS, ensuring global compatibility and reliability.

Figure 1: Blind Flange Types - Explore the variety of blind flange designs available for different applications.

Key Features and Advantages

- Material Versatility: Available in carbon steel (ASTM A105, P235GH, P245GH, etc.), stainless steel (ASTM A182, 304, 306), and alloy steel, ensuring durability in corrosive or high-temperature environments.

- Compliance with Global Standards: Adheres to ASME, EN, JIS, DIN, BS, KS, GOST, and SABS standards, guaranteeing interoperability across international projects.

- Surface Coating Options: Options include black paint, galvanization, grease, and epoxy paint, enhancing corrosion resistance and longevity.

- Easy Installation and Removal: Designed for straightforward installation, allowing for frequent maintenance or system modifications without compromising integrity.

- High-Pressure Resistance: Suitable for low-pressure applications in noncorrosive environments, with robust construction to withstand operational stresses.

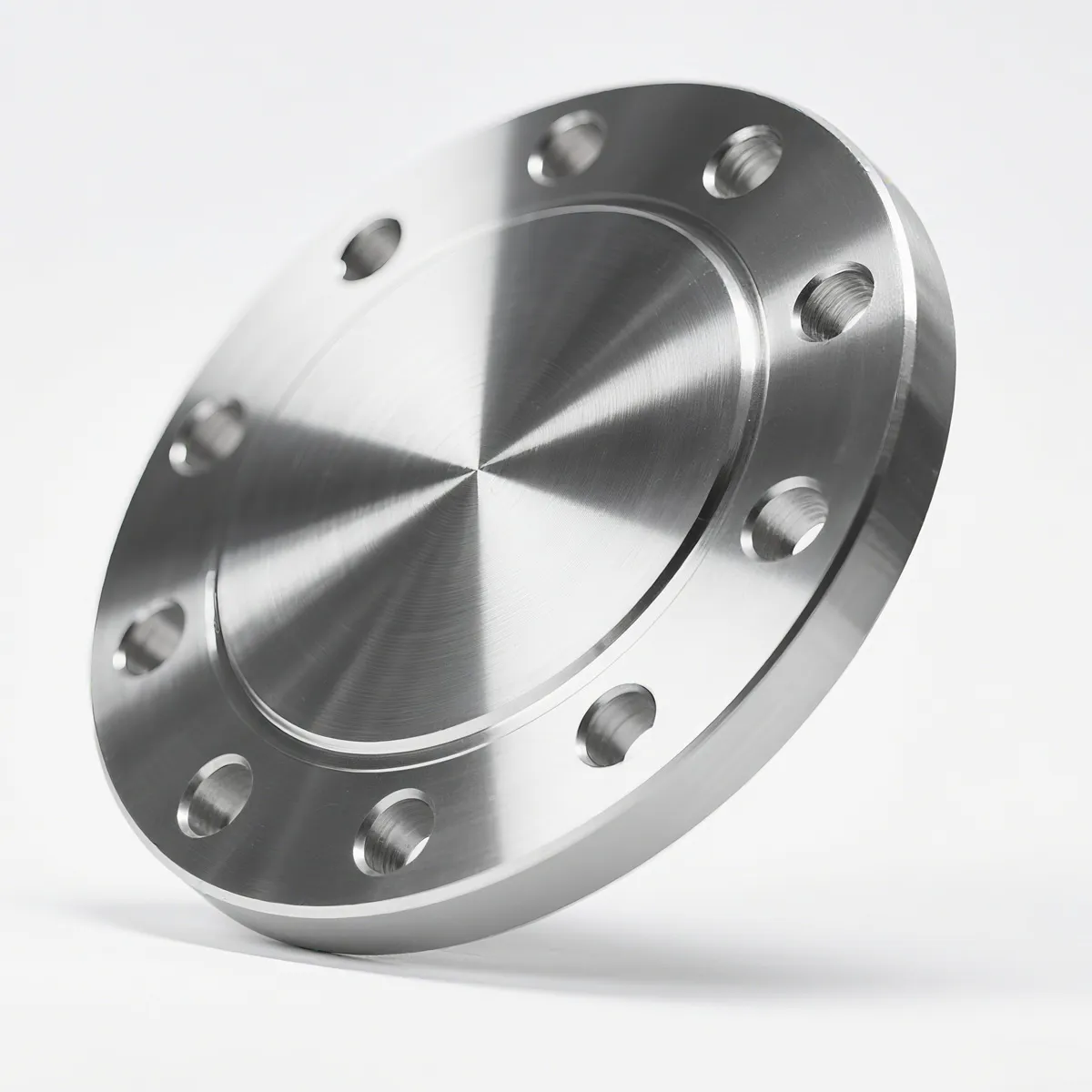

Figure 2: Blind Flange Applications - Discover how blind flanges are used in critical industrial systems.

