- Ukufakwa Kwepayipi

- Cast Products

- HEXAGON NUT (LN)

- WELDING NPPLE (WN)

- SOCKET PLAIN (SPU)

- COUPLING O.D.MACHINED (SPE)

- 90 ELBOW(90LB)

- 45 ELBOW(45LB)

- CAP (CB)

- BARREL NIPPLE (BN)

- SOCKET BANDED(SB)

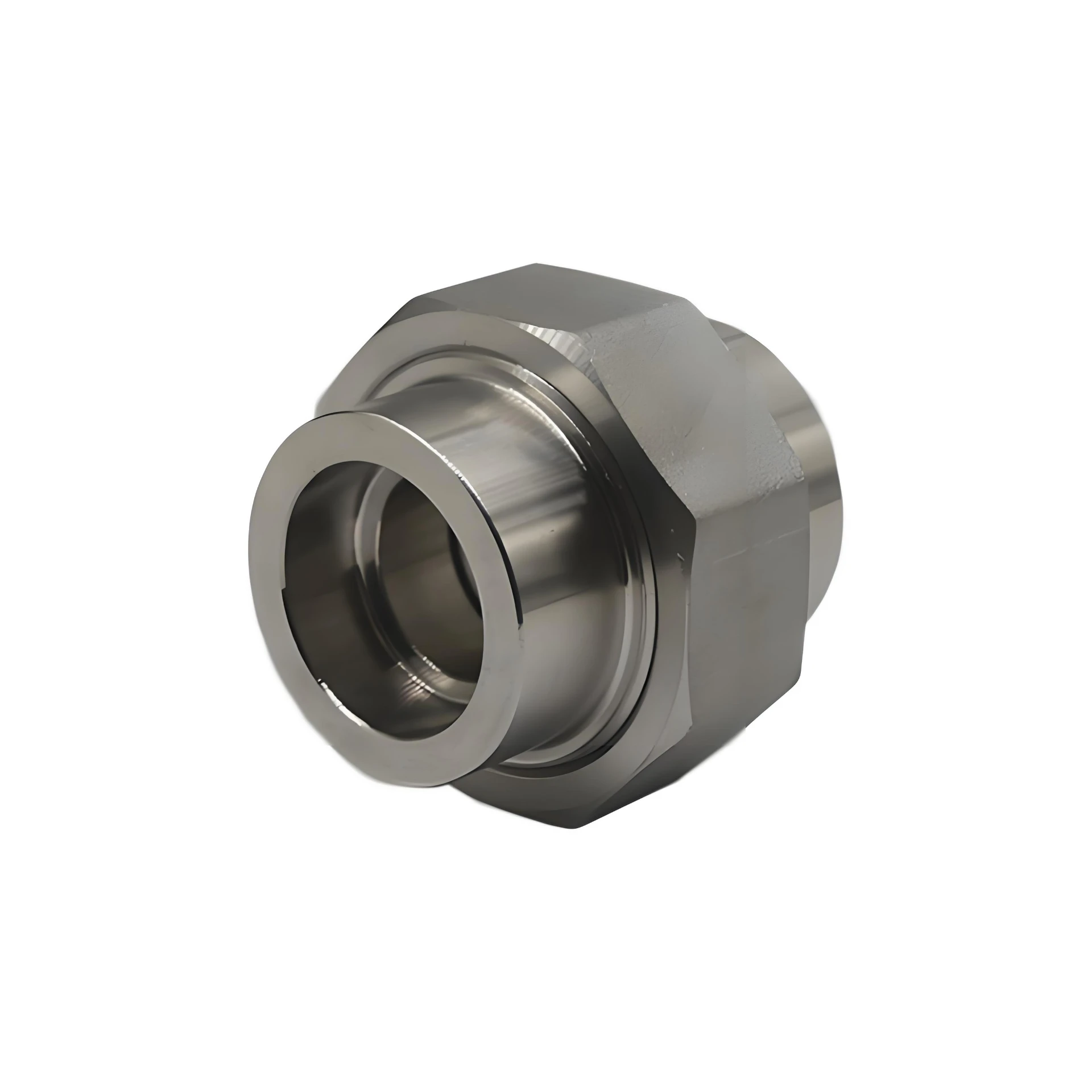

- UNION(CU)

