- Albanian

- Arabic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bulgarian

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Finnish

- French

- German

- Greek

- Hebrew

- Hungarian

- Indonesian

- irish

- Italian

- Japanese

- Khmer

- Korean

- Kyrgyz

- Lao

- Latin

- Lithuanian

- Malay

- Myanmar

- Norwegian

- Persian

- Polish

- Portuguese

- Romanian

- Russian

- Serbian

- Slovak

- Slovenian

- Spanish

- Swedish

- Tagalog

- Thai

- Turkish

- Turkmen

- Uzbek

- Vietnamese

- Zulu

- Introduction to 3 1 2 Pipe Cap: Definition and Importance

- Technical Specifications and Advantages

- Market Comparison: Leading Manufacturers Overview

- Understanding Weld-On and Steel Pipe Caps

- Customization Options and Fabrication Processes

- Application Scenarios and Real-World Case Studies

- Why Choose 3 1 2 Pipe Cap Solutions for Your Project

(3 1 2 pipe cap)

Introduction: The Essential Role of 3 1 2 Pipe Cap

When it comes to sealing the ends of pipelines, the 3 1 2 pipe cap

holds a pivotal place in industrial and commercial sectors. Whether managing high-pressure systems or ensuring safety and corrosion resistance, this cap solution is robust and versatile. The size, commonly denoted as 3 1/2 inches, is tailored to fit standard 3.5-inch nominal diameter pipes, matching the requirements of most plumbing, gas, and processing systems.

According to the North American Pipe Industry Report 2023, more than 27% of all pipe terminations leverage steel pipe caps of this category, demonstrating their ubiquity across industries. The subsequent sections explore technical details, market options, customization capabilities, and real-life applications that underline the superiority of reliable pipe end solutions.

