- Albanian

- Arabic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bulgarian

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Finnish

- French

- German

- Greek

- Hebrew

- Hungarian

- Indonesian

- irish

- Italian

- Japanese

- Khmer

- Korean

- Kyrgyz

- Lao

- Latin

- Lithuanian

- Malay

- Myanmar

- Norwegian

- Persian

- Polish

- Portuguese

- Romanian

- Russian

- Serbian

- Slovak

- Slovenian

- Spanish

- Swedish

- Tagalog

- Thai

- Turkish

- Turkmen

- Uzbek

- Vietnamese

- Zulu

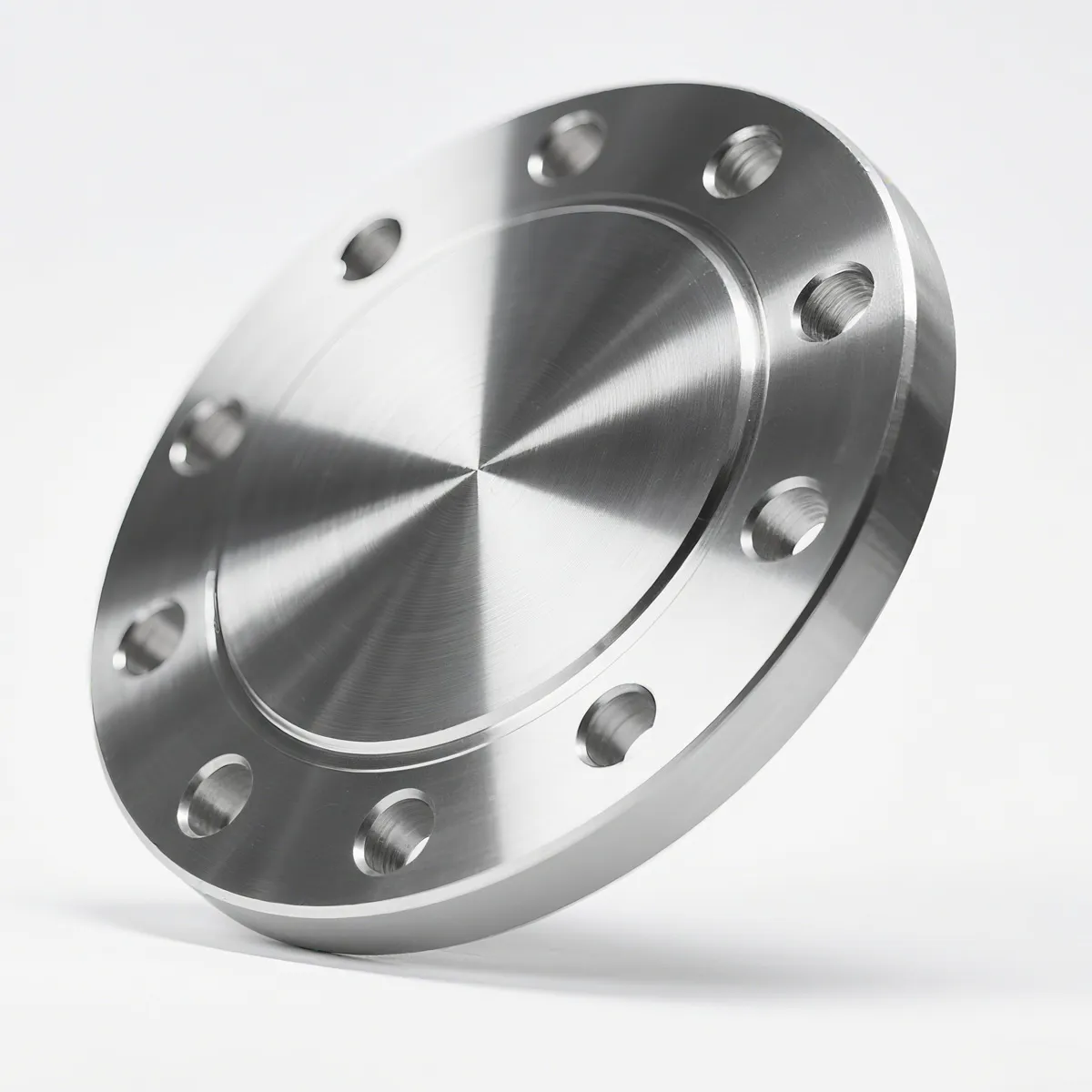

Blind Flange Overview: A blind flange is a solid disk used to seal the end of a piping system, valve, or pressure vessel. Its design allows for easy installation and removal, making it ideal for systems requiring frequent maintenance or future expansion. This guide explores the technical specifications, applications, and industry relevance of blind flanges, with insights from HEBEI JIUYUAN PIPELINE MANUFACTURING CO.,LTD.