- REDUCING SOCKET BANDED (RSB)

- REDUCING TEE (RTB)

- REDUCING HEXAGON NIPPLE(RHN)

- SQUARE PLUG (SQ)

- CROSS (十B)

- TEE(TB)

- HOSE NIPPLE (HON)

- UNION M,F(CU MF)

- HEXAGON NIPPLE(HN)

- HEXAGON PLUG (HP)

- HEXAGON HEAD CAP(HCB)

- HEXAGON BUSHING(HB)

- Forged Products

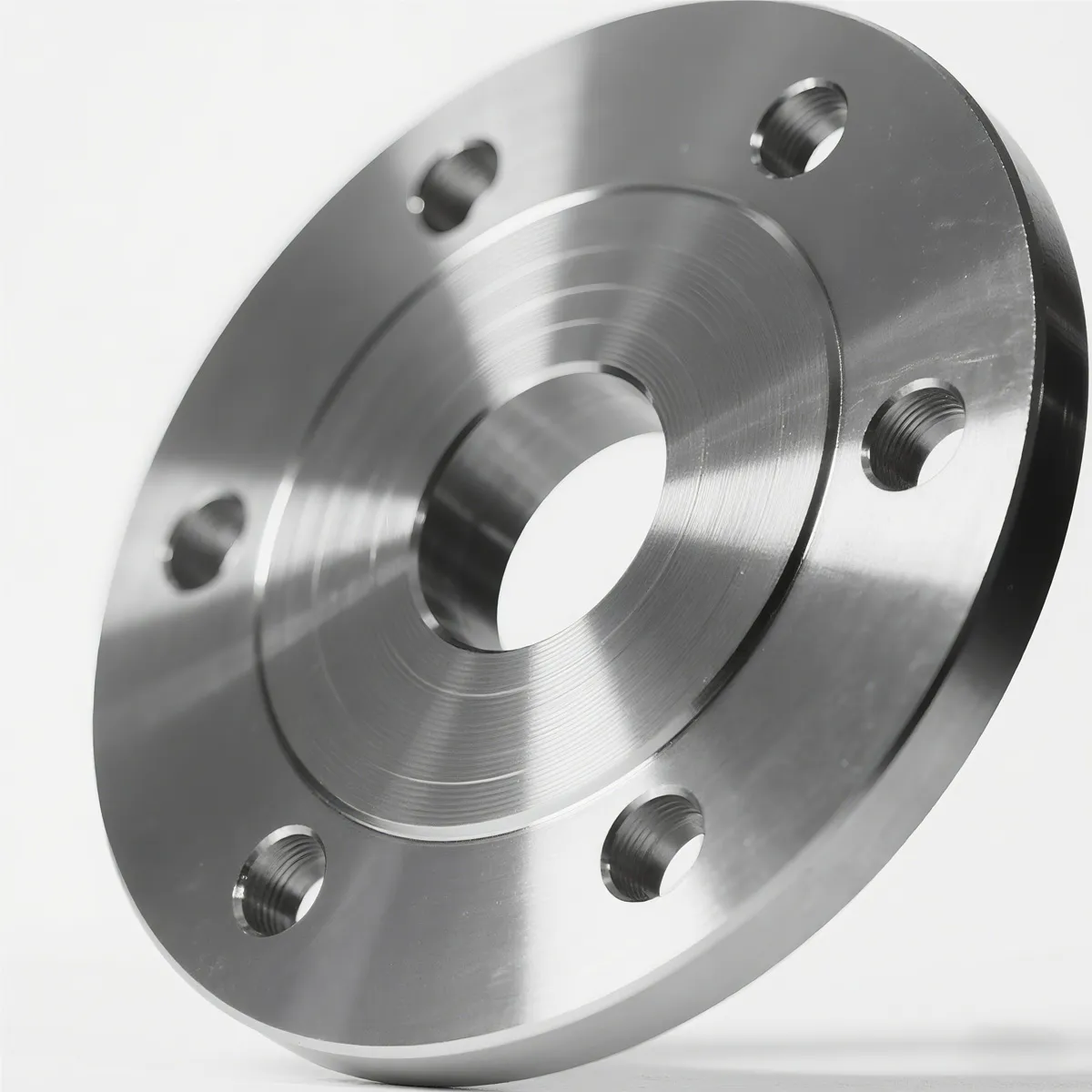

- I-Flange

Izindololwane zamapayipi ziwukufakwa okubalulekile okusetshenziselwa ukushintsha isiqondiso sokugeleza ezinhlelweni zamapayipi, ngokuvamile kuma-engeli angu-45°, 90°, noma angu-180°. Idizayinelwe ukuguquka kokugeleza okushelelayo, inciphisa ukulahleka kwengcindezi kanye nesiyaluyalu. Kutholakala kumarediya ahlukahlukene (irediyasi emfishane kanye nerediyasi ende), izindololwane zingamukela izidingo zokufakwa ezihlukene kanye nezingqinamba zesikhala.

|

Izindololwane |

|

Incazelo: Izindololwane |

|

Uhlobo: Irediyasi Ede: 45°/90°/180° Irediyasi emfushane: 90°/180° |

|

DN/INCH: (inde) ½Ngaphakathi - 48In/(ifushane)½Ngaphakathi - 24In |

|

MAR:CS(ASTM A105P235GH/P245GH/P250GH/P265GH/ST37-2)SS(ASTM A182/304/306) |

|

STD: ASME/ANSI/B16.9/B16.28/ΓOCT 17375-2001/ZU/DIN/JIS |

|

Surface Coating:Black paint/Galvanize/Grease/Epoxy paint |

|

Ngodonga oluwugqinsi kunokufakwa kwepayipi lethu elijwayelekile le-butt-weld, lezi zinikeza amandla aphezulu kuyilapho zinikeza uxhumo olubushelelezi lokugeleza okuphezulu. Zineziphetho ezigobekile okuthi, uma zishaywa ngamapayipi, zenze umkhombe wokushisela ongavuzi, unomphela. |

