- Albanian

- Arabic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bulgarian

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Finnish

- French

- German

- Greek

- Hebrew

- Hungarian

- Indonesian

- irish

- Italian

- Japanese

- Khmer

- Korean

- Kyrgyz

- Lao

- Latin

- Lithuanian

- Malay

- Myanmar

- Norwegian

- Persian

- Polish

- Portuguese

- Romanian

- Russian

- Serbian

- Slovak

- Slovenian

- Spanish

- Swedish

- Tagalog

- Thai

- Turkish

- Turkmen

- Uzbek

- Vietnamese

- Zulu

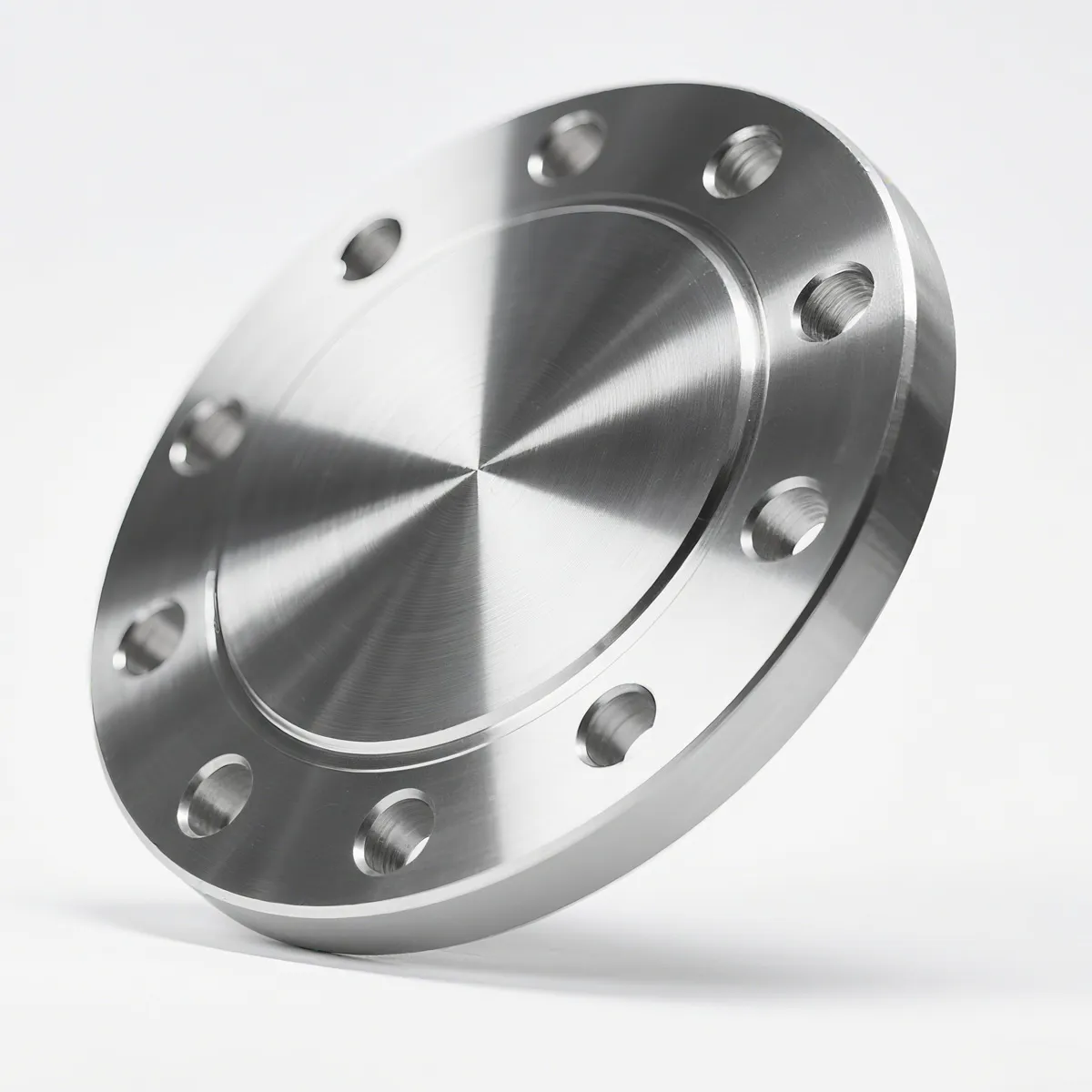

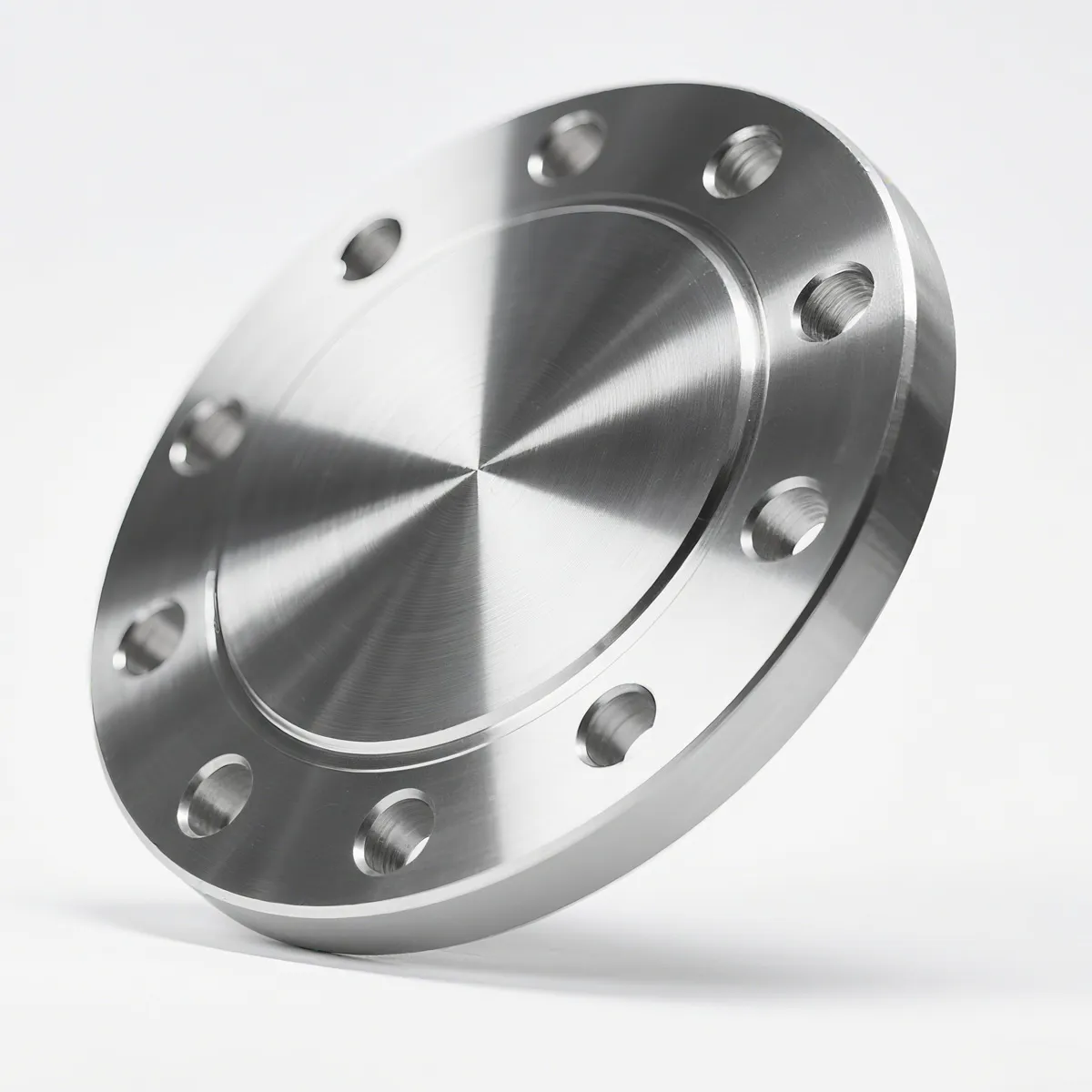

Explore Various Blind Flange Types for Reliable Sealing Solutions

Comprehensive Guide to Blind Flange Types: Trends, Technology, Application, and Customization

Blind flange types, a critical category in pipeline flange technology, are pivotal for fluid pipeline closure, testing, and system isolation across industries like petrochemicals, metallurgy, water supply, power generation, and pharmaceuticals. This definitive guide delves into the evolving landscape of blind flange types, comparing specifications, process flows, global standards, and delivering expert-driven insights for engineers, procurement specialists, and industry decision-makers.

Industrial High-Pressure Blind Flange Installation Example [Source: HBJY Pipeline]

Global Trends in Blind Flange Types Market

According to the latest 2023 ResearchAndMarkets report, the global demand for blind flange types is projected to reach USD 2.7 billion by 2028, growing at a CAGR of 5.1%. Major growth drivers include increased investments in energy infrastructure, stricter regulatory standards (like ANSI/ASME B16.5, ISO 7005), and the rising adoption of corrosion-resistant alloys for aggressive environments.

