- Albanian

- Arabic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bulgarian

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Finnish

- French

- German

- Greek

- Hebrew

- Hungarian

- Indonesian

- irish

- Italian

- Japanese

- Khmer

- Korean

- Kyrgyz

- Lao

- Latin

- Lithuanian

- Malay

- Myanmar

- Norwegian

- Persian

- Polish

- Portuguese

- Romanian

- Russian

- Serbian

- Slovak

- Slovenian

- Spanish

- Swedish

- Tagalog

- Thai

- Turkish

- Turkmen

- Uzbek

- Vietnamese

- Zulu

Website: https://www.hbjypipeline.com

Phone: +86 18131702111

Email: sales@jypipeline.com

Mobile: +86 18131702111

Address: INDUSTRIAL DISTRICT OF NORTH CIRCLE, MENGCUN, CANGZHOU CITY, HEBEI PRVINCE, CHINA

Overview of Slip On Weld Flanges and Industry Trends

Slip on weld flanges are essential components in piping systems, providing secure, leak-proof connections for low-pressure and low-temperature industrial applications. As a cost-effective and easy-to-install solution, their usage continues to expand, especially in industries such as petroleum, chemical processing, power generation, shipbuilding, and water treatment. The global demand is expected to witness a sustained rise through 2030, driven by upgrading infrastructure and stricter reliability standards.

The increasing adoption of digital solutions and the move towards smart plants are shaping the future of slip on weld flanges, ensuring higher accuracy, traceability, and compliance with international standards. According to industry research (World Pipelines), the market for slip on weld neck flange and flange slip on welding has grown at over 4% CAGR for the past five years, underlining the product’s relevance and demand.

