- Albanian

- Arabic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bulgarian

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Finnish

- French

- German

- Greek

- Hebrew

- Hungarian

- Indonesian

- irish

- Italian

- Japanese

- Khmer

- Korean

- Kyrgyz

- Lao

- Latin

- Lithuanian

- Malay

- Myanmar

- Norwegian

- Persian

- Polish

- Portuguese

- Romanian

- Russian

- Serbian

- Slovak

- Slovenian

- Spanish

- Swedish

- Tagalog

- Thai

- Turkish

- Turkmen

- Uzbek

- Vietnamese

- Zulu

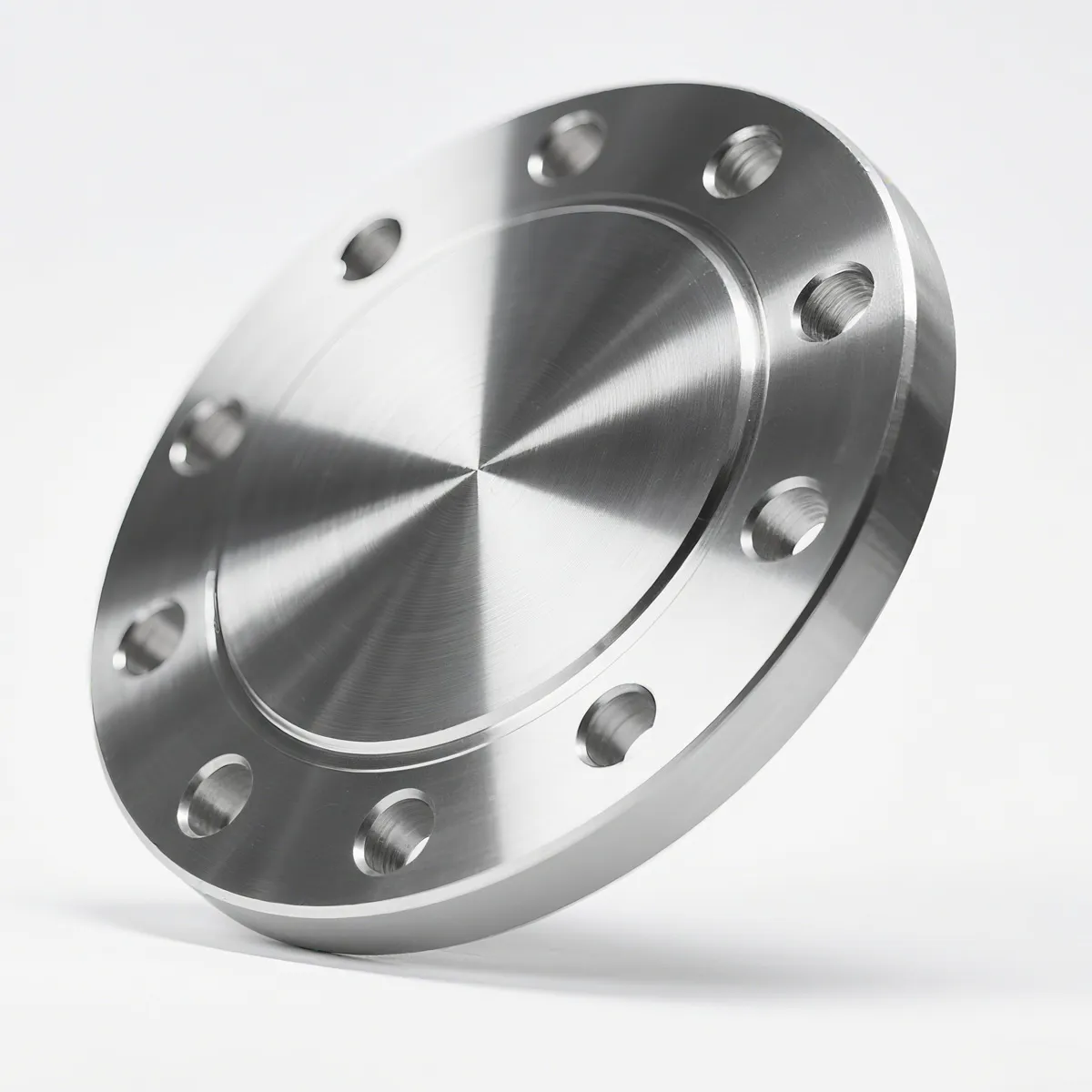

Introduction to Blind Flanges

A blind flange is a critical component in piping systems, designed to seal the end of a pipeline, valve, or pressure vessel. Unlike other flanges, it lacks a central hole, making it ideal for blocking fluid or gas flow. These solid disks are engineered for ease of installation and removal, catering to applications requiring frequent maintenance or future expansion. This article explores the features, technical specifications, applications, and industry relevance of blind flanges, with insights into their manufacturing and compliance with international standards.