Izindololwane zamapayipi ziwukufakwa okubalulekile okusetshenziselwa ukushintsha isiqondiso sokugeleza ezinhlelweni zamapayipi, ngokuvamile kuma-engeli angu-45°, 90°, noma angu-180°. Idizayinelwe ukuguquka kokugeleza okushelelayo, inciphisa ukulahleka kwengcindezi kanye nesiyaluyalu. Kutholakala kumarediya ahlukahlukene (irediyasi emfishane kanye nerediyasi ende), izindololwane zingamukela izidingo zokufakwa ezihlukene kanye nezingqinamba zesikhala. Akhiwe ngezinhlobonhlobo zezinto—njenge-carbon steel, insimbi engagqwali, i-alloy steel, ne-PVC—zinikeza ukuqina okuhle kakhulu, ukumelana nokugqwala, namandla okusebenza. Izindololwane zamapayipi zikhiqizwa ngokuya ngamazinga omhlaba afana ne-ASME, i-DIN, i-JIS, ne-EN, okuqinisekisa ukuhambisana nokusebenza okuphezulu ezimbonini eziningi ezihlanganisa uwoyela negesi, ukucubungula amakhemikhali, ukuphehlwa kukagesi, nokwelashwa kwamanzi.

Izindololwane zamapayipi Isicelo

Izindololwane zamapayipi zisetshenziswa kakhulu ezinhlelweni zamapayipi ukushintsha isiqondiso sokugeleza, ngokuvamile kuma-engeli angu-45°, 90°, noma angu-180°. Ziyizingxenye ezibalulekile ezimbonini ezinjengowoyela negesi, amakhemikhali e-petrochemicals, izimboni zamandla kagesi, ukwelashwa kwamanzi, i-HVAC, kanye nokwakhiwa kwemikhumbi. Izindololwane zivumela amaphayiphi ukuthi azulazule eduze nezithiyo, alingane phakathi kwezakhiwo, futhi agcine izindlela zokugeleza eziphumelelayo. Kumasistimu anomfutho ophezulu noma izinga lokushisa eliphezulu, izindololwane ezenziwe ngezinto ezihlala isikhathi eside njengensimbi engagqwali noma i-alloy steel ziqinisekisa ukusebenza nokuphepha kwesikhathi eside. Kungakhathaliseki ukuthi ezokuthutha uketshezi, amagesi, noma ama-slurries, izindololwane zamapayipi zidlala indima ebalulekile ekugcineni isiqondiso sokugeleza kanye nobuqotho besistimu.