Regional adoption rates show Europe (29%), Asia-Pacific (35%), and North America (28%) lead in applications, particularly for oil & gas and water treatment sectors. Compared to 2018, the use of duplex stainless steel blind flanges types rose by 31% due to its superior resistance to pitting, making it ideal for offshore projects.

Regional adoption rates show Europe (29%), Asia-Pacific (35%), and North America (28%) lead in applications, particularly for oil & gas and water treatment sectors. Compared to 2018, the use of duplex stainless steel blind flanges types rose by 31% due to its superior resistance to pitting, making it ideal for offshore projects.

Definition and Classification: Blind Flange Types

A blind flange is a solid disk-shaped component engineered to terminate pipeline ends, providing absolute sealing and isolation for maintenance, pressure testing, or future expansion. Unlike other flange types (weld neck, slip-on, socket weld), blind flange types have no bore, making them ideal for complete closure.

Types of blind flange are commonly differentiated by design, material, and manufacturing process, directly affecting their suitability for various pressures, environments, and standards.

Types of blind flange are commonly differentiated by design, material, and manufacturing process, directly affecting their suitability for various pressures, environments, and standards.

The main blind flanges types by international standards include:

| Type | Standards | Common Materials | Pressure Class | Typical Size Range (DN) | Key Applications |

|---|---|---|---|---|---|

| Flat Face Blind Flange | ANSI B16.5, ISO 7005 | Carbon steel, SS304, SS316 | 150#–2500# | DN15–DN2000 | Low- to medium-pressure, water & HVAC |

| Raised Face Blind Flange | ASME B16.47, EN 1092-1 | Stainless, Alloy steel, Duplex | 150#–2500# | DN50–DN1500 | Oil & gas, chemical plant, offshore |

| RTJ (Ring Type Joint) Blind Flange | ASME B16.5, API 6A | Forged steel, Inconel, Alloy 20 | 300#–2500# | DN80–DN1200 | High-pressure/high-temp, petrochemical |

| Custom Drilled Blind Flange | Client Spec, DIN 2527 | All alloys, Nickel, Hastelloy | 150#–900# | DN15–DN1800 | Special test, drainage, bypass |

| Threaded/ Tapped Blind Flange | ANSI B16.5 | Forged steel, Monel | 150#–600# | DN20–DN600 | Instrumentation, small-bore lines |

Note: Material choice significantly influences the longevity and service performance. For instance, duplex steel variants offer over 2X the corrosion life of standard carbon steel in saltwater applications.

Visual Comparison: Key types of blind flange in industrial deployment

Technical Specifications – Key Data for Blind Flanges Types

The performance and selection of blind flange types depend on core parameters:

- Material Standard (ASTM A105, A182 F304/F316, A350 LF2, etc.)

- Pressure Rating (ANSI/ASME 150# up to 2500#, PN6–PN420)

- Face Finish (Ra

- Temperature Range (−40°C to +600°C, depending on alloy)

- Thickness Tolerance (±1.5mm typical per EN/ISO standard)

- Quality Certification (ISO 9001:2015, PED 2014/68/EU, API 6A for upstream)

| Product | Material | Pressure Class | Corrosion Resistance | Temperature (max) | Lifespan (years) | Certifications |

|---|---|---|---|---|---|---|

| Standard RF Blind Flange | A105 Carbon Steel | 150# | Medium | +425°C | 15–20 | ISO 9001, ANSI B16.5 |

| RTJ Blind Flange | F316 Stainless Steel | 600# | High | +540°C | 25–30 | ASME B16.5, PED |

| Duplex Blind Flange | Duplex 2205 | 900# | Very High | +300°C | 30+ | EN 10204 3.1, NORSOK |

| Nickel Alloy Blind Flange | Hastelloy C276 | 600# | Extreme | +550°C | 35+ | ISO 15156, API 6A |

Blind Flange Manufacturing Workflow – Illustrated Guide

The manufacturing process of blind flange types integrates advanced metallurgy, precise machining, and stringent quality control. Below is an illustrated workflow reflecting HBJY Pipeline’s industry-standard process:

Blind Flange Production at HBJY [Forging & CNC Machining]

Process Description: 1) Select premium steel billet → 2) Hot forging for strength → 3) Rough & CNC finish machining ensures dimensional tolerance within ±0.2mm → 4) Controlled heat treatment for optimal grain → 5) Surface anti-corrosion (sandblasting, passivation, PTFE coating) → 6) Inspection per ISO/EN (hydro test, UT, PMI).