Product Features and Technical Specifications

Blind flanges are engineered to provide secure, leak-proof seals in industrial piping systems. Their robust construction and compliance with international standards make them indispensable in high-pressure environments. Below is a detailed breakdown of their key features and specifications:

| Parameter | Details |

|---|---|

| Pressure Ratings (PN/CLASS) | PN6 - PN40 / Class150 - Class2500 |

| Diameter (DN/INCH) | DN10 - DN2000 / ½In - 24In / S.A 12In - 60In |

| Materials | Carbon Steel (ASTM A105, P235GH, P245GH, P250GH, P265GH, ST37-2), Stainless Steel (ASTM A182, 304, 306) |

| Standards Compliance | ASME, EN, JIS, DIN, BS, KS, GOST, SABS, ATK |

| Surface Coating | Black paint, Galvanize, Grease, Epoxy paint |

Material and Design Advantages: The use of high-quality materials like carbon steel and stainless steel ensures durability and resistance to corrosion. Blind flanges are available in multiple pressure ratings and sizes, catering to diverse industrial needs. Their compatibility with international standards (e.g., NIST standards) guarantees interoperability and reliability in global applications.

Applications in Industrial Systems

Blind flanges are critical components in piping systems where temporary or permanent sealing is required. They are commonly used in the following scenarios:

- System Expansion: Providing access points for future pipeline extensions or modifications.

- Maintenance and Inspection: Allowing easy removal for cleaning, testing, or component replacement.

- High-Pressure Environments: Ensuring secure seals in oil and gas, petrochemical, and power generation sectors.

Key Applications: From HEBEI JIUYUAN PIPELINE MANUFACTURING CO.,LTD's perspective, blind flanges are essential in industries such as oil and gas, chemical processing, power generation, and water treatment. Their ability to withstand extreme conditions makes them ideal for critical infrastructure.

Installation and Maintenance Best Practices

Proper installation is crucial to ensure the effectiveness of blind flanges. Follow these steps for optimal performance:

- Preparation: Clean flange faces and gaskets to remove debris. Use a gasket compatible with the system's fluid and pressure (e.g., NIST-certified materials).

- Alignment: Match bolt holes and insert bolts. Ensure the correct grade and number of bolts as per the flange rating.

- Tightening: Use a torque wrench to apply even pressure in a crisscross pattern. Refer to manufacturer guidelines for torque specifications.

- Testing: Conduct pressure tests post-installation to verify leak-proof seals.

Regular maintenance, including inspection for wear and corrosion, is recommended to prolong the lifespan of blind flanges.

Company Background: HEBEI JIUYUAN PIPELINE MANUFACTURING CO.,LTD

HEBEI JIUYUAN PIPELINE MANUFACTURING CO.,LTD is a leading manufacturer of industrial piping solutions, specializing in blind flanges and related components. With a focus on quality and innovation, the company adheres to international standards to deliver reliable products for global markets. Their expertise in materials science and engineering ensures that their blind flanges meet the rigorous demands of modern industrial systems.

Conclusion

Blind flanges are vital for ensuring the integrity and flexibility of piping systems. Their design, materials, and compliance with industry standards make them indispensable in sectors requiring high-performance sealing solutions. For more information on blind flange types and their applications, visit HEBEI JIUYUAN PIPELINE MANUFACTURING CO.,LTD.

References

1. National Institute of Standards and Technology (NIST): https://www.nist.gov/standards-and-measurements

2. Industry Standards Compliance: ASME, EN, JIS, DIN, BS, KS, GOST, SABS, ATK.

-

May. 27, 2025

May. 27, 2025Plastic pipe fittings, in particular, are witnessing substantial growth due to their cost-effectiveness and versatility.

-

Apr. 28, 2025

Apr. 28, 2025From April 15 to April 19, 2025, our company proudly participated in the renowned Canton Fair held in Guangzhou, China.

If you are interested in our products, you can choose to leave your information here, and we will be in touch with you shortly.