- Albanian

- Arabic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bulgarian

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Finnish

- French

- German

- Greek

- Hebrew

- Hungarian

- Indonesian

- irish

- Italian

- Japanese

- Khmer

- Korean

- Kyrgyz

- Lao

- Latin

- Lithuanian

- Malay

- Myanmar

- Norwegian

- Persian

- Polish

- Portuguese

- Romanian

- Russian

- Serbian

- Slovak

- Slovenian

- Spanish

- Swedish

- Tagalog

- Thai

- Turkish

- Turkmen

- Uzbek

- Vietnamese

- Zulu

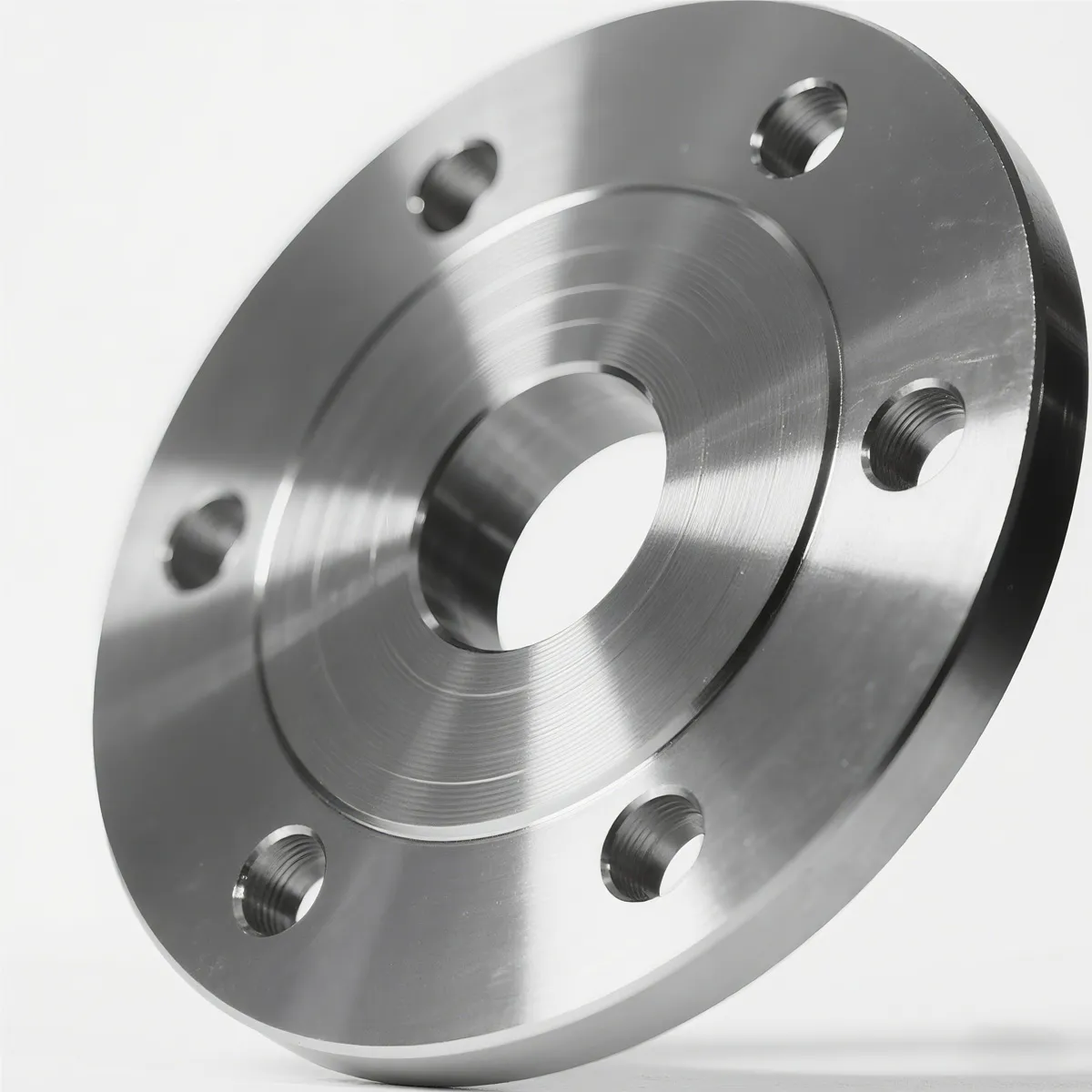

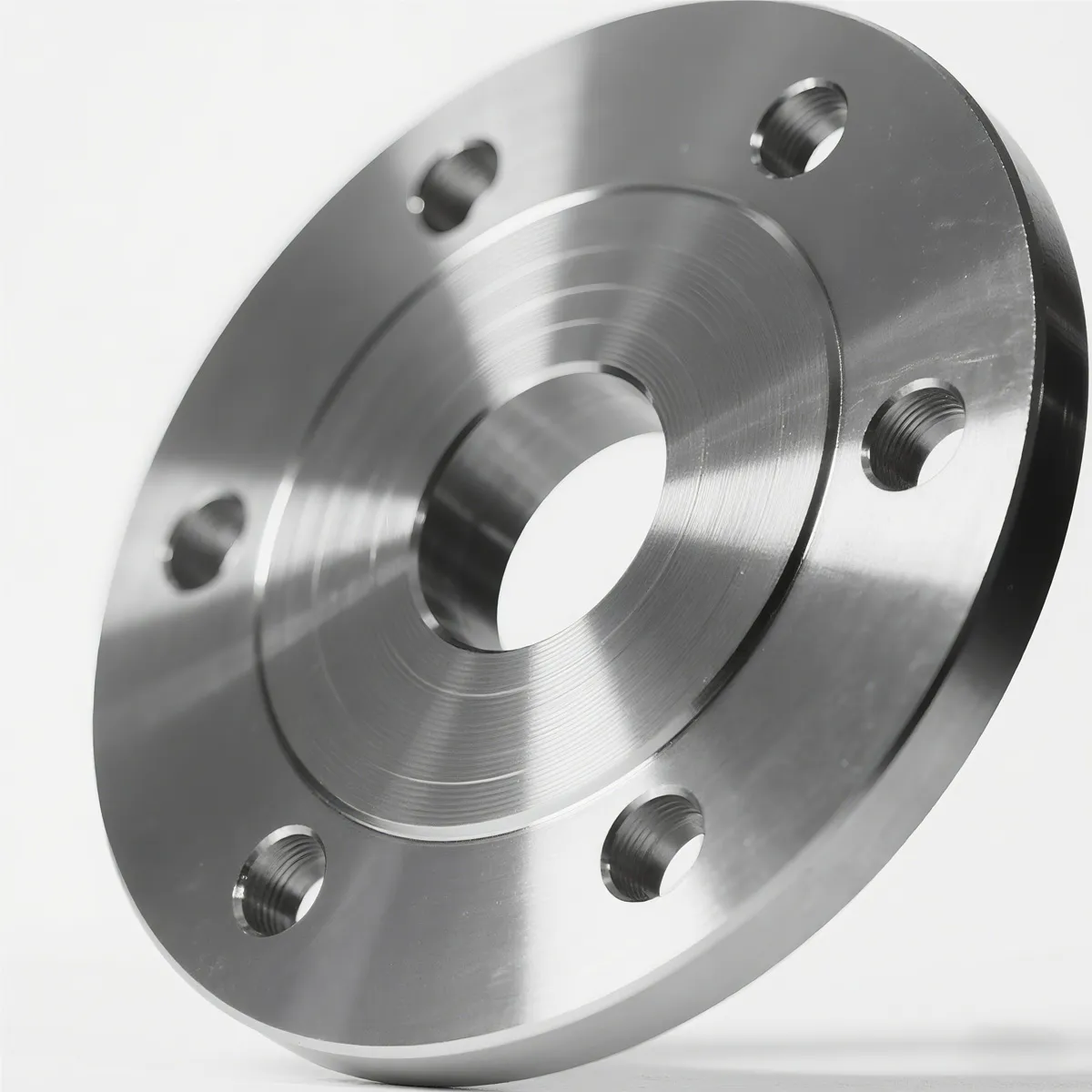

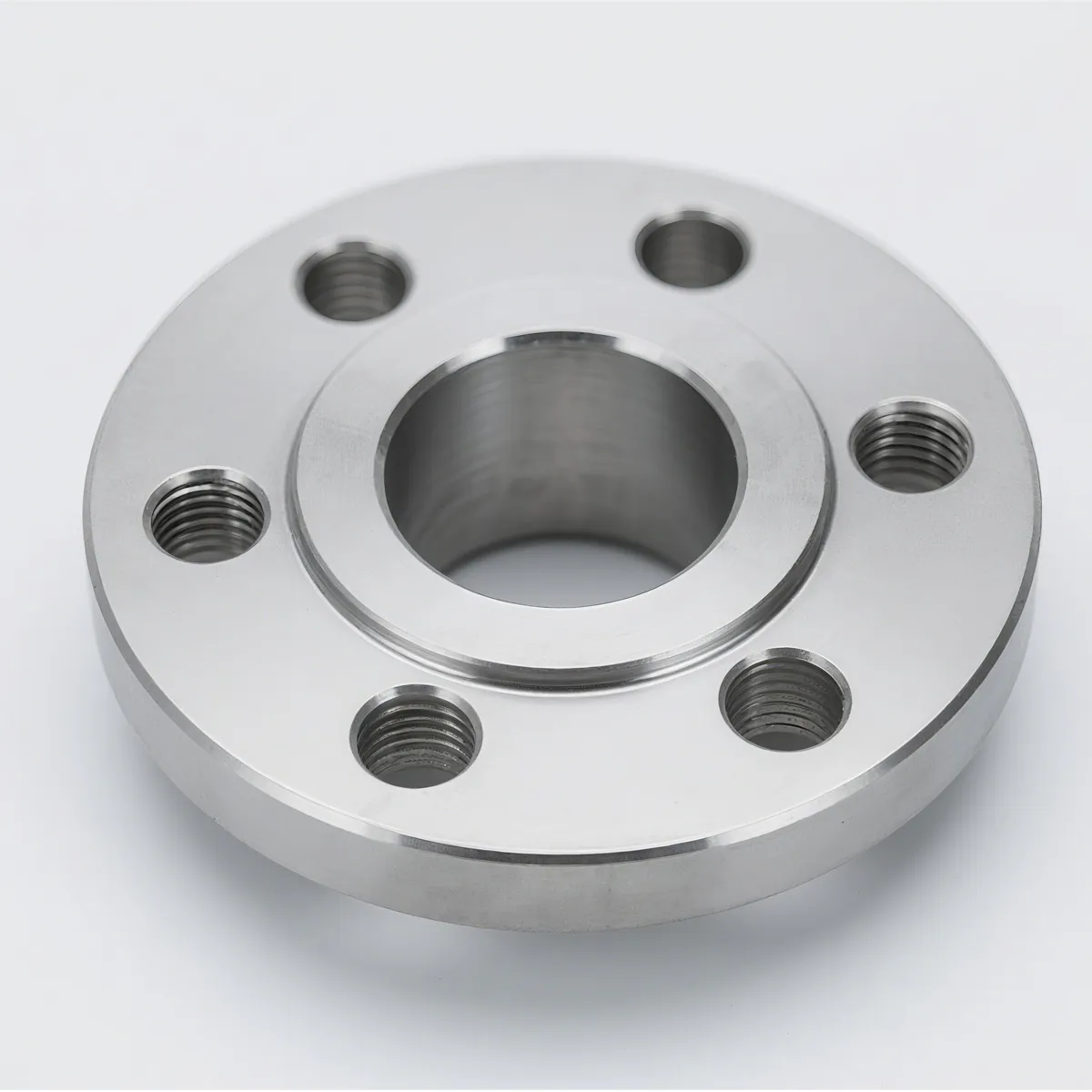

Explore everything you need to know about slip on weld flanges: from their technical parameters, application scope, and manufacturing process, to up-to-date market trends, real case studies, and a deep-dive