- Albanian

- Arabic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bulgarian

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Finnish

- French

- German

- Greek

- Hebrew

- Hungarian

- Indonesian

- irish

- Italian

- Japanese

- Khmer

- Korean

- Kyrgyz

- Lao

- Latin

- Lithuanian

- Malay

- Myanmar

- Norwegian

- Persian

- Polish

- Portuguese

- Romanian

- Russian

- Serbian

- Slovak

- Slovenian

- Spanish

- Swedish

- Tagalog

- Thai

- Turkish

- Turkmen

- Uzbek

- Vietnamese

- Zulu

Steel Tubes In The Chemical & Petrochemical Industry

Process Piping Systems

In chemical and petrochemical plants, steel tubes form the backbone of process piping systems that transport raw materials, intermediate products, and finished chemicals. These piping systems must handle a variety of fluids, including corrosive acids, solvents, hydrocarbons, and gases under varying pressure and temperature conditions. Carbon steel, stainless steel, and alloy steel tubes are chosen based on the chemical composition and operating conditions to ensure durability and resistance to corrosion, erosion, and thermal stress.

Heat Exchangers and Boilers

Steel tubes are widely used in heat exchangers and boilers, critical equipment for temperature control in chemical processes. Heat exchangers transfer heat between two fluids without mixing them, often involving corrosive or high-temperature substances. The tubes must exhibit excellent thermal conductivity, corrosion resistance, and mechanical strength to withstand thermal cycling and high-pressure conditions. Stainless steel and alloy tubes are preferred for their ability to resist scaling, fouling, and corrosion.

Pressure Vessels and Reactors

Pressure vessels and chemical reactors are essential components where steel tubes are used to construct internal tubing, coils, or jackets that facilitate chemical reactions under controlled pressure and temperature. The steel tubes must meet stringent standards to prevent leaks, withstand internal pressures, and resist chemical attack. High-grade alloy steels and stainless steels are commonly used, often with special surface treatments or linings to enhance corrosion resistance.

Storage and Transfer Systems

Steel tubes are critical for storage tanks and transfer pipelines that handle various chemicals and petrochemical products. These tubes connect tanks to processing units and distribution networks, requiring leak-proof and corrosion-resistant solutions. The tubes must maintain structural integrity under fluctuating pressures and exposure to aggressive chemicals, often necessitating the use of corrosion-resistant alloys or protective coatings.

Cryogenic and High-Temperature Applications

Certain chemical and petrochemical processes involve extremely low or high temperatures. Steel tubes used in cryogenic systems, such as liquefied natural gas (LNG) handling and storage, must retain toughness at very low temperatures to prevent brittle failure. Conversely, tubes used in high-temperature furnaces or reactors must resist thermal expansion and oxidation. Specialized stainless steels and nickel-based alloys are typically employed to meet these challenges.

Safety and Environmental Systems

Steel tubes also play a role in safety and environmental control systems within chemical plants. They are used in flare lines, vent systems, and scrubbers designed to safely handle excess gases or emissions. These applications demand steel tubes that can resist corrosion from acidic or toxic gases and withstand pressure surges, ensuring safe plant operation and environmental compliance.

Steel tubes are indispensable in the chemical and petrochemical industries, supporting complex processes that require robust, reliable, and corrosion-resistant materials. Their versatility in handling diverse chemical media, extreme temperatures, and pressures makes them essential for the safe and efficient operation of modern chemical plants. Advances in metallurgy and manufacturing continue to enhance the performance of steel tubes, enabling the industry to meet increasingly stringent safety and environmental standards.

