- Albanian

- Arabic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bulgarian

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Finnish

- French

- German

- Greek

- Hebrew

- Hungarian

- Indonesian

- irish

- Italian

- Japanese

- Khmer

- Korean

- Kyrgyz

- Lao

- Latin

- Lithuanian

- Malay

- Myanmar

- Norwegian

- Persian

- Polish

- Portuguese

- Romanian

- Russian

- Serbian

- Slovak

- Slovenian

- Spanish

- Swedish

- Tagalog

- Thai

- Turkish

- Turkmen

- Uzbek

- Vietnamese

- Zulu

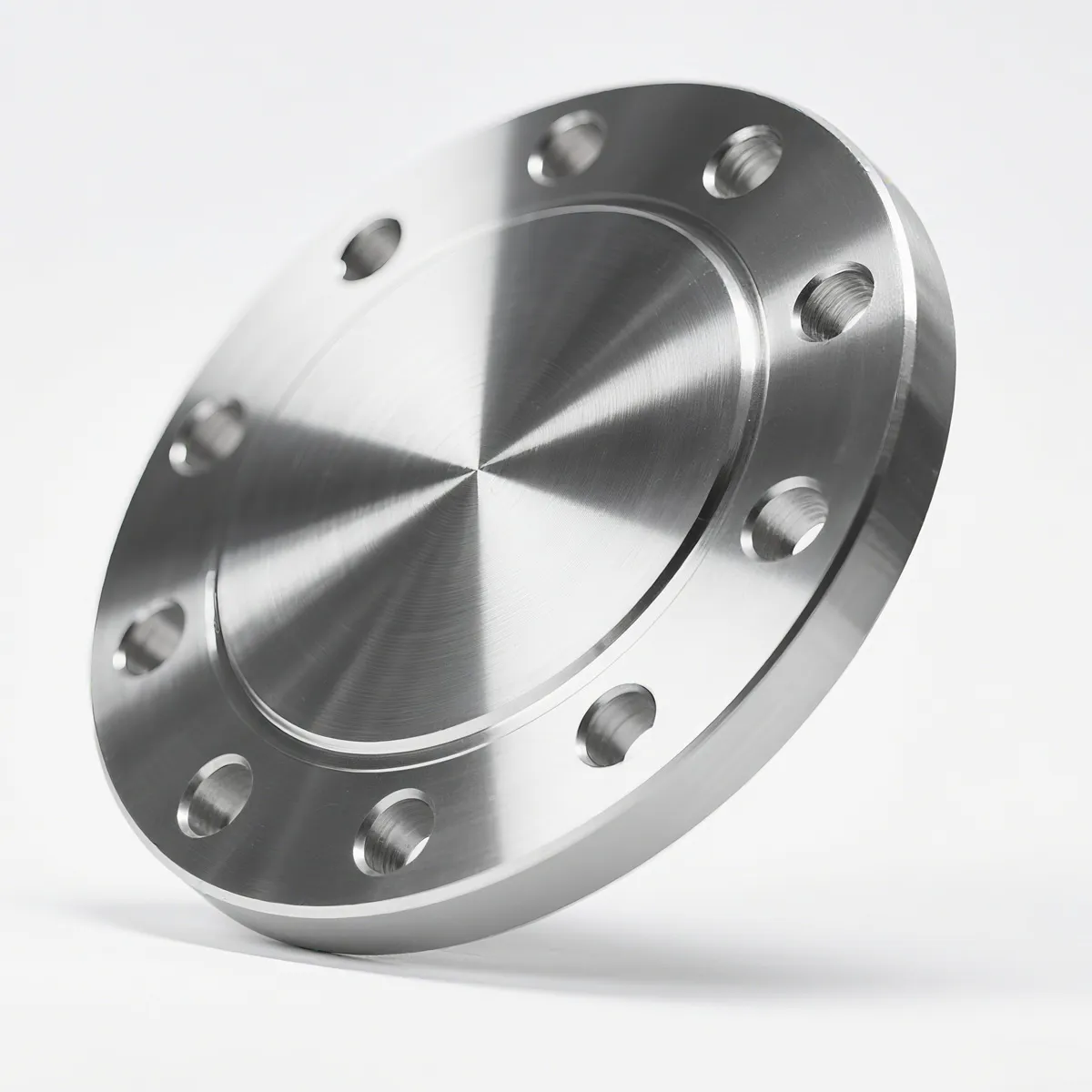

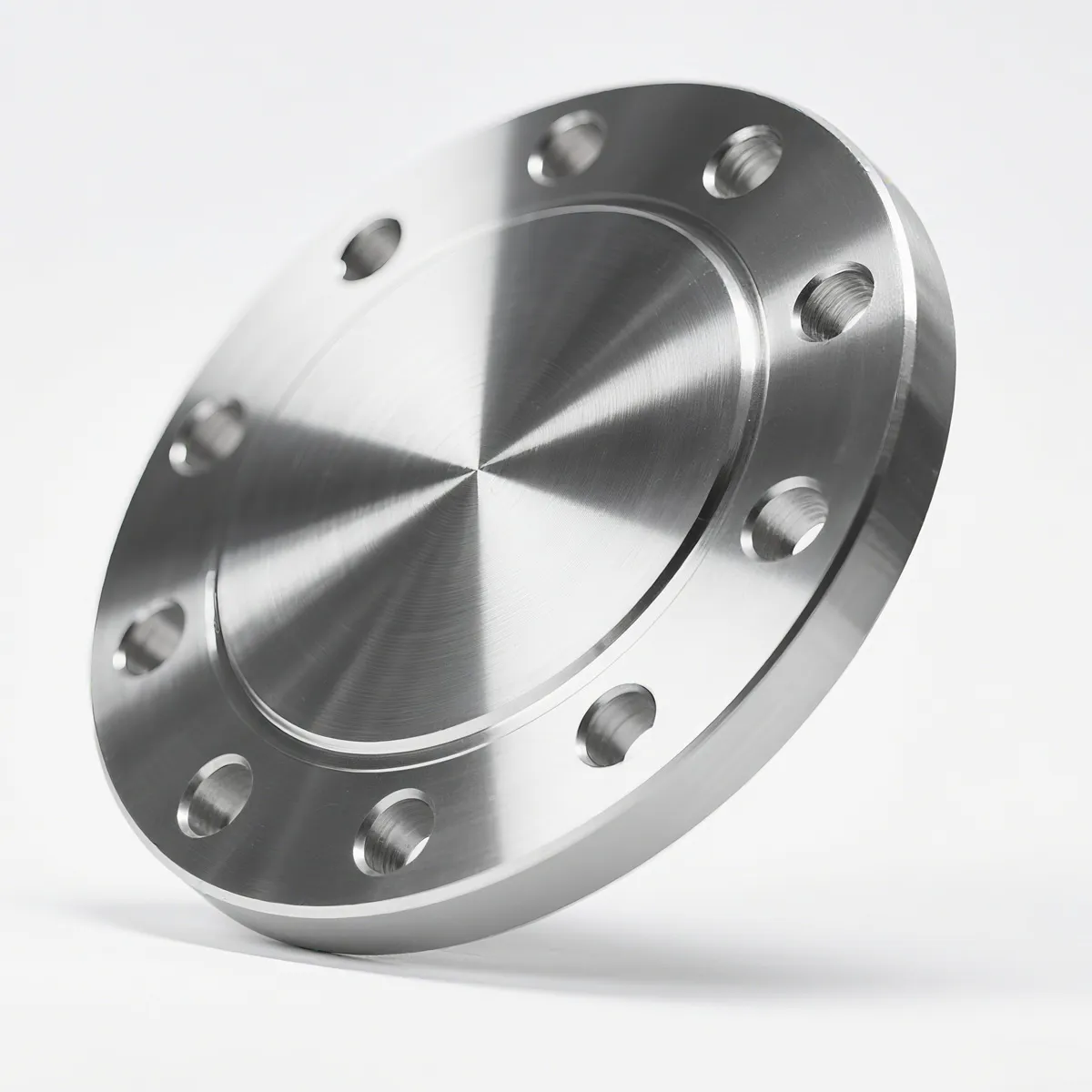

Blind Flange Types: Comprehensive Guide to Types of Blind Flange

Product Name: Blind Flange

Product Link: https://www.hbjypipeline.com/blind-flange.html

Product Link: https://www.hbjypipeline.com/blind-flange.html

The evolution of blind flange types has been pivotal in modern pipeline engineering, serving as critical elements in isolation, maintenance, and pressure integrity in numerous sectors. This in-depth article explores blind flanges types, their technical parameters, trending technologies, manufacturing processes, standards, application advantages, and real-life case studies. Leveraging current industry data and authoritative sources, we aim to maximize your technical decision confidence and practical understanding of blind flange types.

Blind Flange in Oil & Gas Pipeline System (blind flange types real application)