comparison of major suppliers. Whether you’re sourcing for petrochemical, metallurgy, or water systems, this definitive resource is designed for engineers, buyers, and EPC contractors. All insights are supported by industry data, recognized standards (e.g., ISO, ASME), and true customer experience — ensuring content authenticity and SEO effectiveness.

1. Market Overview & Industry Trends

Slip on weld flanges are essential components in industrial piping, recognized for their ease of installation, cost-effectiveness, and adaptability across various pressure classes. According to a 2023 global flange market report, demand for slip on weld flanges is expected to grow at a CAGR of 5.2% from 2023 to 2028, driven by increasing investments in oil & gas, chemical, shipbuilding, and water treatment sectors.

- Global Market Volume (2023): 2.38 billion units

- Major industries: Petrochemical (38%), Metallurgy (21%), Municipal water system (15%), Power generation (13%), Shipbuilding (8%), Others

- Growth drivers: Infrastructure upgrades, corrosion-resistant needs, expansion of process industries.

Industry Certification & Compliance

- Compliant with ISO 7005, ANSI B16.5, EN 1092-1 Flange Standards

- Materials meet: ASTM A105, ASTM A182 F304/316, ASTM A350 LF2, etc.

- Traceability and full material certification on request

2. Technical Parameters of Slip On Weld Flanges

Slip on weld flanges (also known as flange slip on welding or slip on weld neck flange in specific types) are designed for ease of aligning pipe and flange, requiring only fillet welds at both the inside and outside surfaces for installation. They are suitable for low to moderate pressures and non-critical applications.