Yiziphi izinhlobo ezahlukene zezindololwane?

Izindololwane zamapayipi ziza ngezinhlobo ezahlukene, ngayinye yakhelwe ukushintsha indlela yokuhamba ngayo ohlelweni lwamapayipi. Izinhlobo ezivame kakhulu yilezi 90-degree izindololwane, 45-degree izindololwane, futhi 180-degree ukugoba ukubuya. Indololwane engu-90-degree ishintsha isiqondiso sokugeleza nge-engeli engakwesokudla futhi isetshenziswa kakhulu kumapayipi lapho kudingeka khona isikhala namashifu aqondisayo. Indololwane ye-45-degree idala uguquko olushelelayo lwendlela, oluvame ukusetshenziselwa ukunciphisa ukulahleka kwengcindezi noma isiyaluyalu.

Izindololwane nazo zihlukaniswa ngokwazo i-radius ye-curvature: irediyasi emfushane (SR) izindololwane futhi irediyasi ende (LR) izindololwane. Amandololwane erediyasi emfushane anokushintshana okuqinile, alungele izindawo ezihlangene kodwa ngokwehla kwengcindezi ephezulu. Amandololwane erediyasi amade anikeza ijika elithambile, elinciphisa ukumelana nokugeleza nokuguga, futhi akhethwa ezinhlelweni zokugeleza okuphezulu.

Ngokwezinto ezibonakalayo, izindololwane ziyatholakala insimbi ye-carbon, insimbi engagqwali, insimbi ye-alloy, futhi ipulasitiki (I-PVC noma i-CPVC), ekhethwe ngokusekelwe ezidingweni zohlelo lokusebenza ezifana nokucindezela, izinga lokushisa, nokumelana nokugqwala. Amazinga afana ne-ASME B16.9 noma i-DIN abusa ubukhulu nokusebenza kwawo.

Sekukonke, ukukhetha uhlobo olulungile lwendololwane kuqinisekisa ukugeleza okusebenzayo, ukwethembeka kwesistimu, nokuhambisana nezidingo zokusebenza kumasistimu amapayipi ezimboni, ezentengiselwano, noma zokuhlala.

Yiziphi izigaba ezine zezindololwane?

Izindololwane ezinhlelweni zamapayipi zingahlukaniswa ngezigaba ezine eziyinhloko ngokusekelwe i-angle, irediyasi, qeda ukuxhumana, futhi impahla.

Nge-Engeli: Ama-engeli endololwane avame kakhulu 90-degree, 45-degree, futhi 180-degree (okubizwa nangokuthi ama-return bend). Lokhu kuchaza indlela ipayipi elijika ngayo lishintsha kakhulu.

Nge-Radius: Izindololwane zihlukaniswa njenge I-Long Radius (LR) and Irediyasi emfushane (SR). Amandololwane erediyasi amade anobubanzi obuphakathi nendawo izikhathi ezingu-1.5 ubukhulu bepayipi, enikeza ukugeleza okushelelayo nokulahlekelwa kwengcindezi encane. Amandololwane erediyasi emfushane anobubanzi obulingana nobubanzi bepayipi futhi asetshenziswa ezindaweni eziqinile.

Ngokuqeda Ukuxhumana: Izindololwane zingaba nezinhlobo ezahlukene zokugcina, njenge i-butt-weld, isokhethi-weld, noma intambo. Izindololwane ze-butt-weld zishiselwa ngqo epayipini, kuyilapho izindololwane ze-socket-weld kanye nezintambo zivame ukusetshenziswa ngobubanzi obuncane noma izinhlelo zokusebenza zokucindezela okuphezulu.

Ngempahla: Izindololwane zenziwa ngezinto ezihlukahlukene kuhlanganise insimbi ye-carbon, insimbi engagqwali, insimbi ye-alloy, ithusi, futhi ipulasitiki (i-PVC, i-CPVC), ekhethiwe ngokusekelwe kuketshezi, izinga lokushisa, nezimo zengcindezi.

Ukuqonda lezi zigaba ezine kusiza onjiniyela bakhethe uhlobo olulungile lwendololwane ukuze baqinisekise ukusebenza kwesistimu yamapayipi ephephile, ephumelelayo, futhi eqinile.