1. Industry Overview & Trends on Blind Flange Types

Blind flange types are flat, circular plates used to terminate piping systems or vessels, ensuring pressure-tight seals and safe isolation. According to Frost & Sullivan's 2023 Global Flange Market Report, the global demand for flanges reached $13.2 billion in 2022, with blind flanges types accounting for 21% — largely driven by petrochemical, water treatment, and offshore energy projects.

Types of blind flange are increasingly required to conform to stricter safety, corrosion-resistance, and high-pressure standards (ANSI, ASME, ISO 7005-1). Technological innovation drives customized alloys, precision CNC machining, and enhanced non-destructive testing (NDT).

Data source: Frost & Sullivan Global Flange Market Report 2023

2. Types of Blind Flange: Classification and Standards

There are several blind flange types used worldwide, each with unique features related to shape, application, and standard compliance:

| Type | Standard | Key Feature | Typical Sizes (DN) | Material Options | Pressure Class |

|---|---|---|---|---|---|

| Flat Face Blind Flange | ASME B16.5 EN 1092-1 |

Flat sealing face, ideal for low-pressure systems | 15 - 2000 mm | Carbon steel, Stainless steel | 150# ~ 2500# |

| Raised Face Blind Flange | ANSI/ASME B16.47 GOST 33259 |