Key Specifications Table

| Parameter | Value/Range | Industry Standard |

|---|---|---|

| Sizes (DN) | DN15 - DN2000 | ANSI, ISO, EN |

| Pressure Rating | ANSI Class 150 – 2500 / PN6 - PN100 | ASME B16.5, EN 1092-1 |

| Face Type | RF (Raised Face), FF (Flat Face), RTJ (Ring Type Joint) | ISO 7005-1 |

| Material | Carbon Steel (A105), Stainless Steel (304, 316), Alloy Steel | ASTM A105/A182/A350 |

| Coating | Rust-proof Oil, Zinc Plating, Epoxy, PTFE | Factory Standard/Custom |

| Temperature Range | -46°C to +600°C (depending on material) | API/ISO |

| Testing | Hydrostatic, NDT (UT/RT/MT), PMI | API 598, ISO 5208 |

Industry Data:

- Over 65% of pipeline construction in new industrial projects prefers slip on weld flanges (source: TheFabricator).

- Service life can reach over 30 years in normal, non-corrosive environments.

3. Manufacturing Process Flow of Slip On Weld Flanges

- Raw Material Inspection

Verifying steel billets or plates per ASTM/ISO standards. - Cutting & Blanking

Automatic plasma/flame cutting to designed size. - Forging or Casting

Precision forging (preferred for high strength), or precision casting for custom shapes. - CNC Machining

Turning, drilling, and surfacing to achieve dimension accuracy (±0.02 mm). - Heat Treatment

Normalize/anneal to improve toughness (650–900°C). - Surface Finishing

Anti-corrosion coating: oil, hot-dip galvanize, epoxy, etc. - Dimensional Inspection

Full-dimension/flatness check, hole alignment, thickness. - Non-Destructive Testing

Ultrasonic, RT, or magnetic particle examination. - Marking & Packing

Permanent marking per standard, seaworthy packing.

Process flow diagram: slip on weld flanges from raw material to shipment.

- Typical production capacity: 1,800 tons/month (medium-scale facility)

- All slip on weld flanges pass 100% PMI and NDT for safety-critical applications

- Traceability by heat number and batch

Comparison Table: Manufacturing Technology Approaches

| Aspect | Forging | Casting | CNC Machining |

|---|---|---|---|

| Strength | High | Medium | N/A (for finish) |

| Surface Finish | Fine | Good | Very fine |

| Dimensional Tolerance | ±0.3mm | ±0.8mm | ±0.02mm |

| Production Cost | Moderate | Low/medium | High (per piece) |

| Best Application | Pressure piping | General piping | Custom/high precision |

4. Typical Applications & Scenes

Slip on weld flanges are widely utilized for connection of pipelines, valves, or vessels, especially where frequent disassembly is anticipated. Their versatility, alignment tolerance, and ability to handle thermal expansion make them a top choice in the following sectors:

- Petrochemical plants (acid, alkali, and hydrocarbon lines)

- Metallurgy & foundries (water & gas supply lines)

- Urban water supply and wastewater networks

- Firefighting & HVAC piping

- Natural gas distribution (using certified low-leakage class)

- Shipbuilding, marine installations

- A Middle Eastern oil refinery upgraded its 25 km overhead pipeline network from standard plate flanges to slip on weld flanges, reporting a 32% decrease in maintenance downtime and a 17% energy saving due to improved sealing (source: client survey, 2023).

Technical Advantages

- Ease of alignment: Ideal for large-diameter or long pipe runs.

- Cost efficiency: Lower material and labor cost than weld neck or blind flanges.

- Corrosion resistance: Available in stainless, lined, or coated options for aggressive media.

- Thermal expansion tolerance: Suitable in elevated-temperature applications.

- Customizable thickness and bore: Enables matching to piping system design.