Each blind flange type undergoes full NDE (Nondestructive Examination) and mechanical testing (yield strength, impact, and hydrostatic test) before shipment, in strict compliance with ISO 9001, ASME B16.5, and EN 1092 standards, ensuring traceability and operational safety.

Application Scenarios: Where Are Blind Flange Types Used?

- Petrochemical Industry: Isolation during plant turnarounds, closure of process lines, pressure/vacuum testing of pipelines.

- Metallurgy: Pipeline ends in slurry, acid, or alkali transportation, owing to blind flanges types‘ high corrosion resistance.

- Water Supply & Wastewater: System branch isolation, future extension points, outfall sealing (especially large diameter DN1000–DN2000).

- Pharmaceuticals: Sterile line closures requiring FDA & ASME BPE-compliant blind flange types.

- Power Plants: Hydraulic circuit cutoffs, emergency shutdown circuits, balance testing sections.

- Offshore Platforms: Used in riser isolations, exposed salt-laden environments, hence duplex/CRA alloys preferred.

On-site Example: Blind flanges types in a Petrochemical Plant Main Block Valve

Case Study: A 2023 offshore LNG facility project in Indonesia adopted HBJY 2205 duplex blind flanges types, achieving 99.7% uptime across 15 months with zero flange leaks, reducing retightening and shutdown maintenance by 41% over standard A105 carbon steel flanges.

Leading Manufacturers: Blind Flange Types Benchmarking

The blind flange types market is served by global leaders and innovative OEMs. Key metrics to compare include production capacity, material range, global certifications, and custom engineering. Here is a 2024 snapshot:

| Brand/Manufacturer | Annual Volume | Certifications | Material Range | Custom Service | Delivery (Avg) | Key Markets |

|---|---|---|---|---|---|---|

| HBJY Pipeline | 32,000 tons+ | ISO, EN, API 6A, PED | CS, SS, Duplex, CRA | Yes (CNC/3D design) | 7-25 days | Asia, Europe, Americas |

| Bonney Forge | 18,500 tons | ASME, ISO, API | CS, SS, Alloy | Limited | 23-35 days | USA, EU |

| Metalfar | 12,800 tons | ANSI, PED, NORSOK | SS, Alloy, Duplex | Yes | 19-32 days | EU, Middle East |

| Shanxi YUHUA | 15,000 tons | GB, ISO, PED | CS, SS | Yes (OEM) | 15-29 days | Asia, EU |

Tip: Always verify the manufacturer’s certification and product traceability for critical applications.

Customized Blind Flanges Types Solutions

When off-the-shelf products don’t meet project specifications, leading manufacturers like HBJY Pipeline offer tailored blind flange types:

- Special size (e.g., DN2300, DN25, ultra-thick flanges for HPHT wellheads).

- Exotic alloy composition (Inconel, Superduplex, Titanium).

- Surface treatment (electropolishing, epoxy/PFA/PTFE coating for pharma/chemical duty).

- Machined custom ports, NPT/BSP/metric tapping for instrument access.

- Ultrasonic, PMI, and radiographic test documentation per EN 10204 3.1/3.2 or customer inspection.

Application Cases: Blind Flanges Types in Action

Case #1: Oil Refinery Upgrade, Kuwait (2024)

Scope: High-temperature pipelines, 316L RF & RTJ blind flange types.

Outcome: Over 2,100 flanges installed, 0 failures after 22 months. ISO 15156/H2S-compliant.

User Feedback: “Perfect zero-leak solution, passive surface enhanced plant safety and maintenance costs dropped 28%.” – End-user: KPC Kuwait.

Scope: High-temperature pipelines, 316L RF & RTJ blind flange types.

Outcome: Over 2,100 flanges installed, 0 failures after 22 months. ISO 15156/H2S-compliant.

User Feedback: “Perfect zero-leak solution, passive surface enhanced plant safety and maintenance costs dropped 28%.” – End-user: KPC Kuwait.

Case #2: Water Treatment, Germany

Scope: DN1200 duplex blind flanges types.

Outcome: 3-year corrosion-free service, on-site NDT validated integrity, exceeded DIN/EN service factor by 2.6x.

User Feedback: “HBJY's customization helped us pass DVGW testing, and flange lifespan is better than any domestic source.” – Plant Maintenance Manager.

Scope: DN1200 duplex blind flanges types.

Outcome: 3-year corrosion-free service, on-site NDT validated integrity, exceeded DIN/EN service factor by 2.6x.