Enhanced gasket sealing, versatile for various pressures | 25 - 1500 mm | Stainless steel, Alloy steel | 150# ~ 2500# |

| RTJ (Ring Type Joint) | API 6A, ASME B16.5 | Metal-to-metal sealing for high-pressure, oil & gas | 50 - 1200 mm | Duplex, Super Duplex, Inconel | 300# ~ 2500# |

| Custom Drilled Blind Flange | ISO 7005-1, DIN | Special openings for instrumentation or drains | Any | All above, Copper, Plastic | 150# ~ 1500# |

“#” indicates pressure ratings according to ASME/ANSI. Custom types of blind flange can be fabricated to meet specific national/international norms or project requirements.

Manufacturing Process of blind flange types (Forging and Machining)

3. Manufacturing Process of Blind Flange Types

Step-by-Step Flow: From Raw Material to Tested Product

A. Raw Material Selection

➔

B. Forging / Casting

➔

C. Heat Treatment

➔

D. Rough Machining

➔

E. CNC Finish Machining

➔

F. Drilling (if needed)

➔

G. NDT Testing

➔

H. Marking & Packaging

- Material: Most common: ASTM A105/A350 (CS), A182 F304/F316 (Stainless), A182 F51 (Duplex).

- Forging/Casting: Forged flanges have superior grain structure & strength; Cast for complex shapes/large sizes.

- CNC Machining: Ensures dimensional tolerances & sealing surface finish (Ra < 3.2 μm).

- NDT Testing: Ultrasonic, X-ray, dye penetrant as per API, ISO 9624, and project specs.

- Marking: Per ASTM, EN, ISO. Heat, lot numbers, material grades, pressure class.