Technical Specifications

| Parameter | Details |

|---|---|

| Pressure Rating | PN6 - PN40 / Class 150 - Class 2500 |

| Size Range | DN10 - DN2000 / ½" - 24" / 12" - 60" |

| Materials | Carbon Steel (ASTM A105, P235GH, P245GH, P250GH, P265GH, ST37-2), Stainless Steel (ASTM A182, 304, 306) |

| Standards | ASME, EN, JIS, DIN, BS, KS, GOST, SABS, ATK |

| Surface Coating | Black paint, Galvanize, Grease, Epoxy paint |

Applications in Industrial Systems

Blind flanges are widely used in industries where pipeline integrity and accessibility are critical. Their primary applications include:

- Pipeline Sealing: Blocking the end of pipelines during maintenance or system shutdowns.

- Pressure Testing: Ensuring leak-proof connections during pipeline pressure tests.

- Future Expansion: Providing a removable seal for future system modifications or expansions.

- Valve and Vessel Isolation: Creating a secure barrier for valves or pressure vessels during maintenance.

- Corrosion Protection: Surface coatings like epoxy paint and galvanization protect against environmental degradation.

Figure 3: Blind Flange Installation - Learn how to properly install a blind flange for optimal performance.

Installation Guide

Proper installation of a blind flange ensures a secure seal and long-term reliability. Follow these steps:

- Prepare the Flange Faces: Clean the mating surfaces and gasket area to remove debris or contaminants.

- Select the Gasket: Choose a gasket compatible with the fluid type and pressure conditions (sold separately).

- Align and Bolt: Match the bolt holes of the blind flange with the mating flange and insert bolts. Tighten in a crisscross pattern for even pressure distribution.

- Apply Torque: Use a torque wrench to apply the recommended torque values, ensuring a leak-proof connection.

- Pressure Test: Conduct a pressure test to verify the seal's integrity before system operation.

Company Background: Hebei Jiuyuan Pipeline Manufacturing Co., Ltd.

Hebei Jiuyuan Pipeline Manufacturing Co., Ltd. is a leading manufacturer of industrial piping components, specializing in blind flanges, valves, and fittings. With a commitment to quality and innovation, the company adheres to international standards and provides solutions for diverse industrial applications. Their expertise in material selection, precision manufacturing, and surface treatment ensures that their products meet the highest performance and durability requirements.

Why Choose This Blind Flange?

The Blind Flange from Hebei Jiuyuan offers a combination of robust design, material versatility, and compliance with global standards. Its key advantages include:

- Reliable Sealing: Ensures leak-proof connections in low-pressure environments.

- Easy Maintenance: Facilitates quick installation and removal for routine inspections or repairs.

- Global Compatibility: Adheres to ASME, EN, JIS, and other international standards.

- Corrosion Resistance: Surface coatings like epoxy paint and galvanization extend service life in harsh conditions.

Conclusion

The Blind Flange is a critical component in industrial piping systems, offering a secure, removable seal for pipelines, valves, and pressure vessels. With its robust construction, compliance with international standards, and ease of installation, it is an ideal solution for industries requiring frequent maintenance or future expansion. Hebei Jiuyuan Pipeline Manufacturing Co., Ltd. continues to deliver high-quality products that meet the evolving demands of modern industrial applications.

References

NIST (National Institute of Standards and Technology) plays a pivotal role in establishing standards for industrial components, ensuring accuracy and reliability in measurements and materials. While the specific content from the NIST website was not accessible, their work in defining standards for materials and manufacturing processes directly supports the quality and compliance of products like the Blind Flange. For more information, visit the NIST official website.

Keywords: Blind Flange, Blind Flange Types, Blind Flanges Types, Types of Blind Flange.

-

Apr. 28, 2025

Apr. 28, 2025From April 15 to April 19, 2025, our company proudly participated in the renowned Canton Fair held in Guangzhou, China.

-

May. 27, 2025

May. 27, 2025Plastic pipe fittings, in particular, are witnessing substantial growth due to their cost-effectiveness and versatility.

If you are interested in our products, you can choose to leave your information here, and we will be in touch with you shortly.