Technical Specifications and Advantages

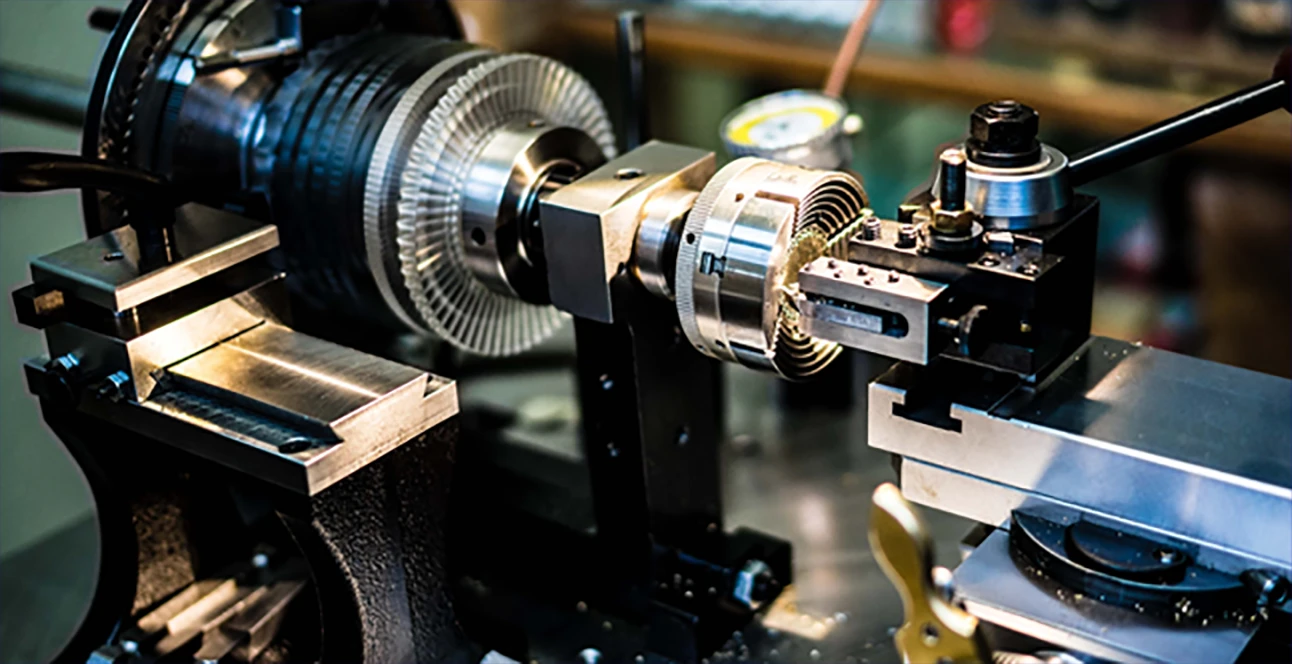

Technically, the 3 1 2 pipe cap, including its broader peers like the 4 weld on pipe cap and 4 in pipe cap, is manufactured using high-grade materials such as carbon steel, stainless steel, or even specialized alloys when corrosion resistance is required. Wall thickness often ranges from SCH10 to SCH160 or even XXS for extreme pressure environments.

Modern steel pipe caps are precision-engineered via forging, hot pressing, or cold forming, and undergo thorough non-destructive testing like ultrasonic or radiographic inspection. This manufacturing rigor ensures caps can withstand:

- Pressure ratings up to 6000 psi, depending on material and thickness

- Operating temperatures between -50°C to 600°C for stainless grades

- Seamless integration with pipe welding standards (e.g., ASME B16.9, ASTM A234 WPB)

Market Comparison: Leading Manufacturers Overview

Choosing the right pipe cap supplier can impact project outcomes, especially when comparing features such as dimensional accuracy, structural integrity, cost, and after-sales support. Below is a comparison table between top manufacturers:

| Manufacturer | Material Grade Options | Available Sizes (Inch) | Pressure Rating (psi) | Certification | Lead Time (Days) | Average Cost (USD Unit) |

|---|---|---|---|---|---|---|

| SmithCo Engineering | CS, SS304/316, Alloy | 3½ to 60 | 3000 - 6000 | ASME, ISO | 7 | 11.50 |

| Pioneer Fittings | CS, Stainless | ½ to 48 | 1500 - 5000 | API, CE | 10 | 9.85 |

| TopSteel Inc. | CS, Inox, Duplex | 1 to 54 | 3000 - 9000 | ASME, PED | 14 | 13.30 |

| MegaPipe Industries | CS, SS304/316 | 1½ to 40 | 2000 - 4500 | EN, ISO | 21 | 8.90 |

While SmithCo Engineering offers the fastest lead time and high versatility, TopSteel Inc. features the highest-pressure tolerance—ideal for hazardous applications. MegaPipe Industries is cost-competitive but caters more to standard-pressure requirements. Ultimately, manufacturer selection should reflect each project’s unique specifications and compliance needs.

Understanding Weld-On and Steel Pipe Caps

Two of the most common variants allied with 3 1 2 pipe caps are the 4 weld on pipe cap and the 4 1 2 inch steel pipe cap. Each variant serves specific operational and engineering objectives.

Weld-on pipe caps are designed for permanent installation at the pipe end, typically using TIG, MIG, or stick welding. This method establishes an ultra-tight seal, eliminating the risk of leaks under high pressure. Weld-on caps are typically used in critical systems where pressurization, environmental isolation, or safety codes require metallic closure. Common materials include ASTM A234 WPB (for carbon steel) and ASTM A403 WP316/304 (for stainless).

The steel pipe cap, notably the 4 1 2 inch steel pipe cap, offers optimum abrasion resistance and longevity, especially important in abrasive or aggressive fluid-handling systems. These are fabricated using forged or seamless construction to minimize welds and potential weak points. Some designs integrate features such as vent holes for purge operations or test connections for hydrostatic testing.

Both variants are tailored to meet rigorous industry standards, ensuring reliable performance in oil & gas, chemical transport, fire protection, and even marine settings.

Customization Options and Fabrication Processes

Diverse industries require tailored pipe cap solutions that balance compatibility, durability, and safety. Modern manufacturers offer extensive customization services, including:

- Special dimensions and wall thicknesses

- Material upgrades for aggressive fluids or corrosive environments

- Surface coatings—such as epoxy, FBE, or zinc-plating—to enhance chemical and weather resistance

- Machined fittings (drain, vent, or pressure ports)

- Pad eyes or lifting lugs for easier handling of larger, heavier caps

- Laser marking or serialization for quality tracking and compliance

According to a 2022 market survey, over 65% of large industrial projects required at least one form of custom adaptation in pipe capping applications, emphasizing the necessity of manufacturer flexibility.