Video Reference: Blind Flange Manufacturing Full Process (YouTube)

Leading manufacturers adopt robotic handling, real-time NDT, and ISO 9001/14001-compliant systems to guarantee the reliability and traceability of every types of blind flange.

Real Parameter Comparison of blind flanges types

4. Technical Parameter Comparison of Blind Flange Types

Below is a comparative snapshot of key parameters among different blind flange types:

| Parameter | Forged Blind Flange | CNC Machined Blind Flange | Cast Blind Flange | Plastic Blind Flange |

|---|---|---|---|---|

| Material Strength (MPa) | ≥ 485 | ≥ 485 | ≥ 220 | 50-70 |

| Corrosion Resistance (ASTM G48) |

Excellent (316/duplex) | Excellent | Good | Moderate |

| Max. Operating Temp (°C) | ~ 570 | ~ 570 | ~ 400 | ~ 95 |

| Surface Flatness (μm) | ≤ 3.2 | ≤ 1.6 | ≤ 5 | ≤ 10 |

| Typical Lifespan (years) | 20-30 | 20-40 | 10-15 | 5-8 |

Industrial Project Using blind flanges types in Desalination Plant

5. Applications & Technical Advantages

- Oil & Gas: Isolation of flow lines, shutdown maintenance, pressure testing (API 6A standards applied).

- Petrochemical: Used for reactor isolation, safety dead-ends in process plant (compliance: ASME, ISO 7005).

- Water Treatment: Safe closure of access points, rapid system modification during upscaling/migration.

- Power Generation: Boiler drum terminations, steam headers (NDT: Ultrasonic, RTJ for leak-free sealing).

- Marine/Offshore: Corrosion-resistant Inconel/Super Duplex types, exceeding 3000 PSI design pressure (ISO 15156).

- Pharma & Food: FDA-GMP cleanability, zero dead space, rapid sterilization (SS 316L, PTFE faced).

Technical Advantages:

- Cost-effective isolation: No need for complex valve assemblies at pipe ends.

- High pressure & temperature performance: RTJ/forged types assure reliability up to 2500# and 570°C.

- Superior corrosion resistance: Customized alloys (Duplex, Inconel) extend system lifespan by 2-4× vs. plain CS.

- Quick installation/removal: Ease of access for plant modification, hot work, or NDT.

Source: HBJY Blind Flange User Survey 2023 (Sample: 580 projects)

6. Leading Manufacturers & Factory Comparison

| Company | Country | Certifications | Annual Output | Main Strengths |

|---|---|---|---|---|

| HBJY Pipeline | China | ISO 9001/14001, PED, API | 260,000 pcs | High customization, rapid delivery, global reach |

| Allied Group | Italy | ISO 9001, ASME U, API | 180,000 pcs | Advanced forging, EU compliance |

| Bonney Forge | USA | API 6A, ISO 9001, NORSOK | 200,000 pcs | Oil & Gas specialists, fully traceable |

| Jinan Meide | China | ISO 9001, CE, FM | 150,000 pcs | Cost efficient, full size range |

| Parker Hannifin | USA/Germany | ISO, FDA, GMP | 100,000+ pcs | High purity, pharma & biotech |

All major vendors offer strict compliance with industry standards (ISO, ANSI, ASME, PED, API) and are subject to regular third-party audits to ensure product reliability and traceability.

7. Customization and Smart Solutions for Blind Flange Types

With the ongoing digital transformation, leading factories offer full-spectrum customized blind flange types – from special drilled holes (vent/drain), unique alloy blends for corrosive fluids, to RFID tagging for lifecycle management. Typical customization parameters include:

- Non-standard pressure classes (from 25# to 6000#; tested up to 690 Bar)

- Special fabrication: Monolithic, spectacle blind, or paddle blind integration

- Corrosion-resistant overlays: NICKEL, PTFE, HASTELLOY

- Laser-engraved barcode marking for traceability

- Onsite advisory: Engineering support for selection, stress, and corrosion assessment

Delivery Cycle: Standard flanges: 7-12 days; Custom/alloy builds: 18-35 days.