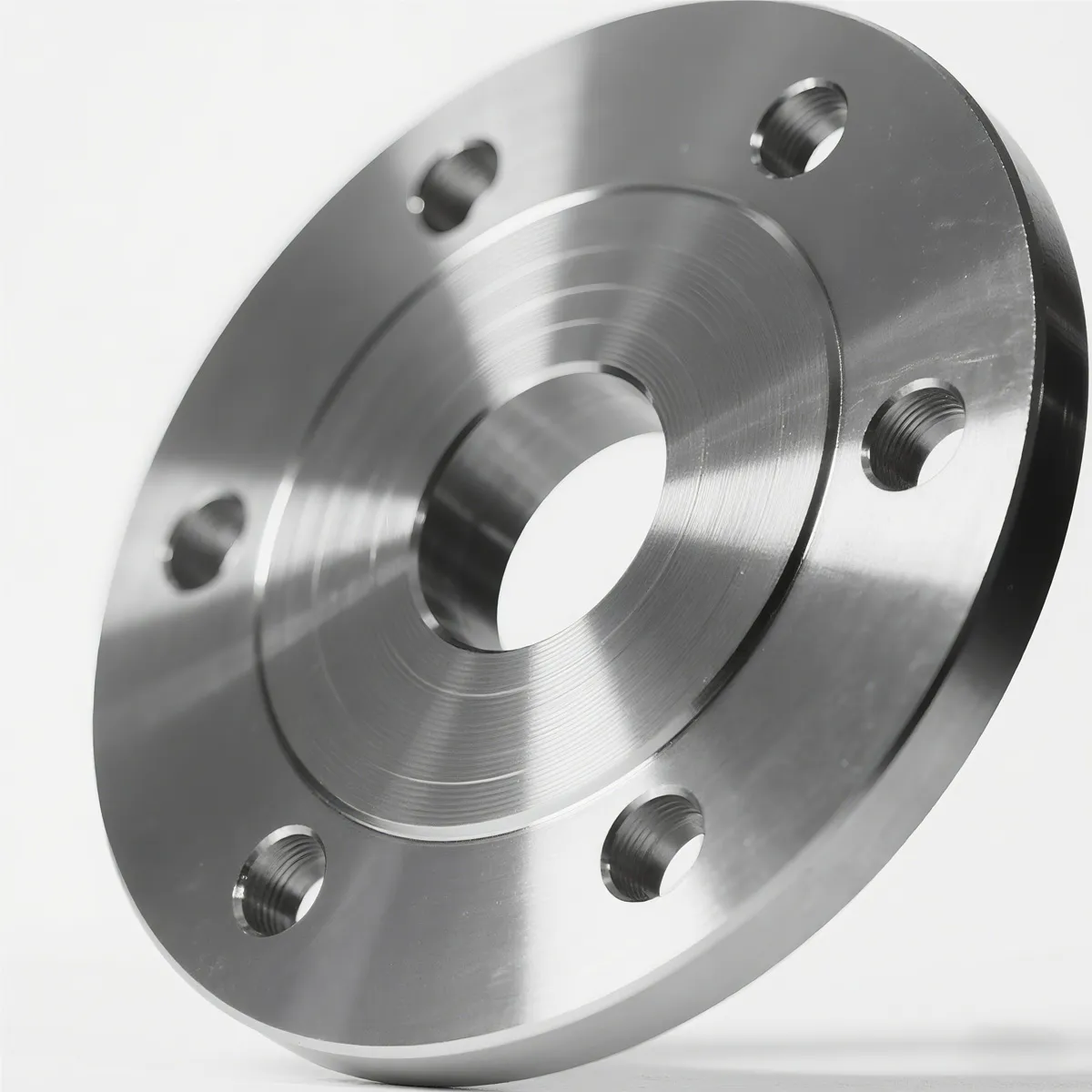

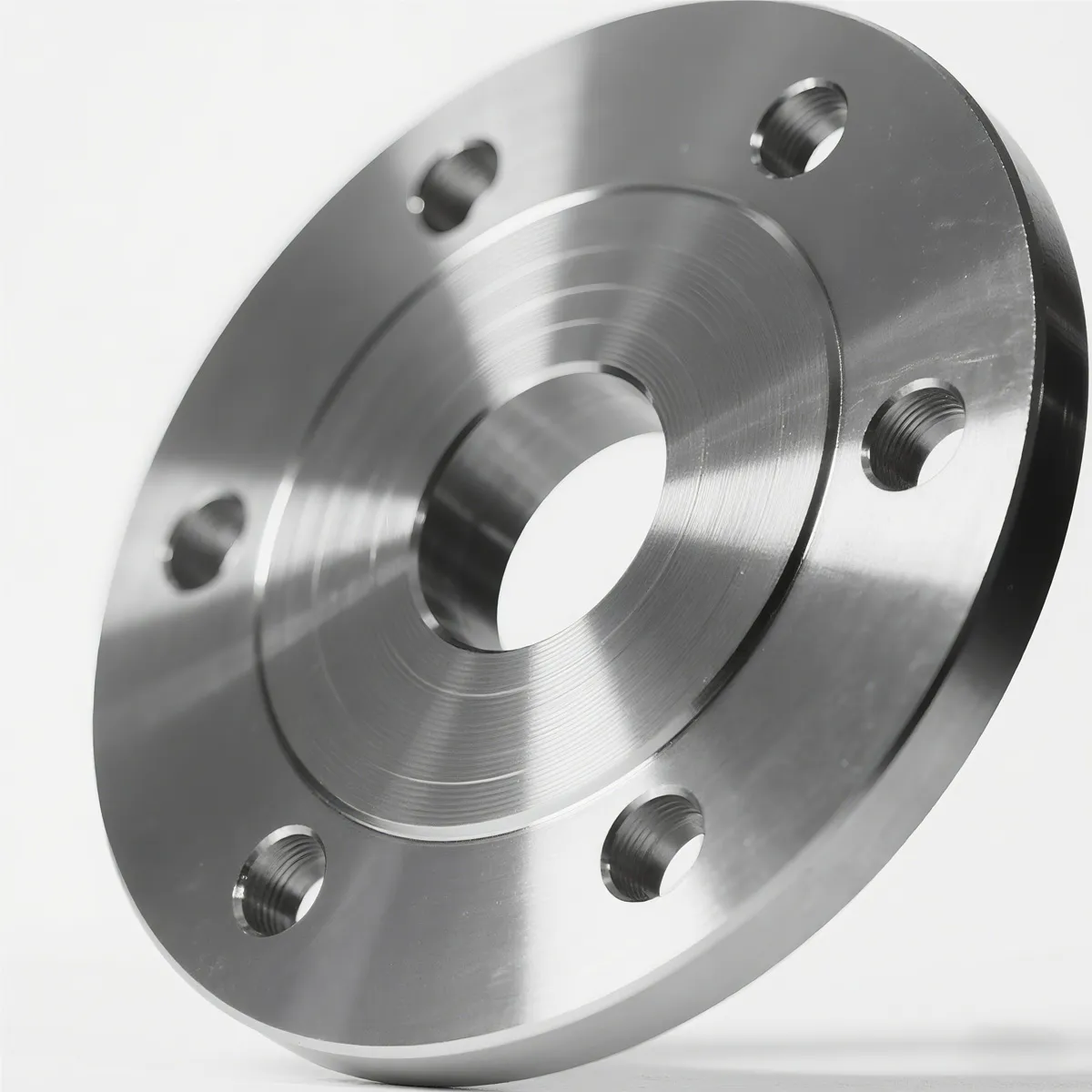

HEBEI JIUYUAN Slip-On Weld Flanges: Product Introduction

HEBEI JIUYUAN PIPELINE MANUFACTURING CO.,LTD. delivers first-class slip on weld flanges designed for superior performance, reliability, and versatility. Our Slip-On Weld Flanges are manufactured to stringent standards, ensuring exact tolerances and proven field performance.

Product Overview:

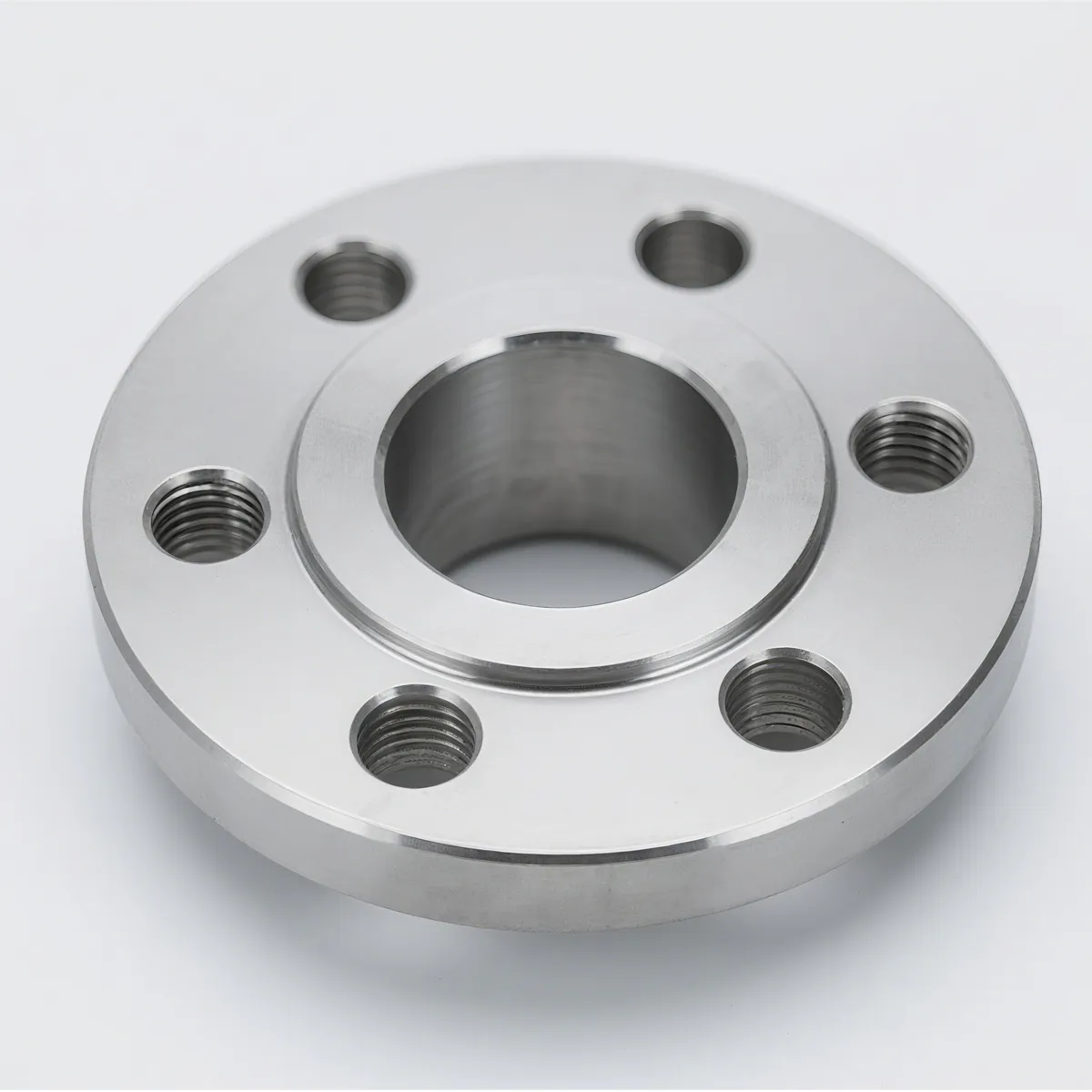

Slip-on weld flanges are designed for easy installation and reliable performance in a wide range of piping systems. These flanges slide over the pipe and are then welded both inside and outside to provide strength and prevent leakage. They are ideal for low-pressure and low-temperature applications, offering a cost-effective and efficient solution for connecting pipes, valves, and other equipment.

View Product Details

Technical Parameters Table for Slip On Weld Flanges

| Parameter | Specification Range | Standard | Common Material | Applicable Media |

|---|---|---|---|---|

| Nominal Size (DN) | 1/2" ~ 48" (15mm ~ 1200mm) | ANSI B16.5/EN 1092-1 | Carbon Steel, Stainless Steel, Alloy Steel | Water, Gas, Oil, Steam, Chemicals |

| Pressure Rating | Class 150, 300, 600, 900 | ASME/ANSI | Stainless Steel 304/316, ASTM A105, A350 LF2 | General Pipeline Use |

| Facing Type | RF (Raised Face), FF (Flat Face), RTJ (Ring-Type Joint) | EN1092, JIS B2220 | All Types | Pressure Sealing |

| Thickness | Standard, SCH 10 - SCH 160 | ASME B16.5 | Carbon Steel, Alloy | - |

| Coating/Finish | Rust-Proof Oil, Painted, Galvanized | ASTM, ISO | - | Corrosion Resistance |

| Welding Type | Slip-On, Weld Neck | ASME B16.5, B16.47 | Varies | - |

Slip-On Weld Flanges: Specification Distribution

Pressure Class Usage Trend

Material Ratio in Manufacturing

Comparative Technical Indicator Chart

Welded Strength Comparison (By Flange Type)

Application Share by Industry

Key Features & Technical Parameters of Slip On Weld Flanges

- Easy alignment and simple installation, reducing labor costs.

- Suitable for low to moderate pressure and temperature systems.

- Supports flange slip on welding process with both inner and outer welds for strength.

- Availability in broad material/spec sizes for versatile industry usage.

- Strictly adheres to global standards: ASME, ANSI, EN, JIS.

- Corrosion-resistant when produced with stainless steel or protected with special coating.

- Ideal for repeated assembly and disassembly applications.

Applications of Slip On Weld Flanges

Slip on weld flanges are deployed in numerous fields, including:

- Petrochemical & Refineries: Efficient in joining pipelines carrying crude oil, gas, steam, and process fluids.

- Power Generation: Used extensively in cooling water, boiler feed, steam distribution pipelines.

- Marine & Shipbuilding: They allow system modularization, resilience, and are preferred for storage, ballast, and waste pipelines.

- Water Treatment Plants: Suitable for low-pressure chlorination, water distribution, and waste management systems.

- Manufacturing & Industrial Facilities: Reliable for connecting machinery, pumps, and auxiliary equipment.