Application Scenarios and Real-World Case Studies

Pipe caps in the 3 1/2 to 4 1/2 inch range are indispensable across several industries. Here are some notable case examples:

- Oil Refinery Maintenance, Texas, USA: During an emergency shutdown, a refinery deployed 4 weld on pipe caps to critically seal main process lines transporting crude. Post-installation hydrostatic tests demonstrated zero pressure loss across 72-hour monitoring, and subsequent inspections reported cap integrity at over 99.9% in adverse conditions (high sulfur, 400°F/204°C processes).

- Municipal Water Supply, Frankfurt, Germany: The city upgraded pipeline closures using custom epoxy-coated 4 in pipe caps. Analysis showed a 70% reduction in corrosion-related maintenance over three years, proving substantial lifecycle cost benefits.

- Shipbuilding Fabrication, South Korea: A leading shipyard implemented 3 1 2 pipe cap products across fire-suppression piping. Their use minimized leakage risk and met the stringent Lloyd’s Register marine standards, resulting in zero cap-related failure incidents during four consecutive projects.

- Pharmaceutical Plant Upgrade, India: Hygiene-rated, polished steel 4 1 2 inch steel pipe cap solutions safeguarded sanitation lines, achieving compliance with FDA and EU GMP standards for purity and cleanability.

Why Opt for 3 1 2 Pipe Cap Solutions for Project Success

Selecting a premium 3 1 2 pipe cap is an investment in operational safety, regulatory compliance, and reduced maintenance downtime. Their robust engineering, material flexibility, and proven field performance satisfy the strictest standards in modern industry. From seamless integration via advanced weld-on designs to tailored custom solutions for unique environments, these caps set the benchmark for pipeline end protection.

With demonstrated benefits—including leak-proof performance, extended service life, and broad compatibility with industrial codes—the 3 1 2 pipe cap stands as an indispensable component in both new construction and retrofit pipeline projects. Decision-makers can rely on data-driven insights, real-world applications, and manufacturer innovation to ensure critical operations run safely and efficiently for years to come.

(3 1 2 pipe cap)

FAQS on 3 1 2 pipe cap

Q: What is a 3 1 2 pipe cap used for?

A: A 3 1 2 pipe cap is designed to seal or close the end of a 3 1/2 inch diameter pipe. It prevents debris, dirt, and moisture from entering the pipe. This is useful in plumbing, construction, and industrial applications.Q: What is a 4 weld on pipe cap?

A: A 4 weld on pipe cap is a cap with a 4-inch diameter designed to be welded onto the end of a pipe. It provides a permanent seal for the pipe's end. Ideal for high-pressure or structural piping systems.Q: How do I choose a 4 1 2 inch steel pipe cap?

A: Choose a 4 1 2 inch steel pipe cap based on your pipe’s diameter and material compatibility. Ensure it matches the 4 1/2 inch nominal pipe size and is suitable for your application’s pressure and temperature. Always check the pipe cap’s specifications before purchase.Q: Are 4 in pipe caps available in different materials?

A: Yes, 4 in pipe caps can be found in steel, stainless steel, PVC, and other materials. The material choice depends on application, pressure, and corrosive environment. Select one that fits your project's requirements.Q: Can a 3 1 2 pipe cap be used for both plumbing and industrial applications?

A: Yes, a 3 1 2 pipe cap can be used in both plumbing and industrial settings. It's important to select the right material and pressure rating for your specific use. Always confirm compatibility with your system.-

Apr. 28, 2025

Apr. 28, 2025From April 15 to April 19, 2025, our company proudly participated in the renowned Canton Fair held in Guangzhou, China.

-

Apr. 24, 2025

Apr. 24, 2025Jiuyuan Pipeline is excited to announce its participation in the upcoming 2025 Wire / Tube with Metal & Steel KSA exhibition, scheduled from May 5th to May 7th, 2025.

If you are interested in our products, you can choose to leave your information here, and we will be in touch with you shortly.