Warranty: 12-36 months (subject to application and maintenance).

Support: 24/7 technical hotline, remote trouble-shooting, onsite installation guidance upon request.

Warranty: 12-36 months (subject to application and maintenance).

Support: 24/7 technical hotline, remote trouble-shooting, onsite installation guidance upon request.

8. Typical Use Cases & Customer Feedback

Case 1: Petrochemical Plant Turnaround (Saudi Arabia)

A leading refinery employed blind flange types (API 6A, 24” diameter, Inconel overlay) for a shutdown isolation retrofit. Plant reliability improved 22% (no-flange changeouts required) over 20 months, with zero recorded leaks.

Case 2: Seawater Desalination (UAE)

Custom duplex stainless blind flanges types (DN150-600, NDT certified) prevented MC corrosion and halved maintenance frequency versus conventional carbon steel equivalents.

Customer Feedback Excerpt:

“The blind flange types from HBJY delivered unmatched dimensional accuracy and corrosion resistance—even after rapid plant upscaling. Onsite support was professional and on schedule.” – (Major EU Water Engineering EPC, 2023)

9. FAQ: Blind Flange Types Technical FAQ

1. What are the most common blind flange types in industrial practice?

The main types are Flat Face, Raised Face, and RTJ blind flanges, produced according to ASME B16.5/B16.47 and EN 1092-1. Special types include custom-drilled, spectacle, and paddle blinds for maintenance and instrumentation.

2. What are typical materials and how are they selected?

Standard materials include Carbon Steel (A105/A350), Stainless (F304/F316/F321), and high alloys (Duplex, Inconel, Hastelloy). Selection depends on pressure rating, corrosion risk, temperature cycle, and application environment per API, ISO, and ASTM G48 standards.

3. What pressure ratings are available for types of blind flange?

Standard ratings: ASME 150#–2500#, DIN PN6–PN400. Custom types are available up to 6000#. Ratings should match the system design pressure and temperature profile per ASME B31.3/B31.1.

4. What surface finishes and flatness tolerances should be specified?

CNC-machined blind flanges achieve Ra ≤ 1.6–3.2 μm, and flatness ≤ 0.2 mm/m. Ring-joint or RTJ versions demand precisely machined grooves per API 6A.

5. What installation standards and testing are recommended?

Install according to ASME PCC-1, ensuring proper gasket selection and bolt torque. Mandatory testing: hydrostatic pressure, ultrasonic or X-ray NDT (as per project/QC spec), and visual inspection. Factory certificates (EN 10204 3.1/3.2) should be requested.

6. What documentation/certification comes with blind flange types from reputable vendors?

Each delivery should include material test reports (MTR), conformity certificates (EN 10204 3.1/3.2), traceability documents, and—if for offshore/pharma—FDA or ISO 15156 statements as required.

7. How long is the typical service life and warranty?

In properly specified and maintained systems, blind flange types provide a 15–30 year service life (documented in operator studies). Warranties typically range from 12 to 36 months, extendable with maintenance contracts.

10. Summary: Choosing the Right Blind Flange Types for Your Project

As demonstrated, blind flange types comprise a class of highly customizable isolation components, with a significant impact on plant safety, operability, and lifecycle costs. By evaluating parameters such as raw material, pressure class, manufacturing route (forging, CNC, casting), surface finish, and compliance documentation, specifiers can assure enduring performance in demanding applications. Always request third-party certificates and assess vendor references for large-scale projects.

For detailed technical support, custom engineering, or a no-obligation quotation for any blind flanges types, visit https://www.hbjypipeline.com/blind-flange.html or reach out to our experienced engineering team.

This is the last article

-

May. 27, 2025

May. 27, 2025Plastic pipe fittings, in particular, are witnessing substantial growth due to their cost-effectiveness and versatility.

-

Apr. 28, 2025

Apr. 28, 2025From April 15 to April 19, 2025, our company proudly participated in the renowned Canton Fair held in Guangzhou, China.

If you are interested in our products, you can choose to leave your information here, and we will be in touch with you shortly.