-

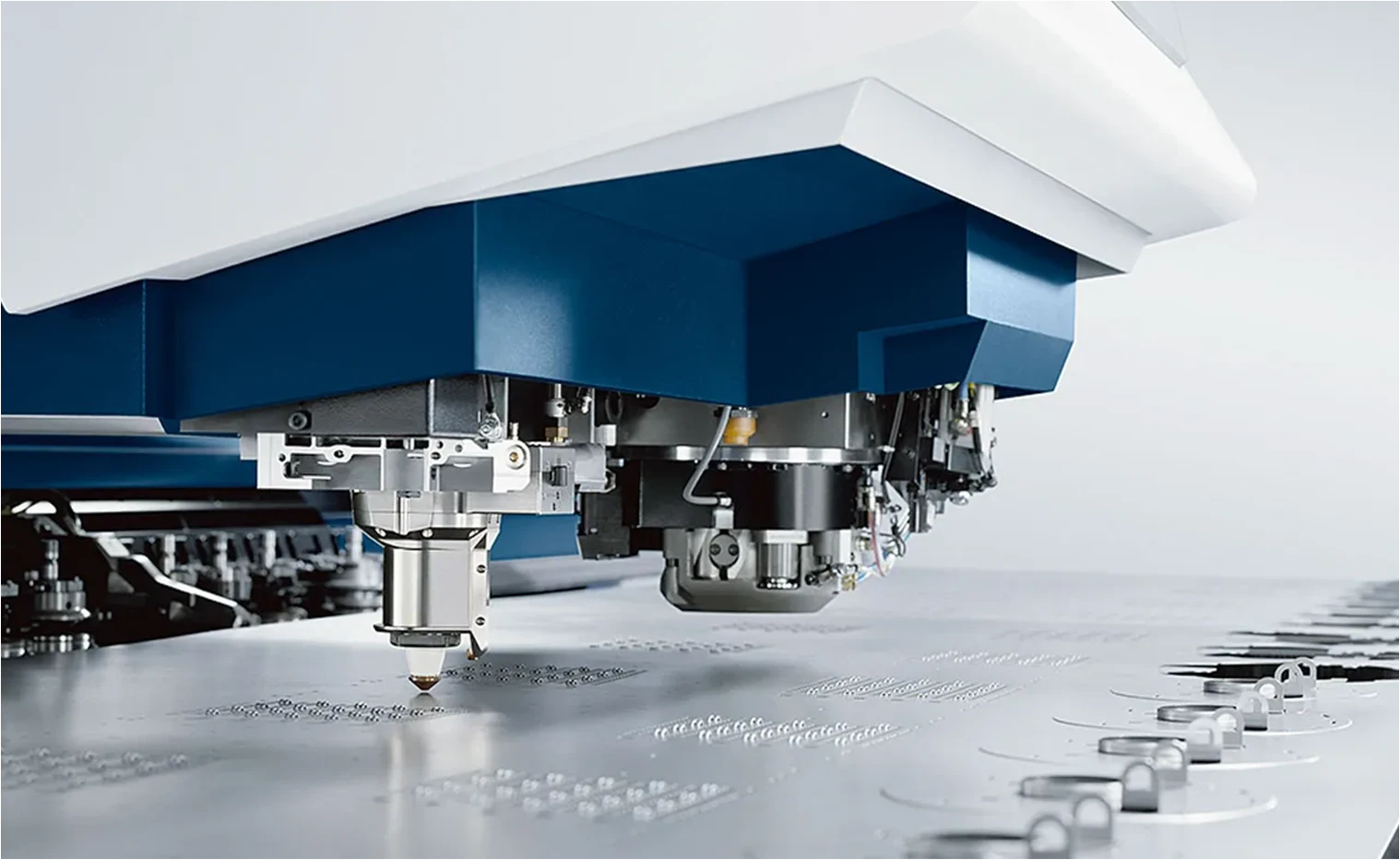

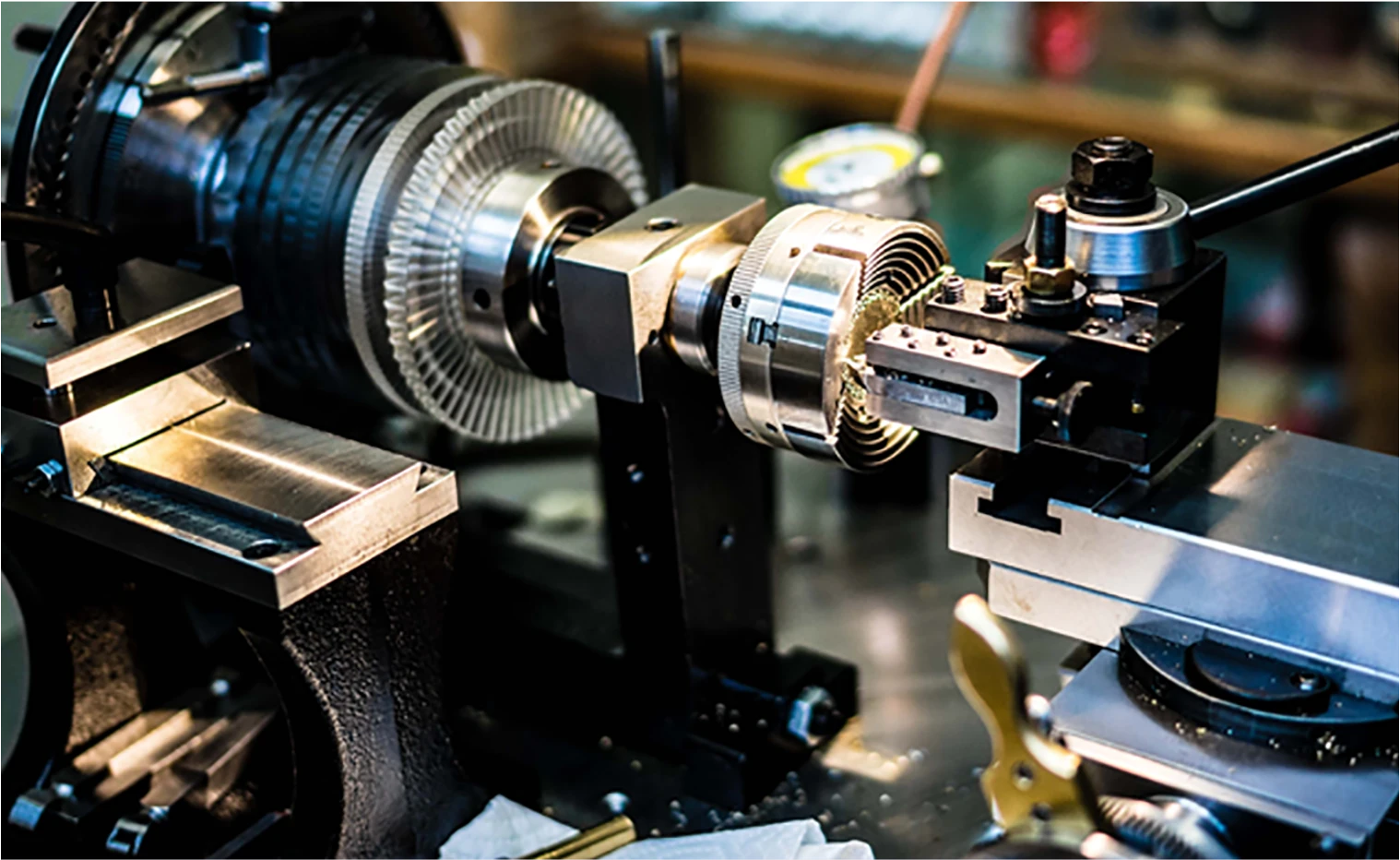

CNC Machining1By using CNc milling & turning, wecan make a wide range of prototypes and production parts1

CNC Machining1By using CNc milling & turning, wecan make a wide range of prototypes and production parts1

Producing reliable aerospace part prototypes is a task that relies on accuracy, quality, and strictly adhering to specifications. For the years while we have specialized in aerospace prototyping, we have gathered expertise to produce all kinds of aerospace parts, whether simple or complex. 3ERP conducts numerous quality checks and testing that all the parts produced must be satisfied by our customers, as well as undergo the most rigorous certification and testing procedures. Request a quote for your designs or contact us for information about how we can work with you in your area of the medical industry.

Producing reliable aerospace part prototypes is a task that relies on accuracy, quality, and strictly adhering to specifications. For the years while we have specialized in aerospace prototyping, we have gathered expertise to produce all kinds of aerospace parts, whether simple or complex. 3ERP conducts numerous quality checks and testing that all the parts produced must be satisfied by our customers, as well as undergo the most rigorous certification and testing procedures. Request a quote for your designs or contact us for information about how we can work with you in your area of the medical industry.

Producing reliable aerospace part prototypes is a task that relies on accuracy, quality, and strictly adhering to specifications. For the years while we have specialized in aerospace prototyping, we have gathered expertise to produce all kinds of aerospace parts, whether simple or complex. 3ERP conducts numerous quality checks and testing that all the parts produced must be satisfied by our customers, as well as undergo the most rigorous certification and testing procedures. Request a quote for your designs or contact us for information about how we can work with you in your area of the medical industry.

-

Aug. 22, 2025

Aug. 22, 2025HEBEI JIUYUAN PIPELINE MANUFACTURING CO.,LTD. is located in Mengcun Hui Autonomous County, known as

-

Apr. 24, 2025

Apr. 24, 2025Jiuyuan Pipeline is excited to announce its participation in the upcoming 2025 Wire / Tube with Metal & Steel KSA exhibition, scheduled from May 5th to May 7th, 2025.

If you are interested in our products, you can choose to leave your information here, and we will be in touch with you shortly.