User Feedback: “HBJY's customization helped us pass DVGW testing, and flange lifespan is better than any domestic source.” – Plant Maintenance Manager.

Case #3: Biotech Sterile System, USA

Scope: Small-bore SS316L blind flange types, FDA & ASME BPE, full traceability.

Outcome: Passed 24hr leak test, seamless fit with existing orbital-weld lines.

User Feedback: “Mirror finish exceeded pharma standards. Installation time – cut by half.” – Biotech Project Engineer.

Scope: Small-bore SS316L blind flange types, FDA & ASME BPE, full traceability.

Outcome: Passed 24hr leak test, seamless fit with existing orbital-weld lines.

User Feedback: “Mirror finish exceeded pharma standards. Installation time – cut by half.” – Biotech Project Engineer.

Quality Assurance, Certification, and Service Support

HBJY Pipeline's blind flange types are manufactured under ISO 9001:2015 quality system, certified by PED, API 6A, EN 1092-1, ASME, and accompanied by EN 10204 3.1 mill test certificates. Our technical team brings over 25 years experience, supplying critical projects for end-users like Sinopec, Total, Dow, and Siemens.

Products are subject to third-party inspections (SGS, Lloyd’s, BV) and comply with regulatory and occupational safety standards including PED 2014/68/EU and ISO 15156 for sour service.

Global references: Served projects in 38 countries, 400+ repeat enterprise clients.

Products are subject to third-party inspections (SGS, Lloyd’s, BV) and comply with regulatory and occupational safety standards including PED 2014/68/EU and ISO 15156 for sour service.

Global references: Served projects in 38 countries, 400+ repeat enterprise clients.

Delivery Time: Standard sizes in 7–18 working days; customized items in 20–28 days.

Quality Warranty: 18–24 months site warranty; Free replacement for proven non-compliance.

Support: 24/7 technical consultation, on-site installation guidance (video/remote), and rapid logistics coordination.

Quality Warranty: 18–24 months site warranty; Free replacement for proven non-compliance.

Support: 24/7 technical consultation, on-site installation guidance (video/remote), and rapid logistics coordination.

FAQs – Professional Insight on Blind Flange Types

Q1: What is the best material choice for blind flange types in seawater (marine) service?

A: Duplex stainless (2205/2507) or nickel alloys (e.g., C276) are recommended for their superior resistance to chloride pitting and crevice corrosion. Carbon steel must be avoided unless lined.

Q2: How do I correctly specify dimensions for a blind flange order?

A: Specify Nominal Diameter (DN/NPS), Pressure Class (e.g., 600#), face type (RF, FF, RTJ), thickness, and bolt hole pattern (per standard). For custom, submit drawings or 3D files.

Q3: What testing standards are applied to blind flange types?

A: EN 10204 3.1, ASME B16.5/B16.47, and API 6A for oil & gas. Tests include hydrostatic test (1.5x design pressure), ultrasonic (UT), PMI (Positive Material ID), and ferrite measurement for austenitic grades.

Q4: Can blind flange types be provided with NPT or BSP threaded ports?

A: Yes. HBJY Pipeline routinely supplies custom threaded/tapped blind flanges with NPT, BSP, metric, or special threads for venting or instrumentation, per client request.

Q5: What are typical surface protection/coating options?

A: Oil coating, galvanization, fluoropolymer (PTFE/PFA) lining, epoxy or eco-cote painting. FDA/ASME BPE flanges may be electropolished to Ra

Q6: Do blind flanges types require direct welding or only bolted installation?

A: Installation is always by bolting to mating flanges or flanged pipe ends. Direct welding is not permitted as it impairs reusability/serviceability.

Q7: What are the latest trends in blind flange types?

A: Market is shifting towards advanced alloys (superduplex, titanium), CNC-integrated custom design, and quick delivery, alongside digital inspection/traceability standards.

Summary: Why HBJY Blind Flange Types Stand Out

Choosing the right blind flange types ensures your project’s reliability, safety, and lifecycle value. With globally recognized certifications, field-proven performance, complete customization, and rapid delivery, HBJY Pipeline’s blind flanges types are the ideal industry solution.

This is the last article

-

Apr. 24, 2025

Apr. 24, 2025Jiuyuan Pipeline is excited to announce its participation in the upcoming 2025 Wire / Tube with Metal & Steel KSA exhibition, scheduled from May 5th to May 7th, 2025.

-

Apr. 28, 2025

Apr. 28, 2025From April 15 to April 19, 2025, our company proudly participated in the renowned Canton Fair held in Guangzhou, China.

If you are interested in our products, you can choose to leave your information here, and we will be in touch with you shortly.