Product Features and Advantages

Blind flanges are manufactured from a variety of materials, including carbon steel, stainless steel, and alloy steel, ensuring exceptional strength, durability, and resistance to pressure and temperature. Their design allows for secure sealing, making them indispensable in industries such as oil and gas, petrochemicals, power generation, and water treatment. Key advantages include:

- Easy Installation and Removal: Blind flanges are bolted onto matching flanges, enabling quick access for maintenance or system modifications.

- Compatibility with International Standards: Available in pressure ratings such as ANSI/ASME, DIN, JIS, and more, ensuring seamless integration with global piping systems.

- Corrosion Resistance: Surface coatings like black paint, galvanization, and epoxy paint enhance longevity in noncorrosive environments.

- Customization: Manufactured in sizes ranging from DN10 to DN2000 (½ inch to 24 inches), catering to diverse industrial needs.

Technical Specifications

| Parameter | Details |

|---|---|

| Pressure Ratings (PN/CLASS) | PN6 - PN40 / Class150 - Class2500 |

| Size (DN/INCH) | DN10 - DN2000 / ½In - 24In / S.A 12In - 60In |

| Materials (MAR) | Carbon Steel (ASTM A105, P235GH, P245GH, P250GH, P265GH, ST37-2) / Stainless Steel (ASTM A182, 304, 306) |

| Standards (STD) | ASME, EN, JIS, DIN, BS, KS, GOST, SABS, ATK |

| Surface Coating | Black paint, Galvanize, Grease, Epoxy paint |

Applications in Industrial Systems

Blind flanges are widely used in piping systems to create access points, facilitate system expansion, and ensure operational safety. Their applications span multiple industries:

- Oil and Gas: Sealing pipeline ends during maintenance or future modifications.

- Chemical Processing: Providing leak-proof barriers in high-pressure environments.

- Power Generation: Ensuring integrity of steam and water systems.

- Water Treatment: Blocking flow for inspection or repair of filtration units.

- Shipbuilding: Securing piping systems in marine environments.

Installation and Maintenance

Proper installation of a blind flange ensures a secure, leak-proof connection. The process involves:

- Preparation: Clean flange faces and gaskets to remove debris.

- Gasket Selection: Use a gasket compatible with the system's fluid and pressure.

- Bolt Alignment: Align bolt holes and insert bolts in a crisscross pattern for even pressure.

- Torque Application: Use a torque wrench to apply specified torque values.

- Pressure Testing: Verify the seal by testing the system for leaks.

Maintenance involves periodic inspection for wear and corrosion, with reapplication of coatings as needed. The ease of removal makes blind flanges ideal for systems requiring frequent access.

Company Background: Hebei Jiuyuan Pipeline Manufacturing Co., Ltd.

Founded in China, HEBEI JIUYUAN PIPELINE MANUFACTURING CO.,LTD specializes in producing high-quality piping components, including blind flanges. With a focus on precision engineering and compliance with international standards, the company serves global clients in energy, manufacturing, and infrastructure sectors. Their commitment to innovation and quality ensures reliable solutions for complex industrial applications.

Industry Standards and Compliance

Blind flanges are designed to meet rigorous standards set by organizations like NIST (National Institute of Standards and Technology), which plays a pivotal role in advancing measurement science. While the provided NIST content is limited, their work in metrology ensures the accuracy of standards such as ASME, DIN, and JIS, which are critical for the reliability of piping systems. Compliance with these standards guarantees interoperability and safety in industrial environments.

Conclusion

Blind flanges are essential components in modern piping systems, offering versatility, durability, and compliance with global standards. Their role in ensuring system integrity and operational safety cannot be overstated. For manufacturers and engineers, selecting the right blind flange involves understanding material properties, pressure ratings, and industry-specific requirements. By partnering with reputable suppliers like Hebei Jiuyuan Pipeline Manufacturing Co., Ltd., industries can leverage cutting-edge solutions that meet the demands of today's complex infrastructure.

References

NIST (National Institute of Standards and Technology): https://www.nist.gov/

HEBEI JIUYUAN PIPELINE MANUFACTURING CO.,LTD: https://www.hbjypipeline.com/

-

Apr. 28, 2025

Apr. 28, 2025From April 15 to April 19, 2025, our company proudly participated in the renowned Canton Fair held in Guangzhou, China.

-

Apr. 24, 2025

Apr. 24, 2025Jiuyuan Pipeline is excited to announce its participation in the upcoming 2025 Wire / Tube with Metal & Steel KSA exhibition, scheduled from May 5th to May 7th, 2025.

If you are interested in our products, you can choose to leave your information here, and we will be in touch with you shortly.