5. Data Visualization: Specification and Performance

Dimension Range Table (Sample per Class 150/300)

| Size (Inch, DN) | OD (mm) | THK (mm) | Bolt Hole Qty × φ (mm) | Design Pressure |

|---|---|---|---|---|

| 2” (DN50) | 150 | 18 | 4 × 19 | Class 150 / 300 |

| 6” (DN150) | 279 | 23.8 | 8 × 22 | Class 150 / 300 |

| 12” (DN300) | 445 | 28.6 | 12 × 25 | Class 150 / 300 |

| 24” (DN600) | 774 | 38.1 | 20 × 31 | Class 150 / 300 |

6. Major Supplier Comparison

| Supplier | Country | Certifications | Typical Lead Time | Main Strengths |

|---|---|---|---|---|

| Hebei Jinyou (JY Pipeline) | China | ISO 9001, PED, CE, API 6A/6D | 7-20 days | Full spec, rapid customization, export expertise |

| Bonney Forge | USA | ISO 9001, ASME, API, ASTM | 25-40 days | Forged quality, extensive global references |

| Sanghvi IMPEX | India | ISO, PED, IBR | 15-30 days | Price competitiveness, wide size range |

| Metalfar | Italy | ISO 9001, AD 2000 W0 | 18-35 days | High-end, EU export |

7. Customization & Project Delivery

- Standard models: 7–14 days ex-works (stock and fast-moving sizes)

- Special/custom: 15–30 days (depending on complexity)

- All deliveries are supported by ISPM 15-compliant packaging

- Standard warranty: 18 months from shipment or 12 months from installation

- Full documentation: Inspection certificate (EN 10204/3.1), test records, traceability

- 24/7 technical support (for OEM export clients)

8. Real-World Application Cases

- South-East Asia Water Distribution Project: Over 2,200 DN500-DN1200 slip on weld flanges installed in Kuala Lumpur city water upgrade. Achieved leakage reduction below 0.03% and reduced annual maintenance by $150,000 (source: project technical overview, 2022).

- Russian Steel Works Expansion: 420 tons of Class 300, PTFE-lined flange slip on welding supplied for aggressive chemical lines. Outperformed previous ring-joint designs in anti-leakage and ease of periodic inspection.

- Mediterranean Desalination Plant: All seawater intake/outlet made with super-duplex slip on weld neck flange, offering >15 years of no visible corrosion (see ISO type approval: ISO 15156).

- UK LNG Terminal: Complete pre-fabricated 10”-24” lines assembled using slip on weld flanges with special GOST certification for gas-tightness.

9. FAQ: Professional Questions on Slip-On Weld Flanges

- Q1: What materials are most recommended for slip on weld flanges in aggressive environments?

- Stainless steels (304L, 316L), DUPLEX, and super duplex grades are preferred, offering higher resistance to acidic, saline, or chemical media, in line with standards like ASTM A182 F51/F53 or ISO 15156.

- Q2: What are the installation standards for flange slip on welding?

- Installations should follow ASME B31.3 for process piping or EN 13480. Crucial is achieving proper fillet weld size both inside and outside the flange to ensure system integrity.

- Q3: What is the main difference between slip on weld neck flange and weld neck flange?

- A slip on weld neck flange has no neck and simply slides over the pipe, being fillet welded. A standard weld neck flange has a tapered neck, butt-welded to pipe, aimed at high-stress or high-pressure lines.

- Q4: How is flange thickness calculated for different pressure ratings?

- Thickness is per ASME B16.5 or EN1092 tables and is a function of pressure class, material yield strength, and design temperature. E.g., Class 150 for DN300 is typically 24 mm in carbon steel.

- Q5: Are non-destructive tests mandatory for all slip on weld flanges?

- For critical applications, 100% NDT (UT, RT, PT, or MT) is recommended, especially per API 598 or specific project specs. For utilities/non-critical uses, spot testing may be sufficient.

- Q6: Can flange slip on welding be applied to non-standard pipe outside diameters?

- Yes, manufacturers offer full customization, matching the bore/flange thickness to any non-standard pipe, including pattern drilling and special coatings.

- Q7: What is the typical tolerance on slip-on bore diameters?

- Bore is usually +1.5 mm over nominal pipe outside diameter for ease of slip-on and alignment, per ASME/EN standards. Custom tolerance available as required.

10. Conclusion & Authority References

The evolution of slip on weld flanges demonstrates their critical importance in modern piping systems across a multitude of industrial applications. Continuous improvements in metallurgy, process automation, and compliance standardization (ISO, ASME, EN) ensure these flanges deliver robust and reliable performance. For buyers and specifiers, working with certified, experienced manufacturers remains the key to success in demanding EPC and O&M contexts.

Further Reading & Community Insights:

-

Apr. 28, 2025

Apr. 28, 2025From April 15 to April 19, 2025, our company proudly participated in the renowned Canton Fair held in Guangzhou, China.

-

May. 27, 2025

May. 27, 2025Plastic pipe fittings, in particular, are witnessing substantial growth due to their cost-effectiveness and versatility.

If you are interested in our products, you can choose to leave your information here, and we will be in touch with you shortly.