Professional Q&A: Slip On Weld Flanges Technical Terms

-

Q1: What are the typical materials used for slip on weld flanges?A1: Standard materials include Carbon Steel (ASTM A105), Stainless Steel (304, 316 grades), Alloy Steel (ASTM A182 F11, F22), and specialized Duplex or Super Duplex alloys for enhanced corrosion resistance. Material selection depends on the conveyed media and operating conditions.

-

Q2: Which size standards are commonly applied?A2: Sizes typically range from 1/2" (DN15) up to 48" (DN1200), conforming to standards including ASME B16.5, B16.47, EN 1092-1, and JIS B2220. Custom dimensions for unique projects are also available.

-

Q3: How is the thickness of a slip on weld flange determined?A3: Flange thickness corresponds to the pressure class (e.g., Class 150, 300, etc.) and is specified by relevant standards such as ASME B16.5. Thicker flanges are required for higher-pressure service.

-

Q4: Describe the installation procedure for a slip on flange.A4: The flange is slipped over the pipe to the desired location, then welded both at the pipe's inner and outer edge (fillet welds). This dual-weld ensures mechanical strength and leak prevention.

-

Q5: What are the common facing types?A5: The mainstream facing types include RF (Raised Face), FF (Flat Face), and RTJ (Ring-Type Joint), each offering different sealing capabilities for varied pressure and media requirements.

-

Q6: Can slip on weld flanges be reused in pipeline systems?A6: Yes, they are suitable for repeated disassembly and reassembly, provided the flange is not damaged during use or removal. Always inspect for warping and weld quality before re-use.

-

Q7: What distinguishes slip on weld flanges from weld neck flanges?A7: Slip on weld flanges are more affordable and easier to align, requiring only fillet welds, while weld neck flanges offer higher strength and stress distribution but cost more and require precise butt welding.

Reliability & Quality Commitment | HEBEI JIUYUAN PIPELINE MANUFACTURING CO.,LTD.

As a leading manufacturer and exporter, HEBEI JIUYUAN PIPELINE MANUFACTURING CO.,LTD. empowers clients worldwide with certified, traceable slip on weld flanges. Every product is tested under international protocols such as ASME, EN, and ISO for pressure, leak, and metallurgical integrity. Our flanges are supplied to numerous infrastructure projects across continents—earning global recognition for build quality and trustworthiness.

| Certification | Test | Standard |

|---|---|---|

| ISO 9001:2015 | Ultrasonic, Radiographic | EN 10204 3.1 |

| ASME (USA) | Hydrostatic | ASME B16.5/16.47 |

| CE (Europe) | Dimensional, Visual | EN 1092-1 |

Why Choose Our Slip On Weld Flanges?

- Complete Customization: Sizes, materials, coatings as per project and design code demands.

- On-Time Worldwide Delivery: We maintain strategic stock and advanced logistics.

- Application Engineering: Our technical team offers design, consultation, and after-sales support.

- Full Compliance: Meet or exceed ASME, EN, JIS, ISO, and special client specifications.

For robust, reliable, and tailor-made slip on weld flanges, trust HEBEI JIUYUAN PIPELINE MANUFACTURING CO.,LTD. as your professional partner.

Request a Quote for Slip On Weld Flanges Now

References and Further Reading

- "Slip-On Flange Selection and Fabrication Guidelines", ASME

- "Welding Techniques for Slip-On and Weld Neck Flanges", TWI - The Welding Institute

- "Pipeline Flanges and Fittings - Market Analysis 2023", InTechOpen

- "Industrial Application of Flanges", ResearchGate

- "Industry Forum: Comparison of Flange Types", ENG-TIPS Forum

- "API Standards for Piping Flanges", American Petroleum Institute

- "Guidelines for Quality Management", ISO 9001:2015

-

Apr. 24, 2025

Apr. 24, 2025Jiuyuan Pipeline is excited to announce its participation in the upcoming 2025 Wire / Tube with Metal & Steel KSA exhibition, scheduled from May 5th to May 7th, 2025.

-

Apr. 28, 2025

Apr. 28, 2025From April 15 to April 19, 2025, our company proudly participated in the renowned Canton Fair held in Guangzhou, China.

If you are interested in our products, you can choose to leave your information here, and we will be in touch with you shortly.